Elevator control device

A technology of elevator control device and speed control device, which is applied in the direction of AC motor control, control system, vector control system, etc., can solve problems such as power converter capacity constraints, and achieve improved noise resistance, increased freedom, and simple wiring Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

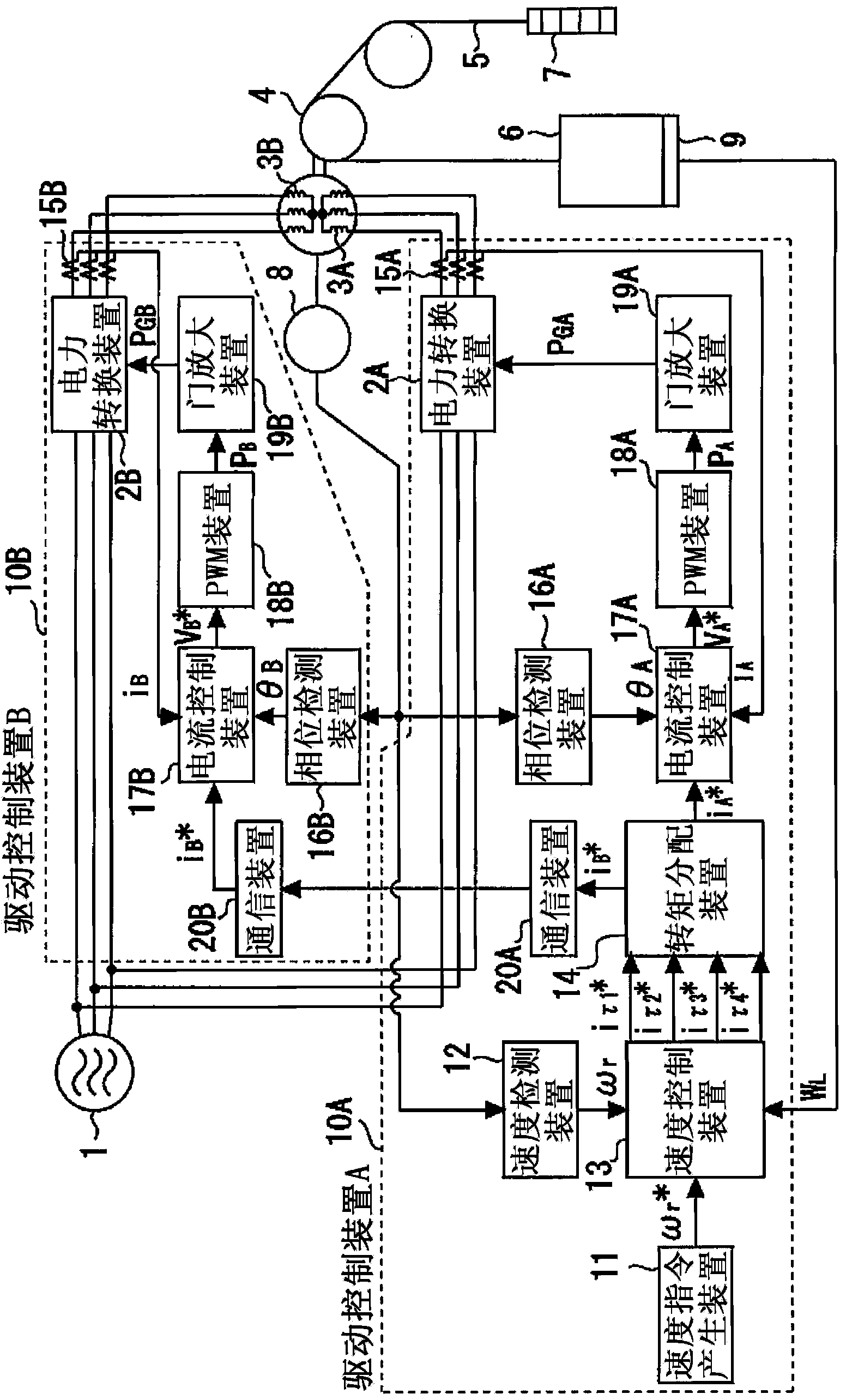

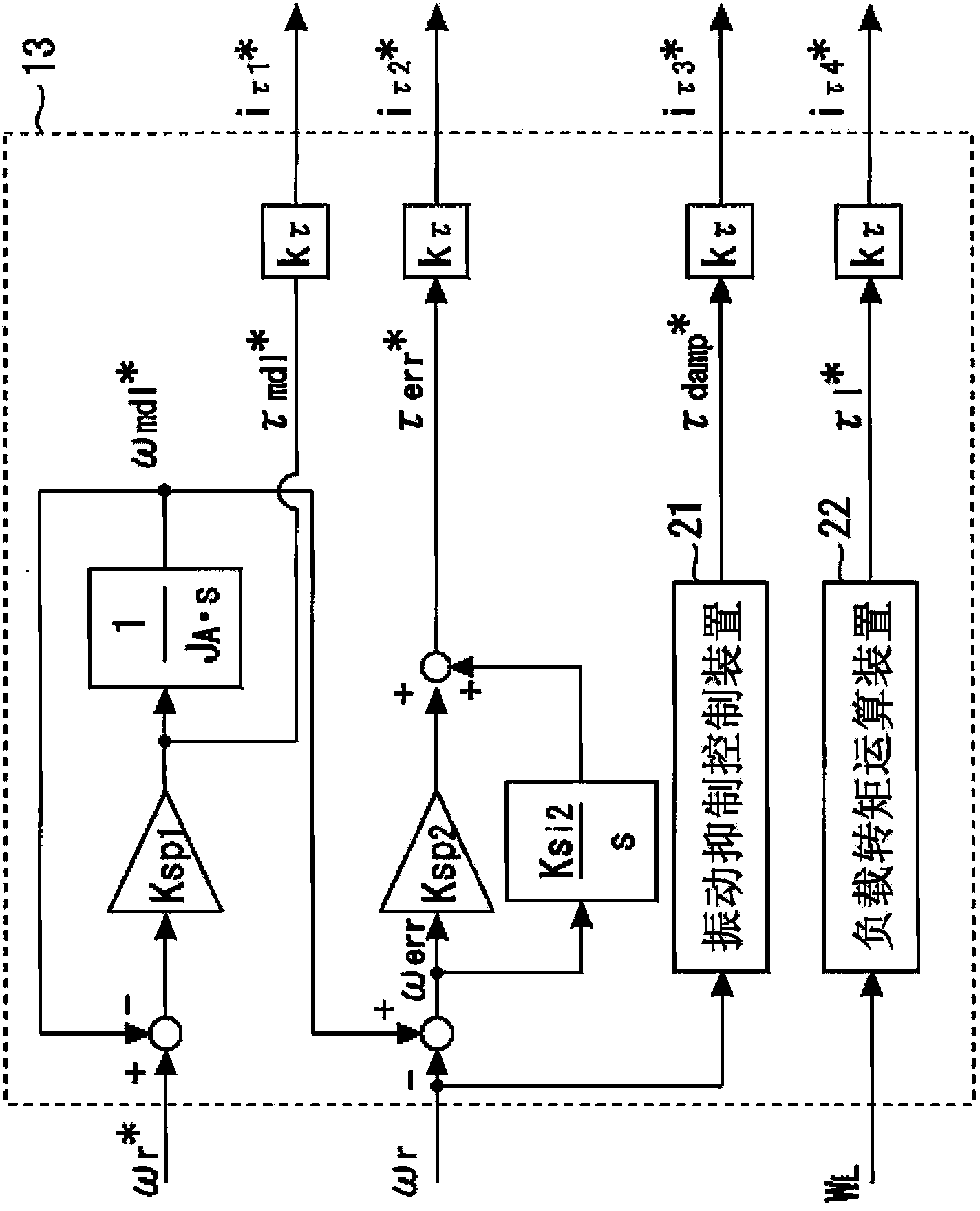

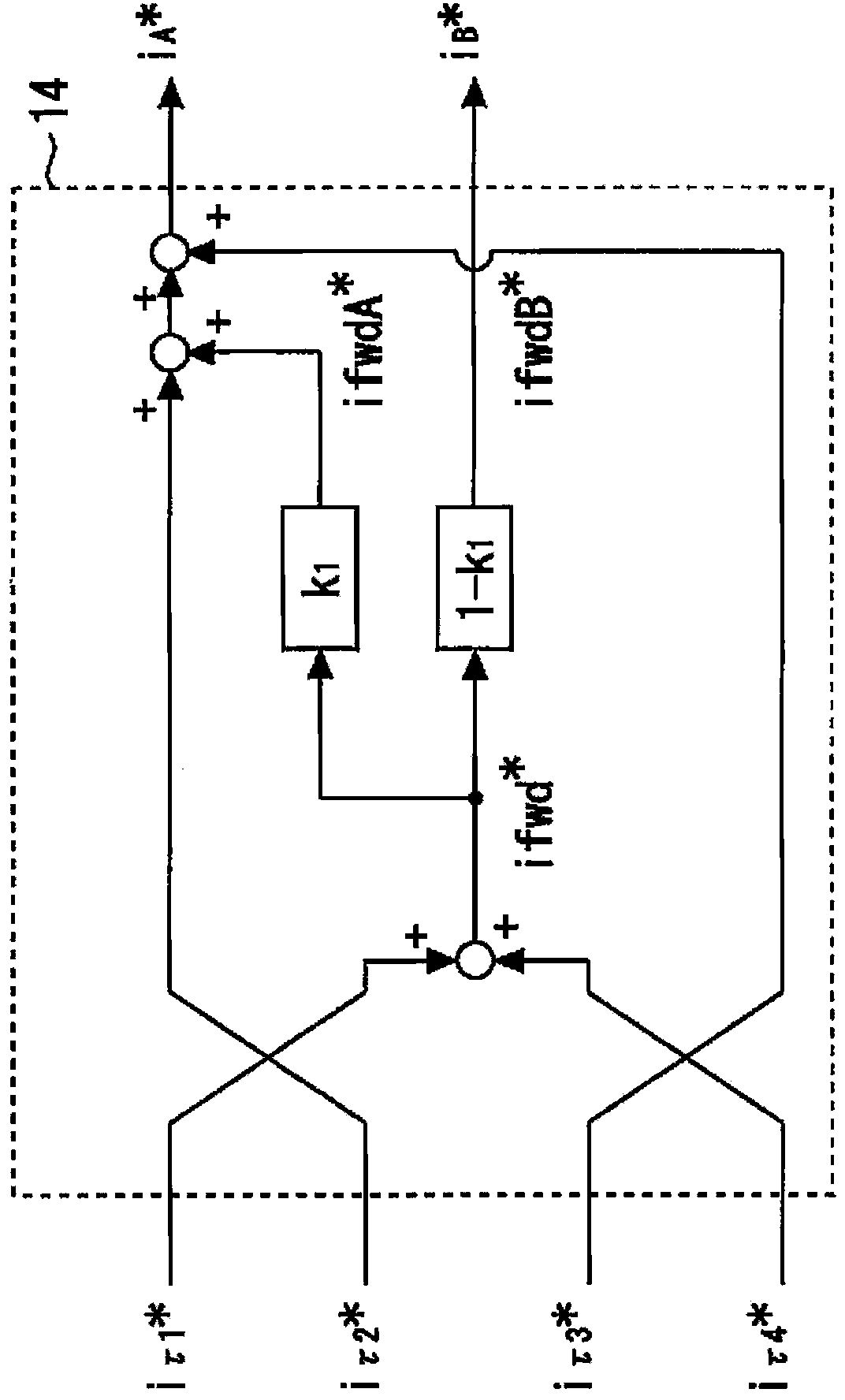

[0027] Figure 1 ~ Figure 3 Regarding Embodiment 1 of the present invention, figure 1 is a system configuration diagram showing the overall configuration of the elevator control device, figure 2 is an explanatory diagram showing the internal structure of the speed control device, image 3 It is an explanatory diagram showing the internal structure of the torque distribution device.

[0028] In the figure, 1 is a commercial power supply which is a three-phase AC power supply for supplying electric power to the elevator. The three-phase AC power from the commercial power supply 1 is input to the first power conversion device 2A and the second power conversion device 2B respectively, and the voltage and frequency are respectively converted in the first power conversion device 2A and the second power conversion device 2B. Variable voltage and variable frequency alternating current are output separately.

[0029] The AC power output from the first power conversion device 2A is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com