Method for preparing mesoporous SiO2/CdS composite nanosphere

A nanosphere and mesoporous technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of semiconductor CdS photocatalysts, such as the presence and small specific surface area, and achieve convenient scale, Simple equipment and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

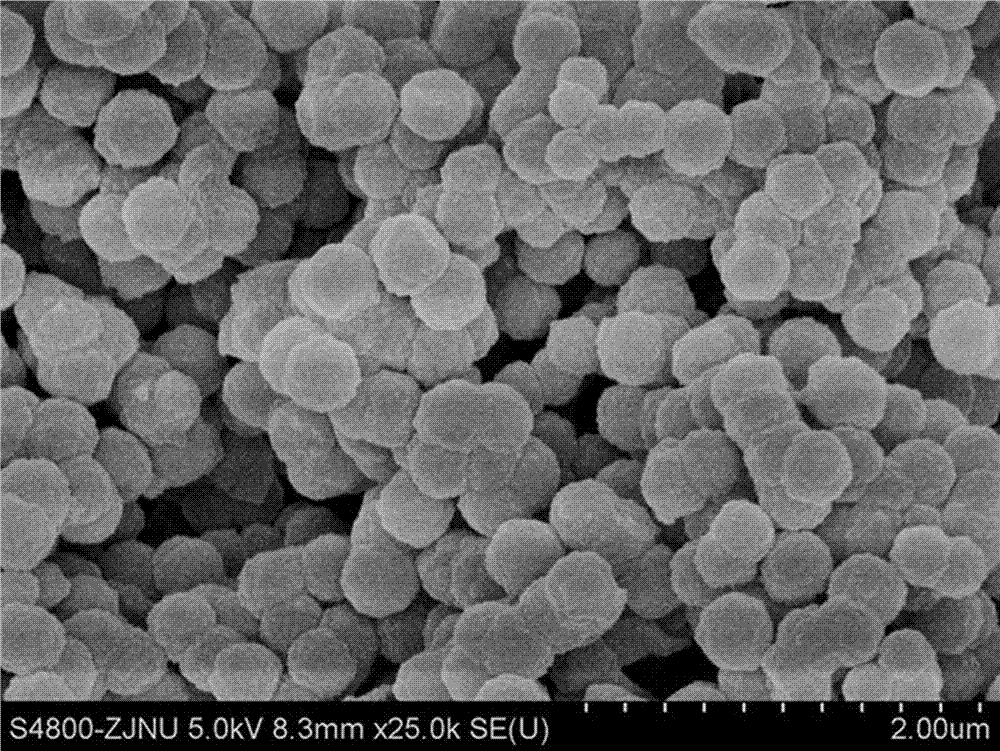

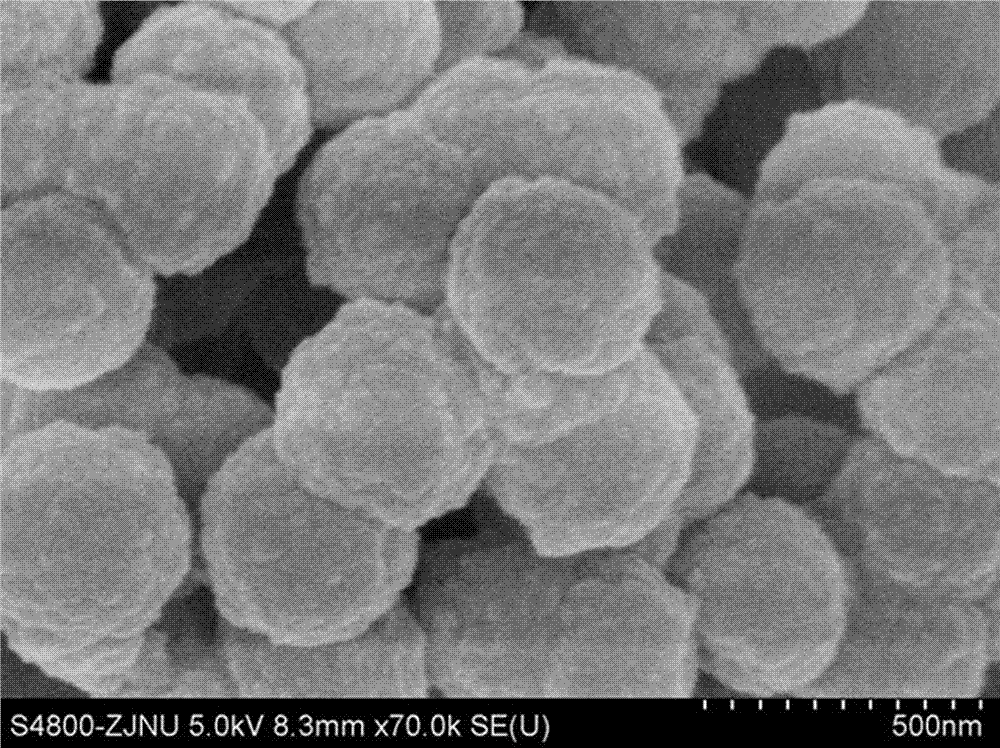

[0060] A preparation of mesoporous SiO 2 The method for / CdS composite nanosphere, its step is:

[0061] (1) Add 44.5g tetraethyl orthosilicate, 16.8g octadecyltrimethoxysilane, 30g ammonia water (mass concentration 25%-28%) into 100 ml ethanol, stir to obtain a milky mixture, and mix the The obtained milky solution was sealed, the temperature was controlled at 90°C, and the reaction was carried out for 12 hours. The product was obtained by centrifugation, and the product was washed three times with absolute ethanol to obtain SiO 2 nanospheres;

[0062] (2) Take the above SiO 2 12g nanospheres, dispersed in 100 ml ethanol solution, add 50g hydrazine hydrate (mass concentration 85%), 2.7g cadmium nitrate, 1.5g thiourea; react the solution at 90°C for 24 hours, and obtain SiO after centrifugation 2 / CdS composite nanosphere;

[0063] (3) The resulting SiO 2 / CdS composite nanospheres were calcined at 900°C for 4 hours to obtain mesoporous SiO 2 / CdO composite nanospheres; ...

Embodiment 2

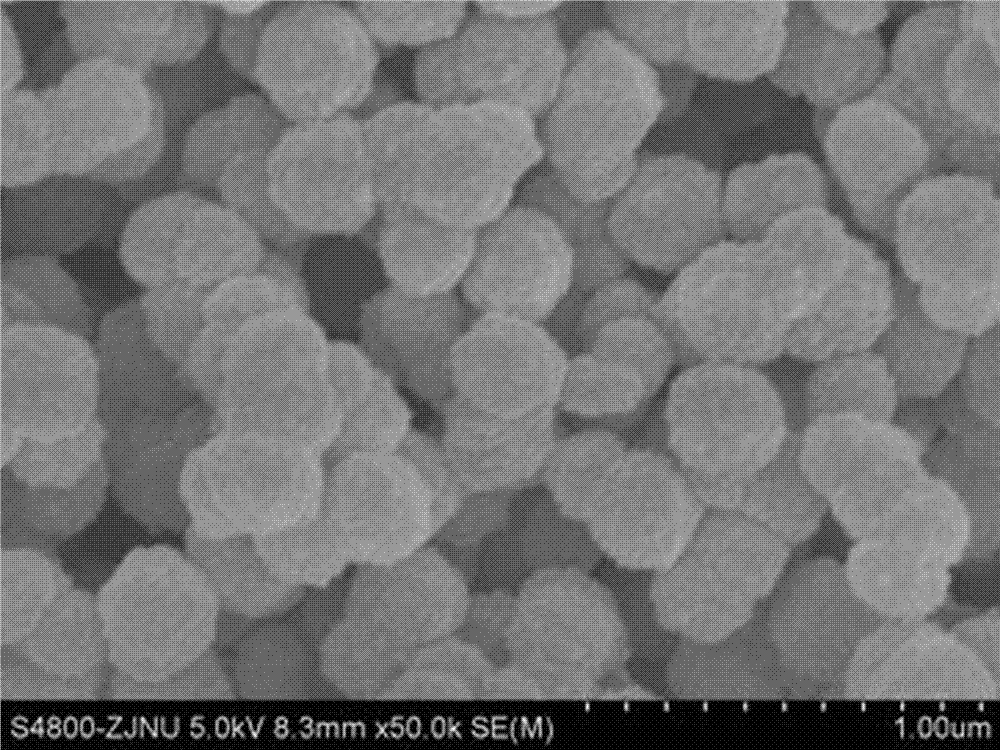

[0071] A preparation of mesoporous SiO 2 The method for / CdS composite nanosphere, its step is:

[0072] (1) Add 20 g of propyl orthosilicate, 8.0 g of octadecyltrimethoxysilane, and 20 g of ammonia water (25%-28% in mass concentration) into 100 ml of propanol, and stir to obtain a milky mixture. The resulting milky solution was sealed, the temperature was controlled at 30 ° C, and the reaction was carried out for 6 hours. The product was obtained by centrifugation, and the product was washed three times with absolute ethanol to obtain SiO 2 nanospheres;

[0073] (2) Take the above SiO 212g nanospheres, dispersed in 100ml ethylene glycol solution, add 40g hydrazine hydrate (mass concentration 85%), 1.7g cadmium chloride, 1.0g thiourea; react the solution at 50°C for 12 hours, and centrifuge SiO 2 / CdS composite nanosphere;

[0074] (3) The resulting SiO 2 / CdS composite nanospheres were calcined at 700 °C for 2 hours to obtain mesoporous SiO 2 / CdO composite nanospheres;...

Embodiment 3

[0082] A preparation of mesoporous SiO 2 The method for / CdS composite nanosphere, its step is:

[0083] (1) Add 10g of butyl orthosilicate, 5g of octadecyltrimethoxysilane, and 40g of ammonia water (25%-28% in mass concentration) into 100ml of ethylene glycol, and stir to obtain a milky mixture. The resulting milky solution was sealed, the temperature was controlled at 50 ° C, and the reaction was carried out for 12 hours. The product was obtained by centrifugation, and the product was washed three times with absolute ethanol to obtain SiO 2 nanospheres;

[0084] (2) Take the above SiO 2 10g nanospheres, dispersed in 100 ml ethanol solution, add 10g hydrazine hydrate (mass concentration 85%), 2.7g cadmium sulfate, 1.4g thiourea; react the solution at 60°C for 8 hours, and obtain SiO after centrifugation 2 / CdS composite nanosphere;

[0085] (3) The resulting SiO 2 / CdS composite nanospheres were calcined at 600 °C for 4 hours to obtain mesoporous SiO 2 / CdO composite nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com