Multi-functional tunnel operation trolley

A multi-functional, workbench technology, applied in tunnels, tunnel linings, shaft linings, etc., can solve problems such as long installation time of a single arch, influence on tunnel construction progress, and high work intensity of workers, so as to save construction time and improve safety The effect of improvement and labor reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

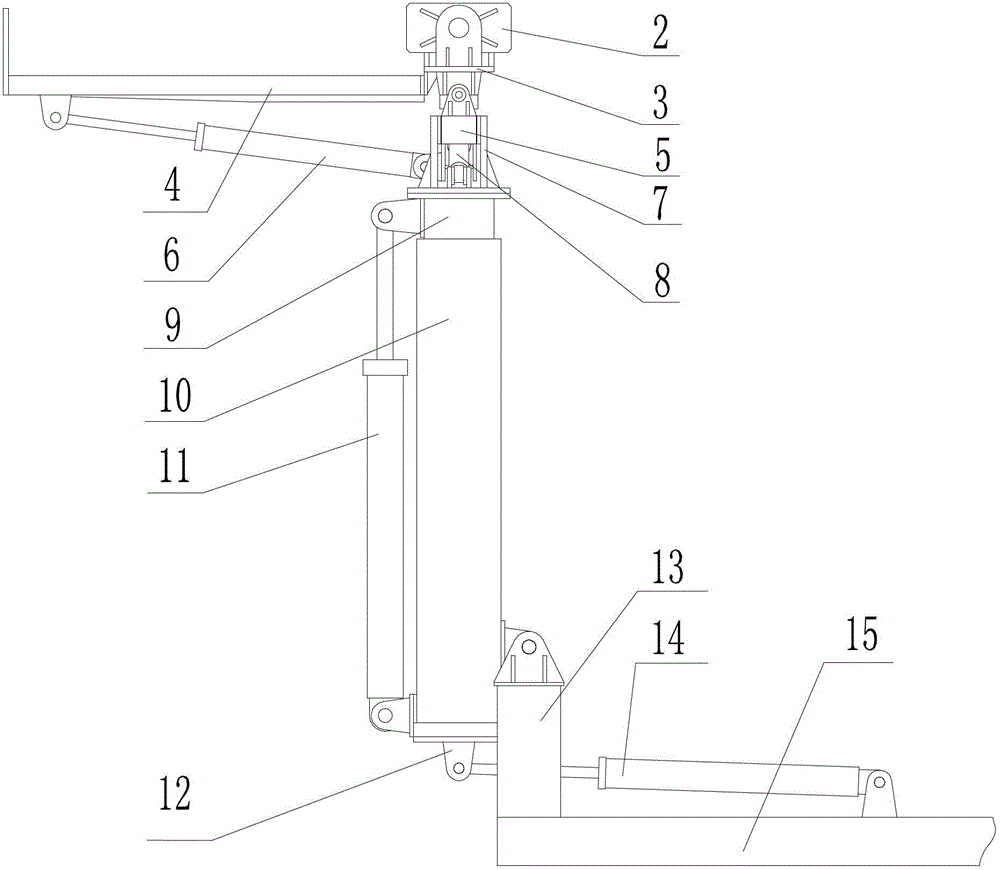

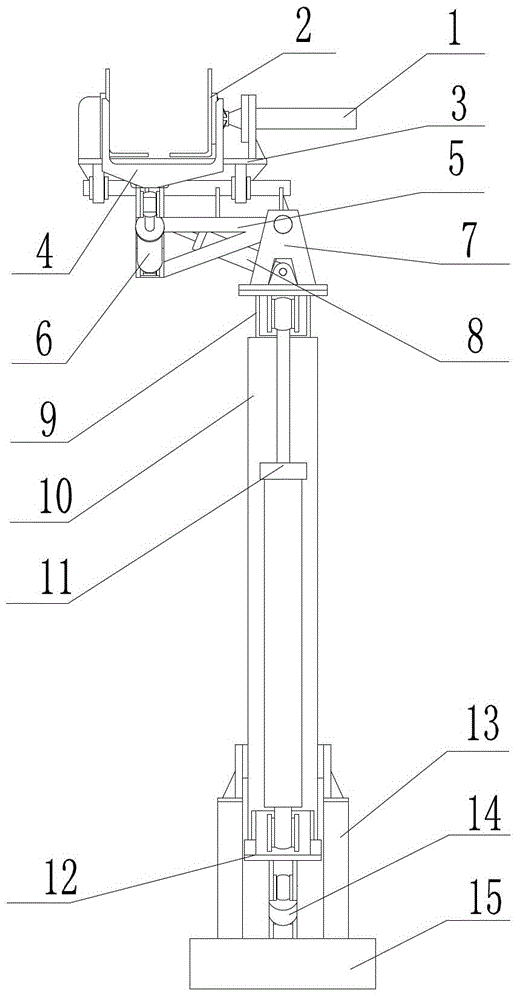

[0013] Such as figure 1 Shown, a kind of tunnel multi-function operation trolley, mainly by chassis 23, host platform 22, the chassis 23 of double swing arm 20, tunnel operation vehicle adopts commonly used excavator chassis, host platform 22 is installed on the chassis 23; The main engine platform 22 is connected to the double boom 20 through a hinge, and the double boom 20 is rigidly connected by two connecting bridges. The two ends of 21 are respectively hinged with the host platform 22 and the double boom 20, the end of the double boom 20 is hinged to the installation platform 15, and a leveling hydraulic cylinder 19 is set between the installation platform 15 and the double boom 20 connecting bridge, the The leveling cylinder 19 is respectively hinged with the double boom 20 and the installation platform 15, so that the installation platform 15 rotates relative to the double boom 20 under the drive of the leveling cylinder 19; under the cooperation of the boom cylinder 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com