Ethylene oxide preheating, sterilization and resolution integrated cabinet and sterilizing method

An integrated technology of ethylene oxide, which is applied in the field of ethylene oxide preheating, sterilization and analysis integrated cabinets and sterilization operations, can solve the problems of increased verification performance cycle, increased daily use cost, and increased plant construction area, etc. Achieve the effect of reducing the construction area of the plant, reducing the cost of daily use, and reducing the number of staff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

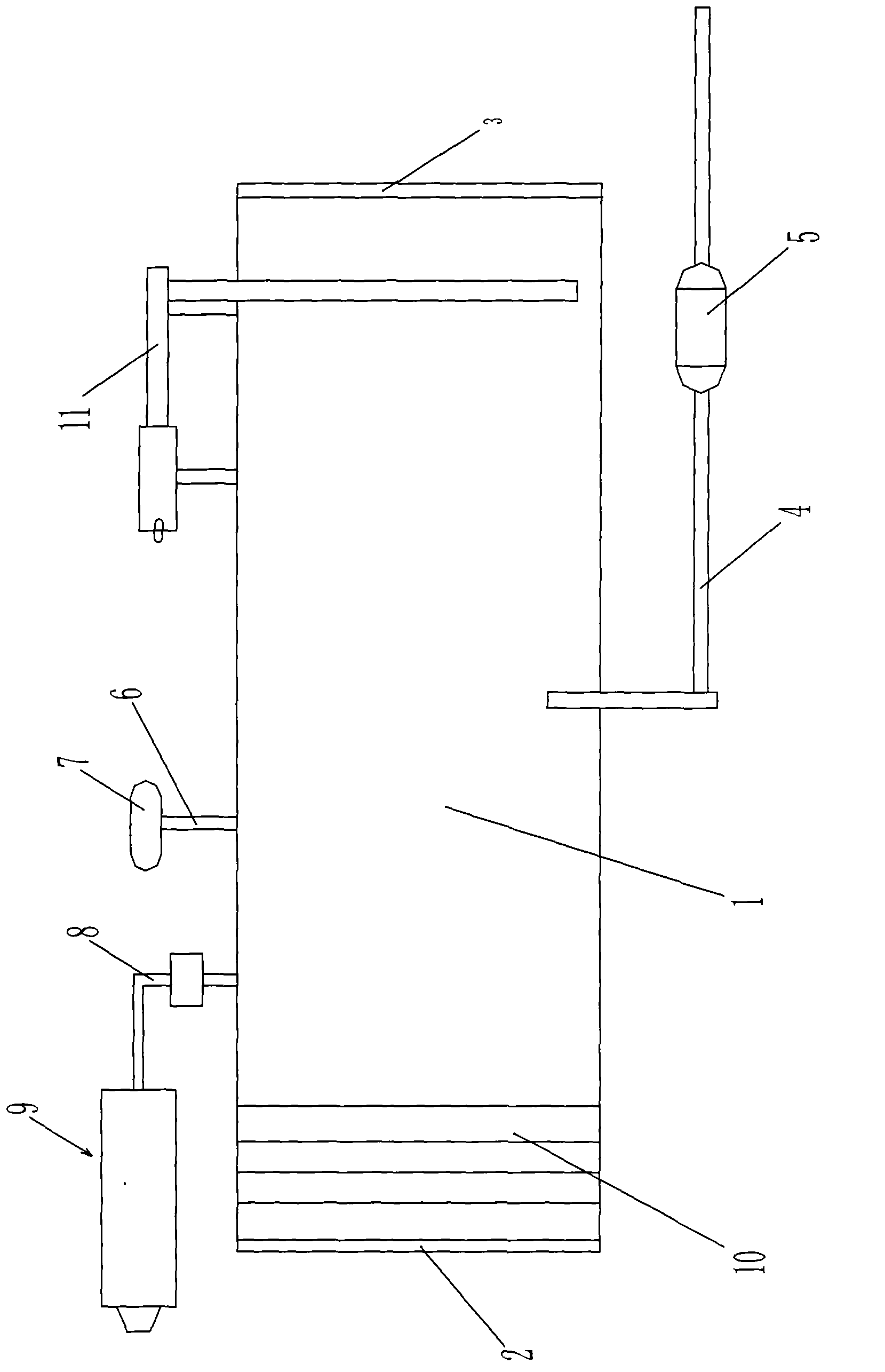

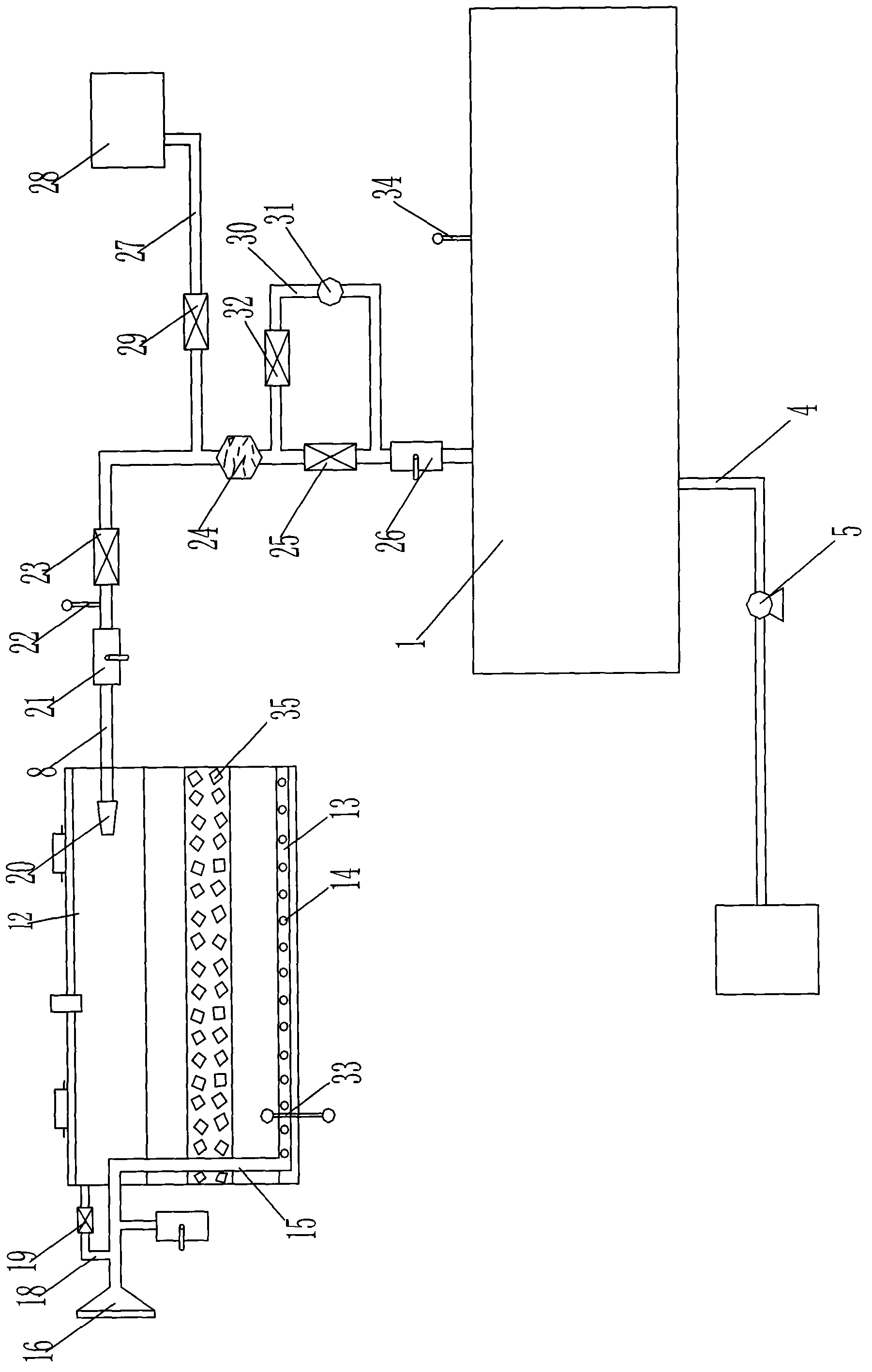

[0033] The sterilization operation method of the ethylene oxide preheating sterilization analysis integrated cabinet of the present invention comprises the following steps:

[0034] A) Pack the articles to be sterilized in paper packing boxes, open the front sealed door 2 of the preheating, sterilization, and analysis integrated cabinet, and put the packing box into the cabinet body 1 of the preheating, sterilization, and analysis integrated cabinet , and then close the front airtight door 2 of the integrated cabinet for preheating, sterilization and analysis;

[0035] B) Utilize the heating water jacket 10 of the preheating, sterilization and analysis integrated cabinet to heat the inside of the cabinet 1, start the vacuum pump 5 at the same time, and evacuate the inside of the cabinet 1 through the vacuum pumping pipeline 4, so as to remove the cold air in the cabinet 1 The body is drawn out, and after vacuuming to an absolute pressure of 30kpa-90kpa, stop vacuuming;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com