Composite component

A technology for composite parts and structural parts, applied in the direction of vehicle parts, superstructure, superstructure sub-assembly, etc., can solve the problem of reducing the strength of composite parts, and achieve the effect of preventing corrosion, high hardness and strength, and improving protection ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

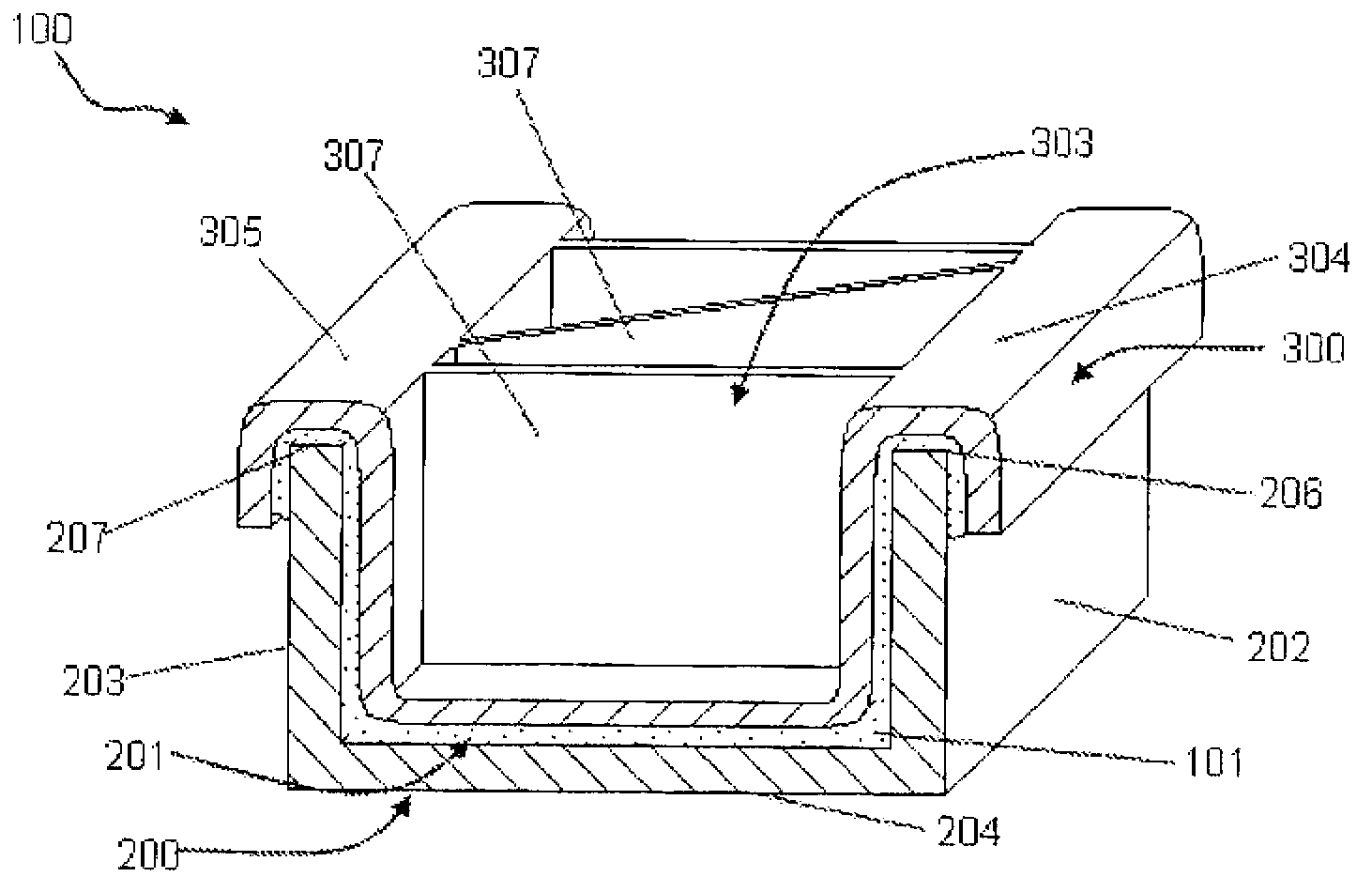

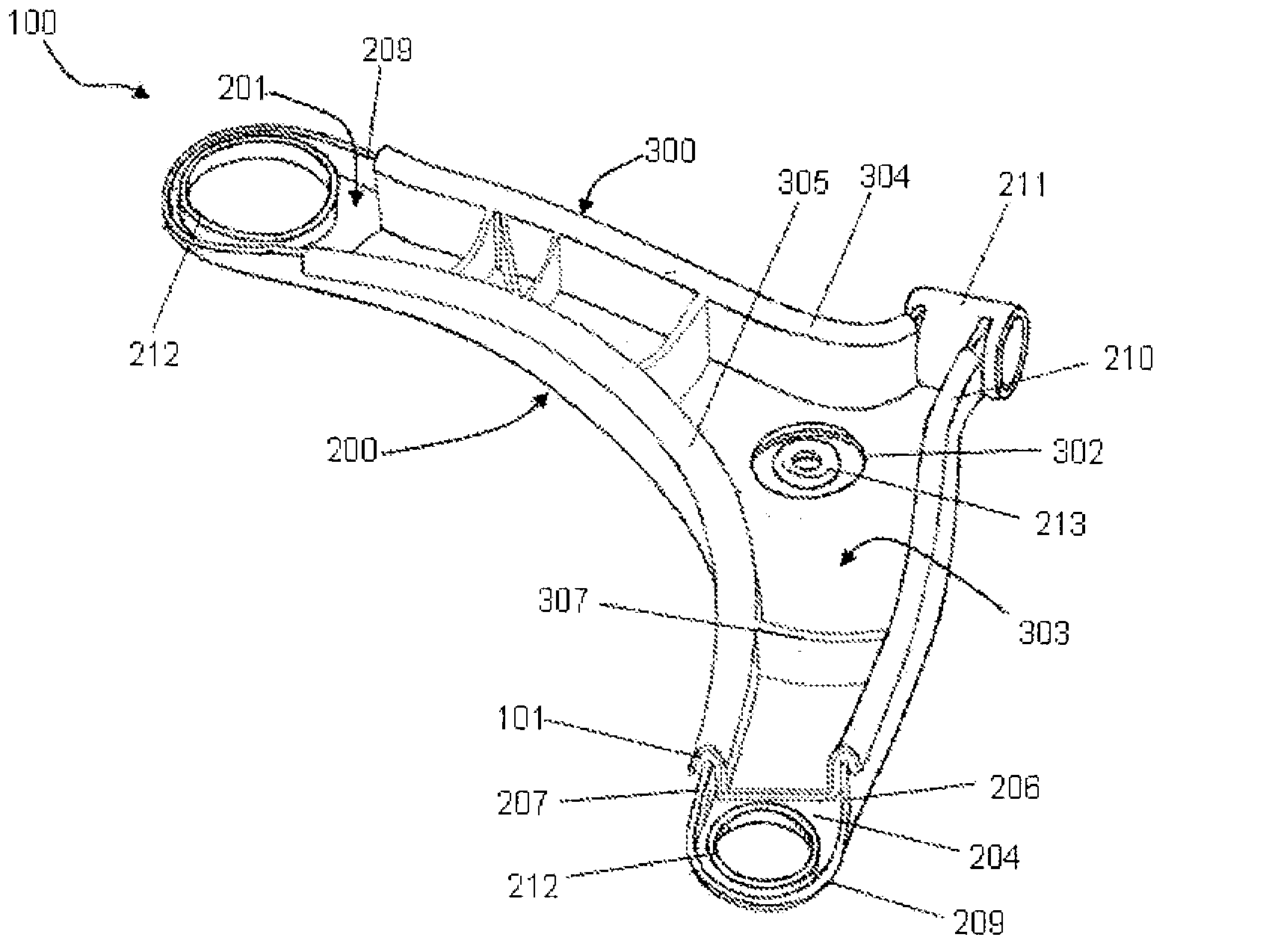

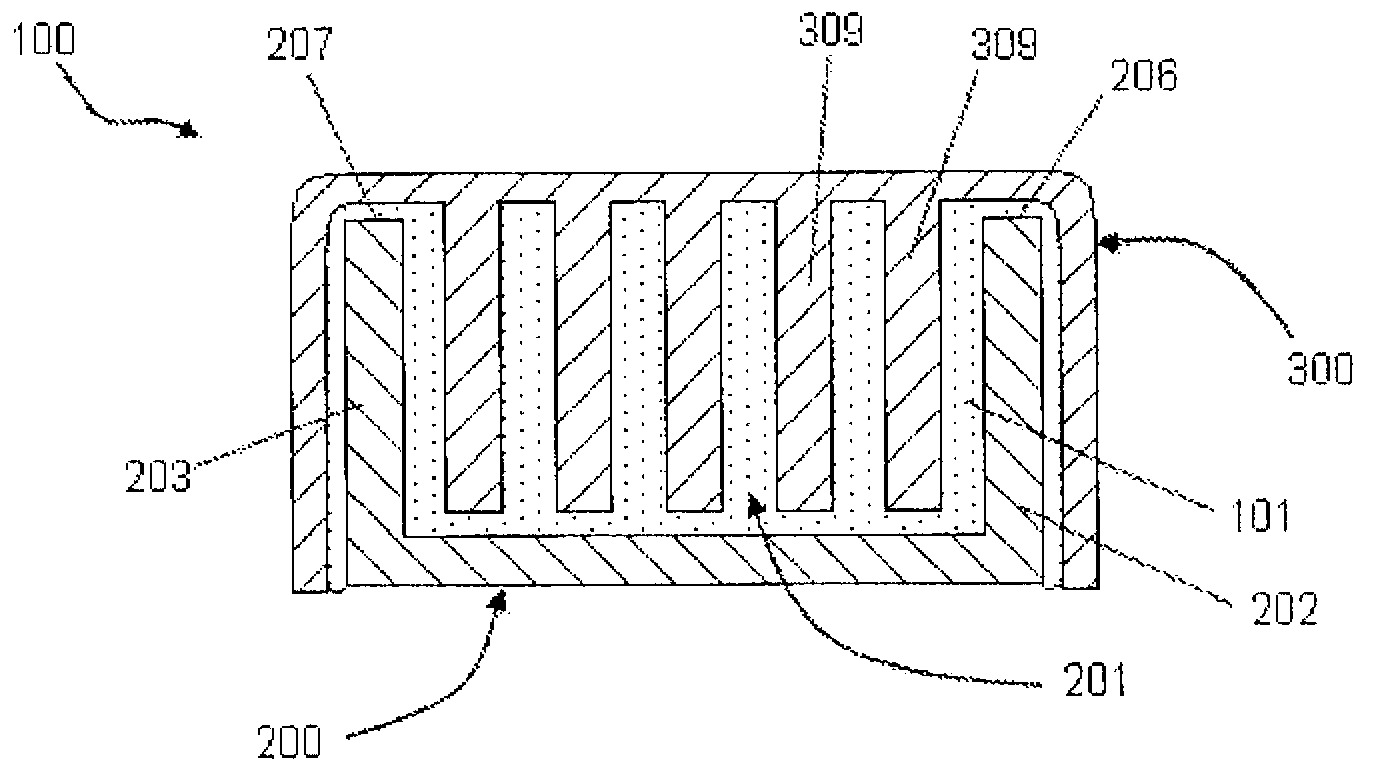

[0077] figure 1 A composite component 100 is shown having a channel shell 100 and a likewise channel-shaped structural component 300 placed in the channel shell 200 . In the shown sectional view, the case 200 has a U-shaped profile and includes a bottom 204 partially enclosing a space 201 , a first wall 202 and a second wall 203 . The structural part 300 arranged in the space 201 is arranged at a distance from the bottom 204 and from the walls 202 , 203 . A gap filled with the structural material 101 is provided between the structural member 300 and the case 200 . In the case of the present invention, this is a thermally expandable structural material 101 which, in the exemplary embodiment shown, is in an expanded state and which, on the one hand, provides for the fixation of the structural part 300 on the shell 200 and, on the other hand, in particular with The gap between the structural member 300 and the case 200 is filled in such a way that dirt and moisture cannot enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com