Capacitor shaping and packaging machine

A packaging machine and capacitor technology, used in packaging, packaging capacitor devices, transportation and packaging, etc., can solve the problems of irregular capacitor leads, no integrated action, and inconsistent lengths.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

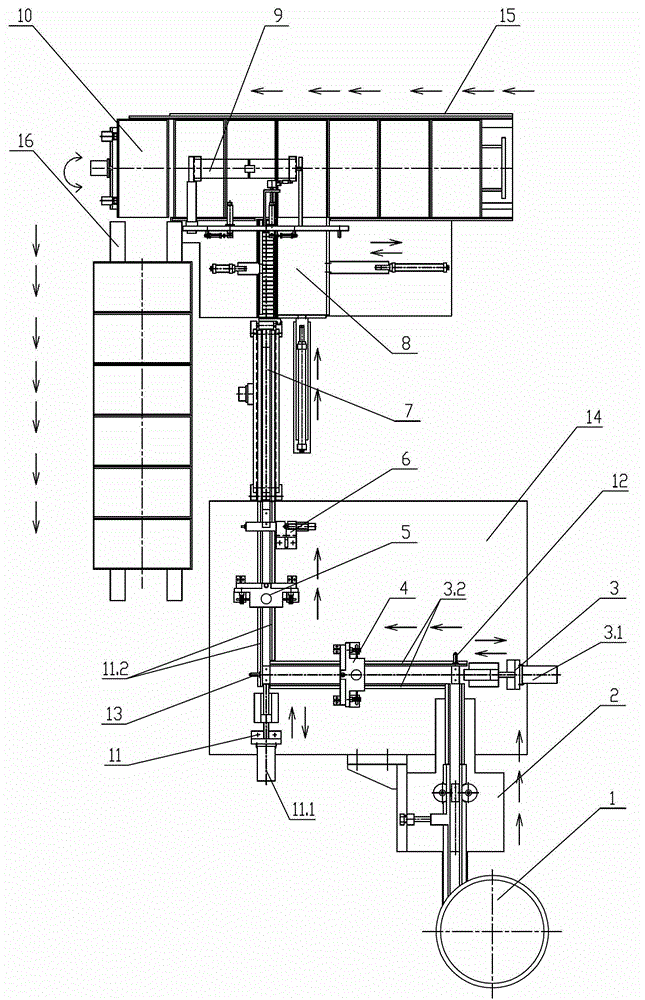

[0042] The present invention will be further described below with reference to the specific drawings and embodiments.

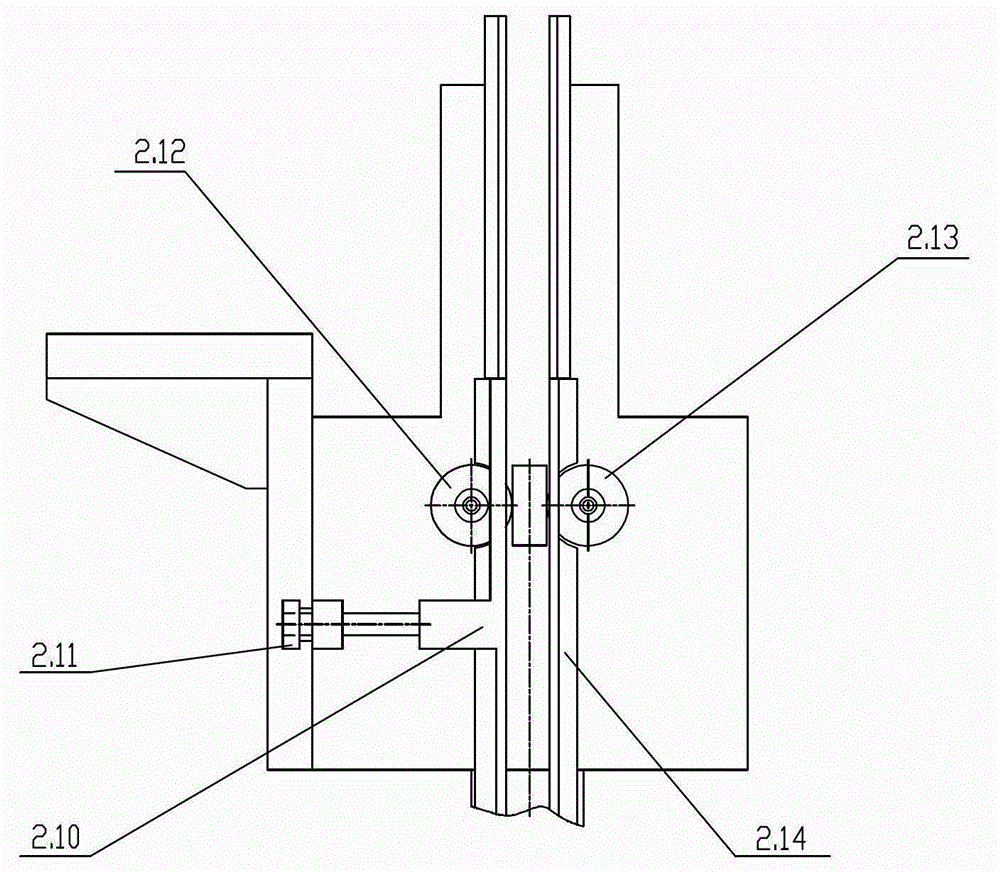

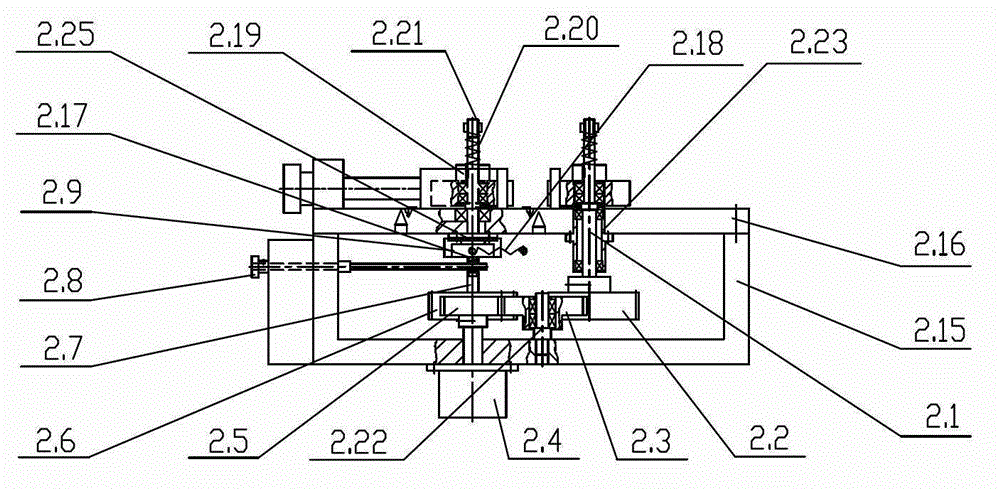

[0043] As shown in the figure, the capacitance shaping and packaging machine of the present invention is mainly composed of a vibrating plate 1, a transmission mechanism 2, a longitudinal feeding mechanism 3, a longitudinal shaping mechanism 4, a transverse shaping mechanism 5, a cutting mechanism 6, a conveying mechanism 7, and an array capacitor Mechanism 8, push capacitor box mechanism 9, transfer capacitor box mechanism 10, laterally push material mechanism 11, first sensor 12, second sensor 13, mounting frame 14, frame 15 and capacitor box output track 16 and other parts.

[0044] The vibrating plate 1 is used to realize the automatic feeding of the capacitor, and the capacitor is transported to the transmission mechanism 2 through the vibrating plate 1; The first sensor 12 is arranged at the entrance of the capacitive conveying channel of the longitudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com