Auxiliary braking system of centrifugal hydraulic light vehicle

A vehicle auxiliary and braking system technology, applied in the direction of brakes, vehicle components, brake transmission devices, etc., can solve the problems of easy heat decay, limited braking torque, short service life, etc., to achieve high system reliability, safety, The effect of mature manufacturing process and high service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

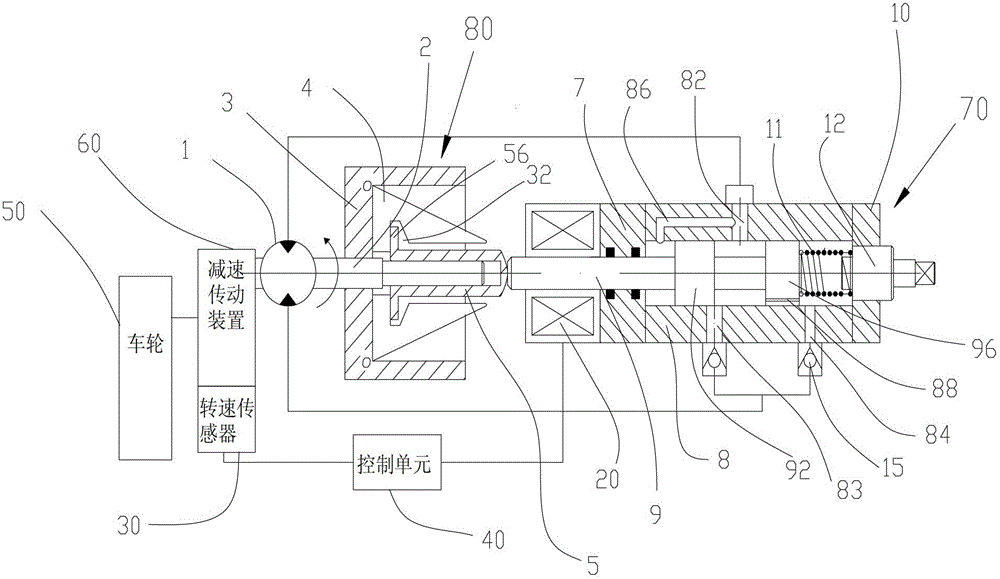

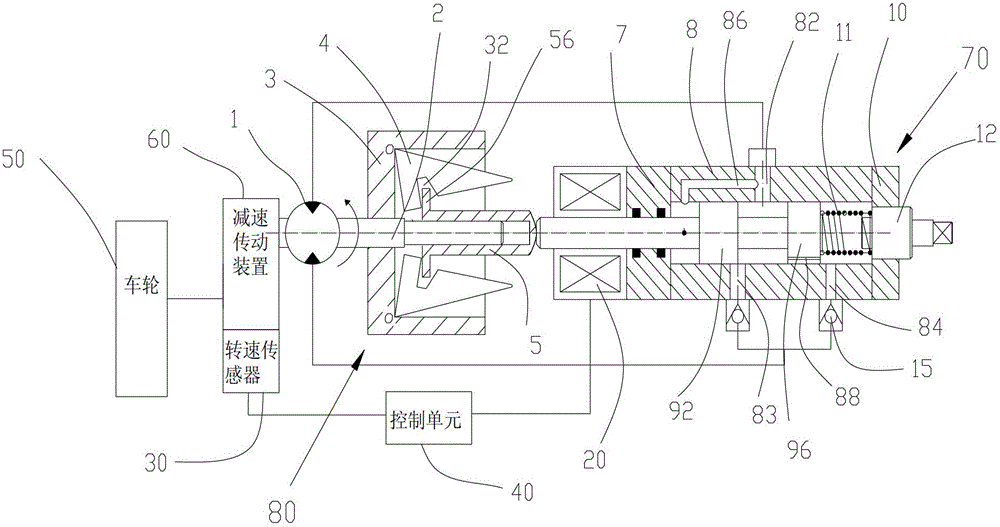

[0024] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further described:

[0025] See figure 1 , the present invention relates to a centrifugal hydraulic light vehicle auxiliary braking system, and its preferred embodiment includes a reduction transmission device 60, a rotational speed sensor 30, a hydraulic motor 1, a control unit 40, an electromagnetic coil 20, a centrifugal device 80 and a flow control valve 70. The hydraulic motor 1 is connected to the reduction transmission device 60, and the reduction transmission device 60 is connected to the wheel 50. The rotational speed sensor 30 is installed on the reduction transmission device 60 to detect the rotational speed, and is connected to the control unit 40 to send the detected rotational speed to the control unit 40 , the control unit 40 is connected with the electromagnetic coil 20 to adjust the current of the electromagnetic coil 20 according to the rotational spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com