Process for producing synthetic liquid hydrocarbons and reactor for fischer-tropsch synthesis

一种反应器、液态烃的技术,应用在天然气化工,石油化工,煤化工领域,能够解决差产品质量、选择性低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

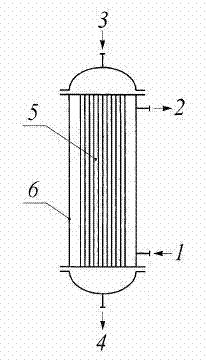

[0042] In a shell-and-tube reactor with a cylindrical tube with a total length of 6m, it includes two parts, the top and the bottom, and has a catalyst. The gas flow rate is delivered into the tube.

[0043] The 2.5 mm cobalt catalyst particles filled into the tube with a porosity of 0.4 were used. At the above gas hourly space velocity, the suitable catalytic temperature range of the catalyst was 210-217 °C. Water is fed into the housing at 210°C at a pressure of 19.1 bar (absolute).

[0044] The bottom has a diameter of 50nm and the top has a diameter of 25nm, a ratio of 2:1.

[0045] The length of the top is 3m, the length of the bottom is 3m, the ratio is 1:1.

[0046] The pressure gradient is 0.6 bar / m at a conversion rate of 60% near the top outlet.

[0047] With a pressure gradient below 0.1 bar / m at the bottom inlet, the reaction temperature increased from 210°C to 217°C.

[0048] The conversion at the reactor outlet reaches 80% with an overall pressure difference ...

Embodiment 7

[0059] Examples 7 to 9 illustrate that the use of known processes results in liquid product overflow in the tube, making the reaction inevitably fail (Example 7); or far away from the appropriate temperature range, causing the reaction to be deactivated by the catalyst and terminate the reaction (Example 8); or part of the pipe overflows and deviates from the appropriate temperature range at the same time, forming conditions that are unfavorable to the performance of the catalyst, which increases the energy consumption of compressed gas in the process design (Example 9).

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com