Automatic feeding trough

A feeding trough and automatic technology, applied in animal feeding devices, applications, animal husbandry, etc., can solve the problems of inconspicuous feed shifting effect, affecting the balance of live pigs, and uneven feeding of feeding basins, etc., and is easy to implement , Simple structure, smooth discharge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

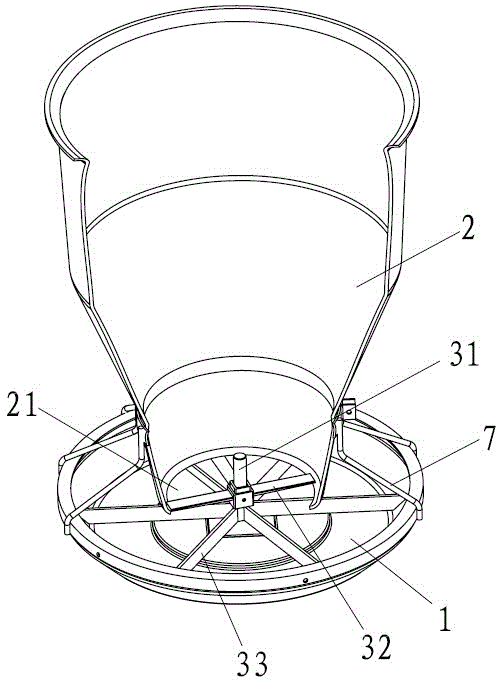

[0036] Embodiment 1: as figure 1 As shown, an automatic feeding trough includes a trough 1 and a barrel 2 fixedly connected to the top of the trough 1 through a fixing frame 7 .

[0037] The middle part of the material trough 1 is rotatably connected with a rotating shaft 31. A rotating arm 32 close to the discharge port 21 and extending outward along the middle part of the discharging port 21 is installed on the rotating shaft 31. The part below the rotating arm 31 is installed on the rotating shaft 31. There is a driving lever 33 for driving the rotating arm 32 to rotate through the rotating shaft 31 .

[0038] When in use, the live pig will hit the driving lever 33, so that the driving lever 33 drives the rotating arm 31 to swing, thereby realizing automatic feeding.

Embodiment 2

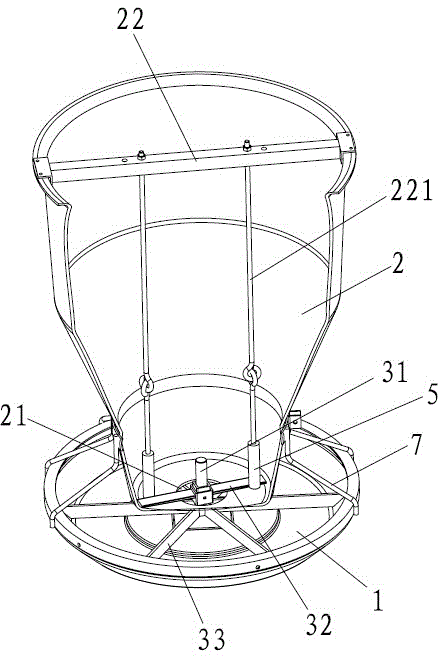

[0039] Embodiment 2: as figure 2 As shown, an automatic feeding trough includes a trough 1 and a barrel 2 fixedly connected to the top of the trough 1 through a fixing frame 7; the bottom surface of the barrel 2 is provided with a discharge port 21.

[0040] The middle part of the material trough 1 is rotatably connected with a rotating shaft 31. A rotating arm 32 close to the discharge port 21 and extending outward along the middle part of the discharging port 21 is installed on the rotating shaft 31. The part below the rotating arm 31 is installed on the rotating shaft 31. There is a driving lever 33 for driving the rotating arm 32 to rotate through the rotating shaft 31 .

[0041] The rotating arm 31 is located above the bottom surface of the material barrel 2, and is close to the bottom surface of the material barrel 2, and the free end of the rotating arm 31 extends outside the edge of the discharge port 21, and is close to the inner wall of the material barrel 2, so as ...

Embodiment 3

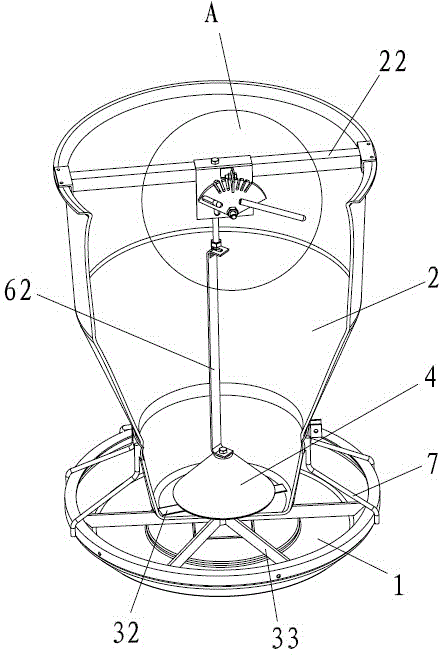

[0046] Embodiment 3: as Figure 3-5 As shown, an automatic feeding trough includes a trough 1 and a barrel 2 fixedly connected to the top of the trough 1 through a fixing frame 7; the bottom surface of the barrel 2 is provided with a discharge port 21.

[0047] The middle part of the material trough 1 is rotatably connected with a rotating shaft 31. A rotating arm 32 close to the discharge port 21 and extending outward along the middle part of the discharging port 21 is installed on the rotating shaft 31. The part below the rotating arm 31 is installed on the rotating shaft 31. There is a driving lever 33 for driving the rotating arm 32 to rotate through the rotating shaft 31 .

[0048] The rotating arm 31 is located above the bottom surface of the material barrel 2, and is close to the bottom surface of the material barrel 2, and the free end of the rotating arm 31 extends outside the edge of the discharge port 21, and is close to the inner wall of the material barrel 2, so a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com