Finishing method for straightening small and medium-sized angle steel double-line long ruler

A small and medium-sized, angle steel technology, applied in metal processing and other directions, can solve problems such as difficulty in handling the tail, angle steel production and economic impact, errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

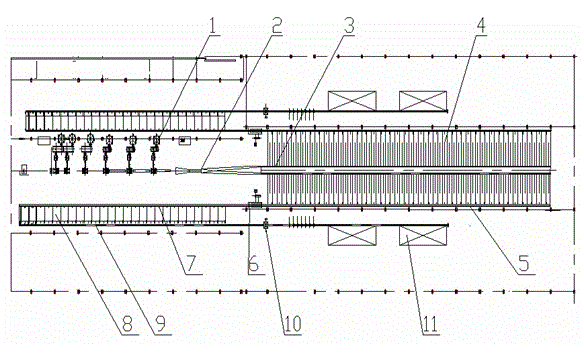

[0008] Take our company's production line rolling mill as an example of Φ550×1 blanking and Φ450 / Φ420×10 continuous rolling production line. In order to match the speed of the rolling mill, two identical finishing lines are used, the rolling speed is selected as 5-7m / s, and the straightening speed is selected as 3-4 m / s. The size of the walking cooling bed is 108m×12m, the straightening machine is Φ450 ten-roller type, the size of the cooling bed is 108m×5m, and the shearing capacity of the shearing machine is 400t.

[0009] After the continuous rolling finishing mill 1, a branching roller table 2 is set before conveying the finished product, so that the finished angle steel enters two finishing lines. Pneumatic reversing guide plates are set above the branching roller table 2, so that the finished angle steel enters two cooling beds 4 through the input roller table 3 at intervals. The cooling bed 4 steel feeding is the lifting skirt type, the cooling bed 4 steel moving is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com