Side-in type backlight module

一种侧入式背光、模组的技术,应用在侧入式背光模组领域,能够解决显示面板变形破裂、导光板变形、光学膜片组变形等问题,达到避免自由活动空间、避免翘曲的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

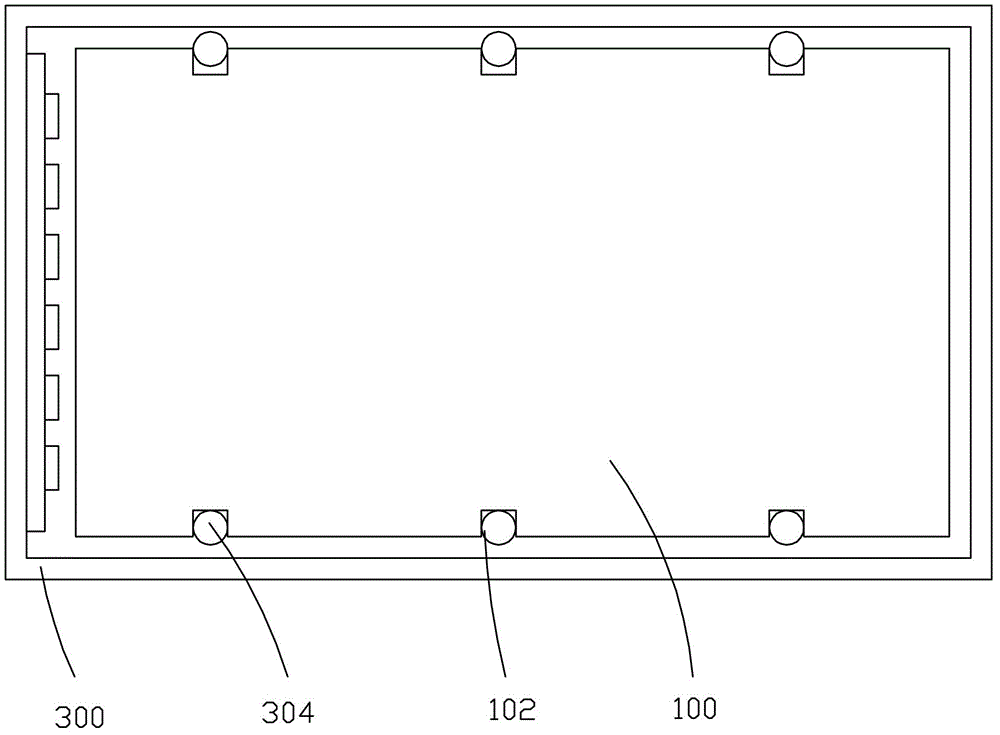

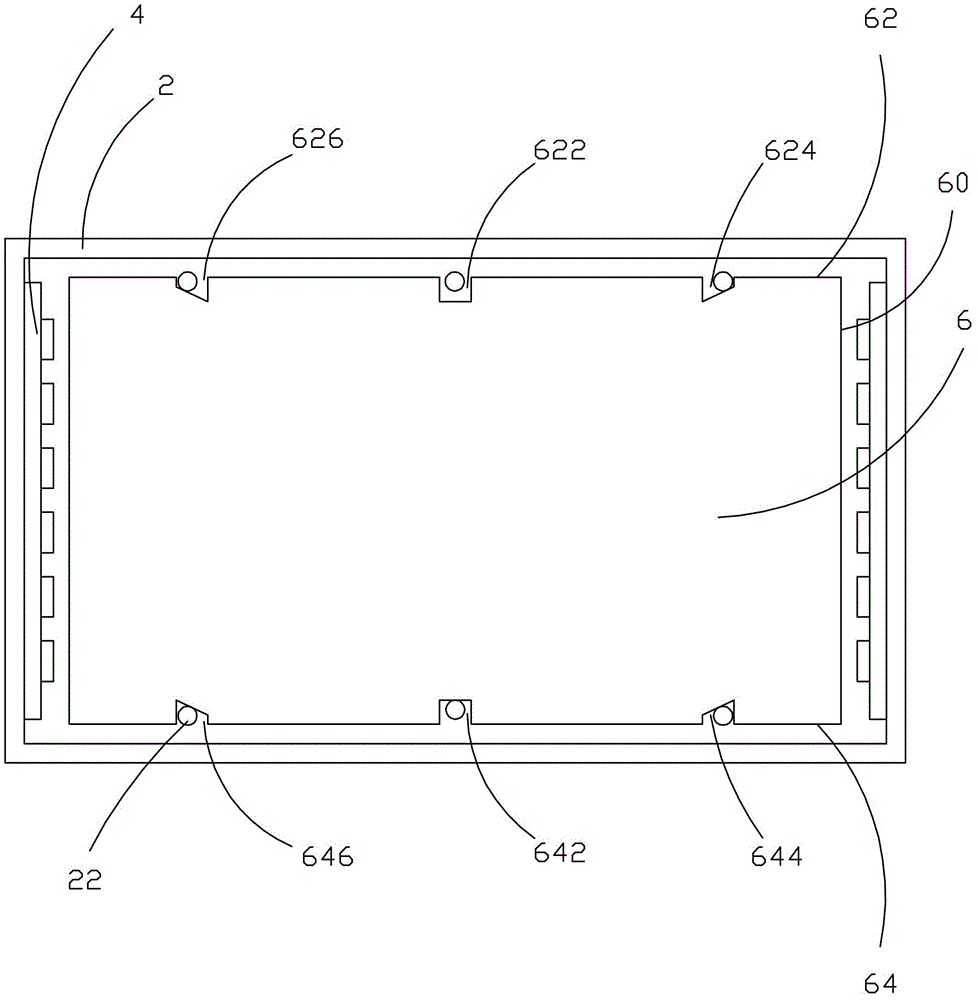

[0024] see image 3 , the present invention provides a side-type backlight module, which is a backlight module with double-sided light input, which includes: a backplane 2, two backlight sources 4 that are relatively arranged in the backplane 2, and a The light guide plate 6 inside the board 2 and between the two backlight sources 4 .

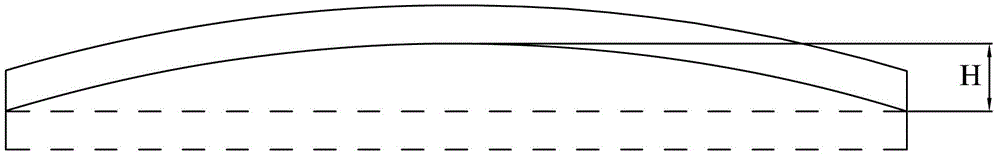

[0025] The light guide plate 6 has two opposite light-incident sides 60, and a first installation side 62 and a second installation side 64 located between the two light-incident sides 60 and oppositely arranged. The light side 60 is provided. Typically, in use, the first mounting side 62 is positioned upwards and the second mounting side 64 is positioned downwards. The first mounting side 62 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com