Magnetic resistance type multi-DOF (degree of freedom) magnetically-levitated planar motor

A planar motor, degree of freedom technology, applied in electrical components, holding devices with magnetic attraction or thrust, etc., can solve the problems of complex structure and low positioning accuracy of permanent magnet synchronous planar motors, and achieve light weight of the mover and less heat generation. , the effect of low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

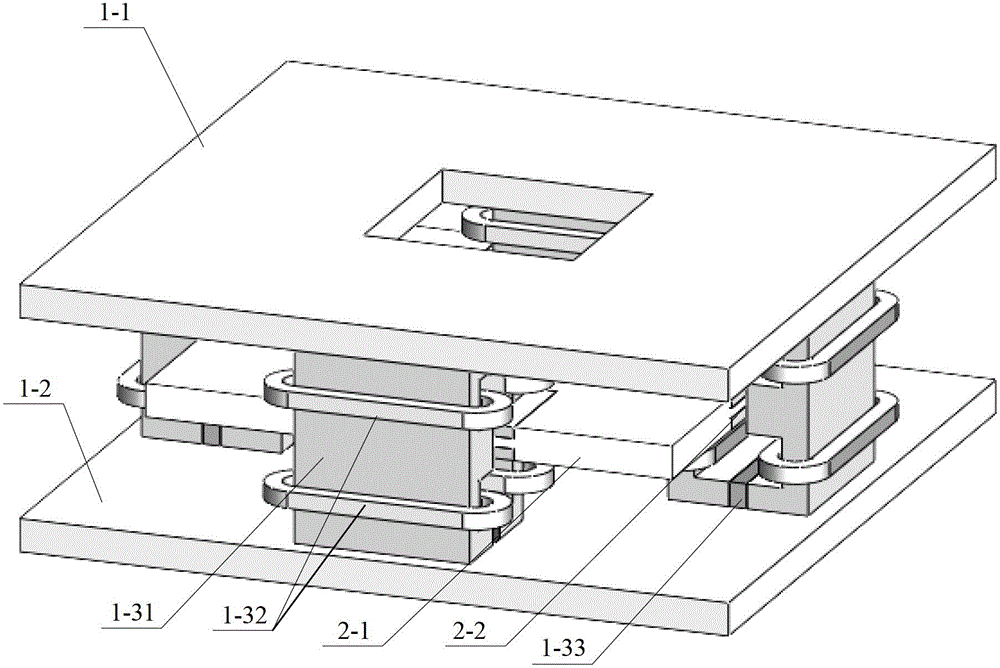

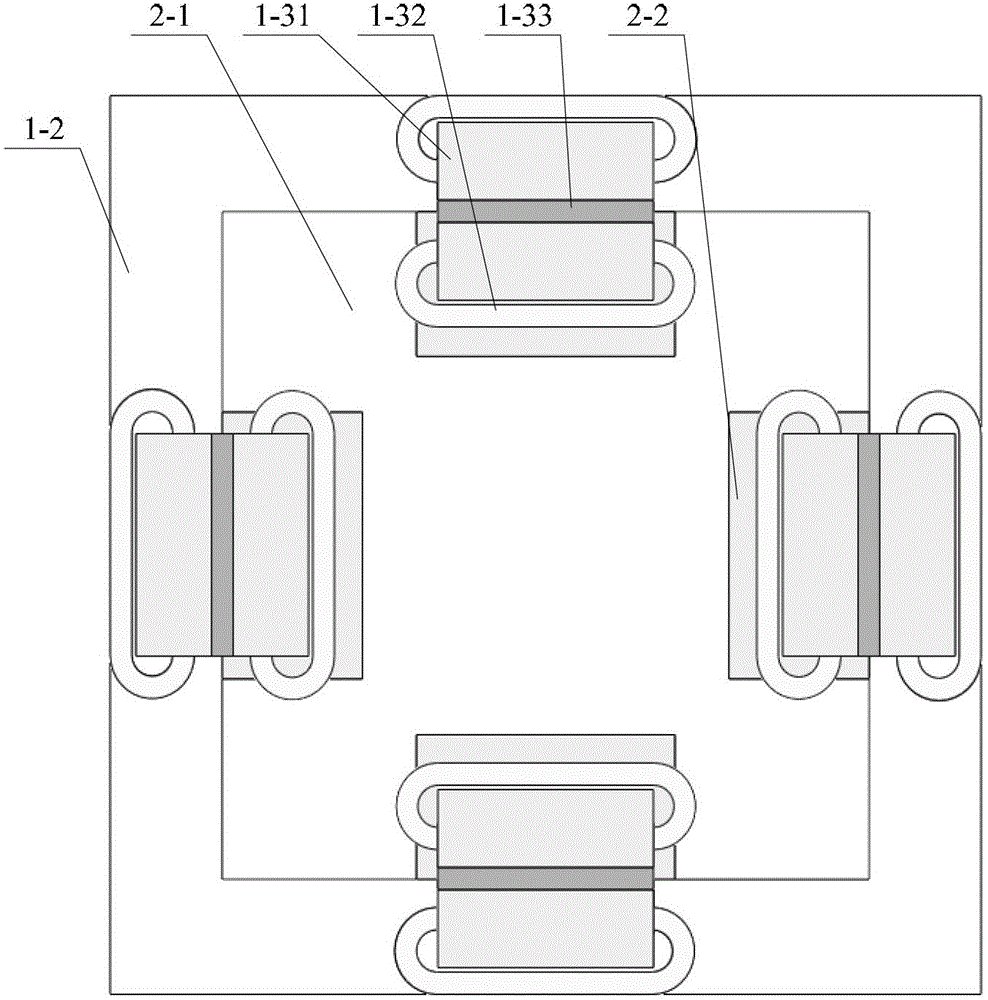

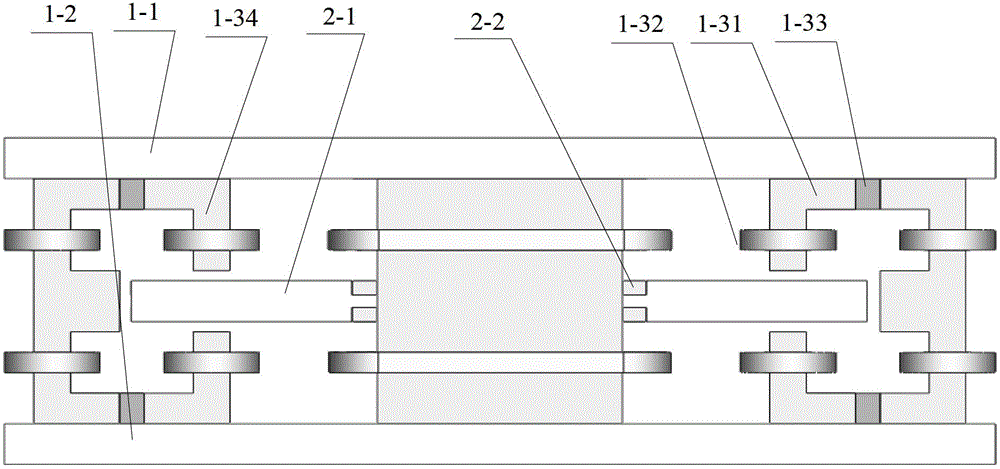

[0078] Specific implementation mode one: the following combination Figure 1 to Figure 4 Describe this embodiment, the reluctance type multi-degree-of-freedom magnetic levitation planar motor described in this embodiment includes a primary and a secondary, the primary includes an upper primary plate 1-1, a lower primary plate 1-2 and four armature units, each An armature unit is composed of an E-shaped armature core 1-31, an armature winding stage 1-32 and a primary permanent magnet 1-33.

[0079] The upper primary plate 1-1 and the lower primary plate 1-2 are rectangular flat plates, the upper primary plate 1-1 and the lower primary plate 1-2 are arranged relatively parallel, and four E-shaped armature cores 1-31 are clamped and fixed on the upper between the primary plate 1-1 and the lower primary plate 1-2, and the four E-shaped armature cores 1-31 are respectively located near the edges of each pair of opposite sides of the upper primary plate 1-1 and the lower primary pla...

specific Embodiment approach 2

[0085] Specific implementation mode two: the following combination Figure 5 to Figure 8 Describe this embodiment, the reluctance type multi-degree-of-freedom magnetic levitation planar motor described in this embodiment includes a primary and a secondary, the primary includes an upper primary plate 1-1, a lower primary plate 1-2 and six armature units, each An armature unit is composed of an E-shaped armature core 1-31, an armature winding stage 1-32 and a primary permanent magnet 1-33.

[0086] The upper primary plate 1-1 and the lower primary plate 1-2 are both rectangular flat plates, the upper primary plate 1-1 and the lower primary plate 1-2 are arranged relatively parallel, and six E-shaped armature cores 1-31 are clamped and fixed on the upper Between the primary plate 1-1 and the lower primary plate 1-2, four E-shaped armature cores 1-31 are evenly and symmetrically arranged on two pairs of opposite long sides of the upper primary plate 1-1 and the lower primary plate...

specific Embodiment approach 3

[0092] Specific implementation mode three: the following combination Figure 9 to Figure 13 Describe this embodiment, the reluctance type multi-degree-of-freedom magnetic levitation planar motor described in this embodiment includes a primary and a secondary, the primary includes an upper primary plate 1-1, a lower primary plate 1-2 and three armature units, each An armature unit is composed of an E-shaped armature core 1-31, an armature winding stage 1-32 and a primary permanent magnet 1-33.

[0093] The upper primary board 1-1 and the lower primary board 1-2 are hexagonal flat plates formed by connecting three equal-length long sides and three equal-length short sides alternately, and the upper primary board 1-1 and the lower primary board 1- 2 Relatively arranged in parallel, three E-shaped armature cores 1-31 are clamped and fixed between the upper primary plate 1-1 and the lower primary plate 1-2, and are respectively located on the upper primary plate 1-1 and the lower p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com