Interleaved parallel three-phase power factor correction circuit

A three-phase, parallel technology, applied in the direction of electrical components, high-efficiency power electronic conversion, sustainable manufacturing/processing, etc., can solve problems such as increased input current ripple, difficult filter design, and larger power supply volume, and achieves input Reduce current fluctuations, facilitate PCB layout and thermal design, and reduce interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

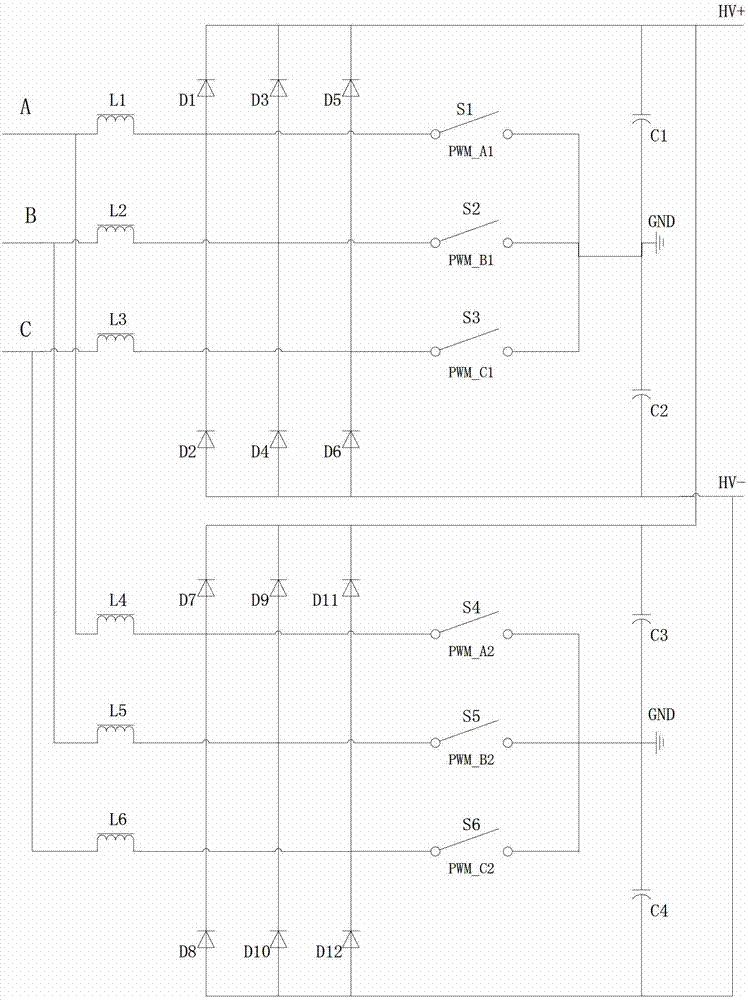

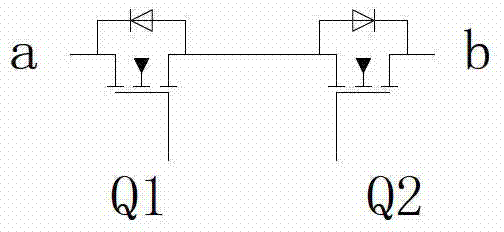

[0024] Reference Figure 1-5 , Interleaved parallel three-phase PFC circuit, which consists of two Vienna converters, the Vienna converter is a three-phase three-switch three-level PFC structure, the three-phase input of the first Vienna converter is connected to the second Vienna converter Three-phase input, the three-level output of the first Vienna converter is respectively connected to the three-level output of the second Vienna converter. Both the first Vienna converter and the second Vienna converter include three bidirectional switches. The switches are all turned on and off by the current of an independent inductor. The cycle start and end times of the three bidirectional switches of the first Vienna converter are the same, and the cycle of the three bidirectional switches of the second Vienna converter starts Same as the end time, the cycle start and end time of the three bidirectional switches of the first Vienna converter lead or lag the cycle start and end time of t...

Embodiment 2

[0036] Reference Figure 7 The difference between this embodiment and the first embodiment is that the bidirectional switch is composed of a rectifier bridge and a switch tube, and the output of the rectifier bridge and the switch tube are connected in parallel. The rest of the structure and function are the same as the first embodiment.

Embodiment 3

[0038] Reference Figure 8 The difference between this embodiment and the first embodiment is that the bidirectional switch is composed of a rectifier bridge and a switch tube, and the output of the rectifier bridge and the switch tube are connected in parallel. And instead of connecting the intermediate node of the inductor and the bidirectional switch to the intermediate node between the two diodes in series, the two ends of the switch tube of the bidirectional switch are connected between the two diodes in series. The rest of the structure and function are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com