Tunable semiconductor laser unit

A laser and semiconductor technology, which is applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve the problems of inconsistent output optical power, etc., and achieve the effects of fast wavelength dynamic switching, easy production, and narrow spectral line width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

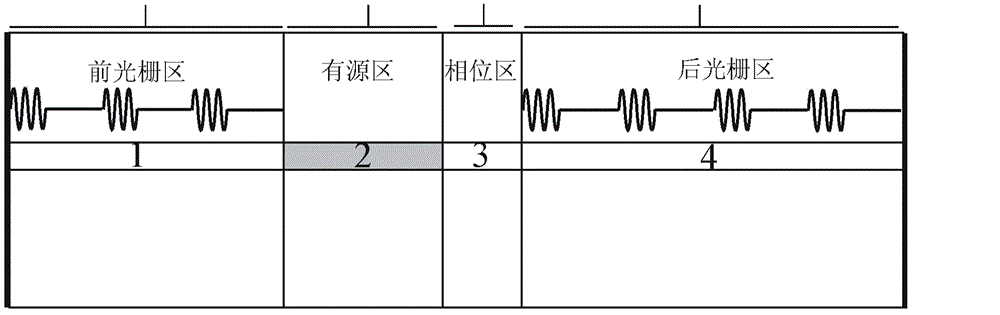

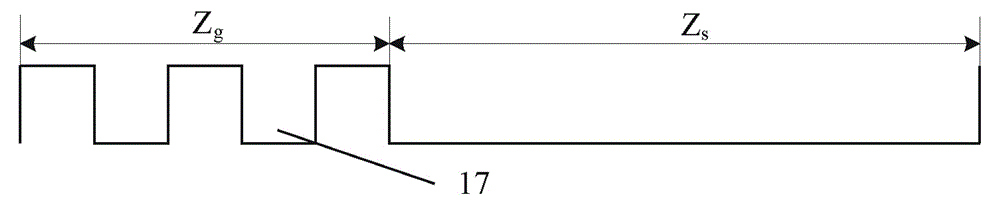

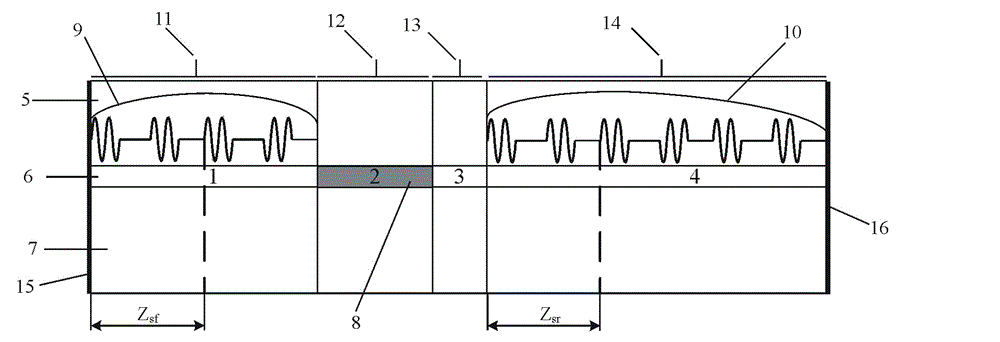

[0052] In the first implementation example, the front and rear Bragg gratings 9 and 10 all adopt two sets of interleaved multi-phase shift sampling gratings, with Figure 5 It is a schematic structural diagram of the front and rear interleaved multi-phase-shift sampling gratings of the first implementation example, and from top to bottom are the first and second groups of multi-phase-shift sampling gratings. For the front and rear Bragg gratings 9, 10, according to the formula , m=2, i=1, 2. The grating initial phase difference between adjacent sampling periods of the first group of multi-phase shift sampling gratings is =0, the initial phase difference of the grating during the adjacent sampling period of the second group of multi-phase shift sampling grating is = π, two groups of interleaved multi-phase-shift sampling gratings have the same grating period and sampling period. See the dotted arrow in the direction from the second group of multi-phase-shift sampling grat...

Embodiment 2

[0057] In the second implementation example, the front and rear Bragg gratings 9 and 10 all adopt three sets of interleaved multi-phase shift sampling gratings, with Figure 9 It is a schematic structural diagram of the front and rear interleaved multi-phase shift sampling gratings of the second implementation example. From top to bottom are the second, first and third groups of multi-phase shift sampling gratings respectively. For the front and rear Bragg gratings 9, 10, according to the formula , m=3, i=1, 2, 3. The grating initial phase difference between adjacent sampling periods of the first group of multi-phase shift sampling gratings is =0, the initial phase difference of the grating during the adjacent sampling period of the second group of multi-phase shift sampling grating is =2π / 3, the grating initial phase difference between adjacent sampling periods of the third group of multi-phase shift sampling gratings is =4π / 3. The second and third groups of multi-pha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com