Ultrasonic flaw detection auxiliary device inside air bottle

An auxiliary device, ultrasonic technology, applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc. It can solve the problems of small bottle mouth, detection, and difficult identification of ultrasonic echoes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment, further elaborate the present invention.

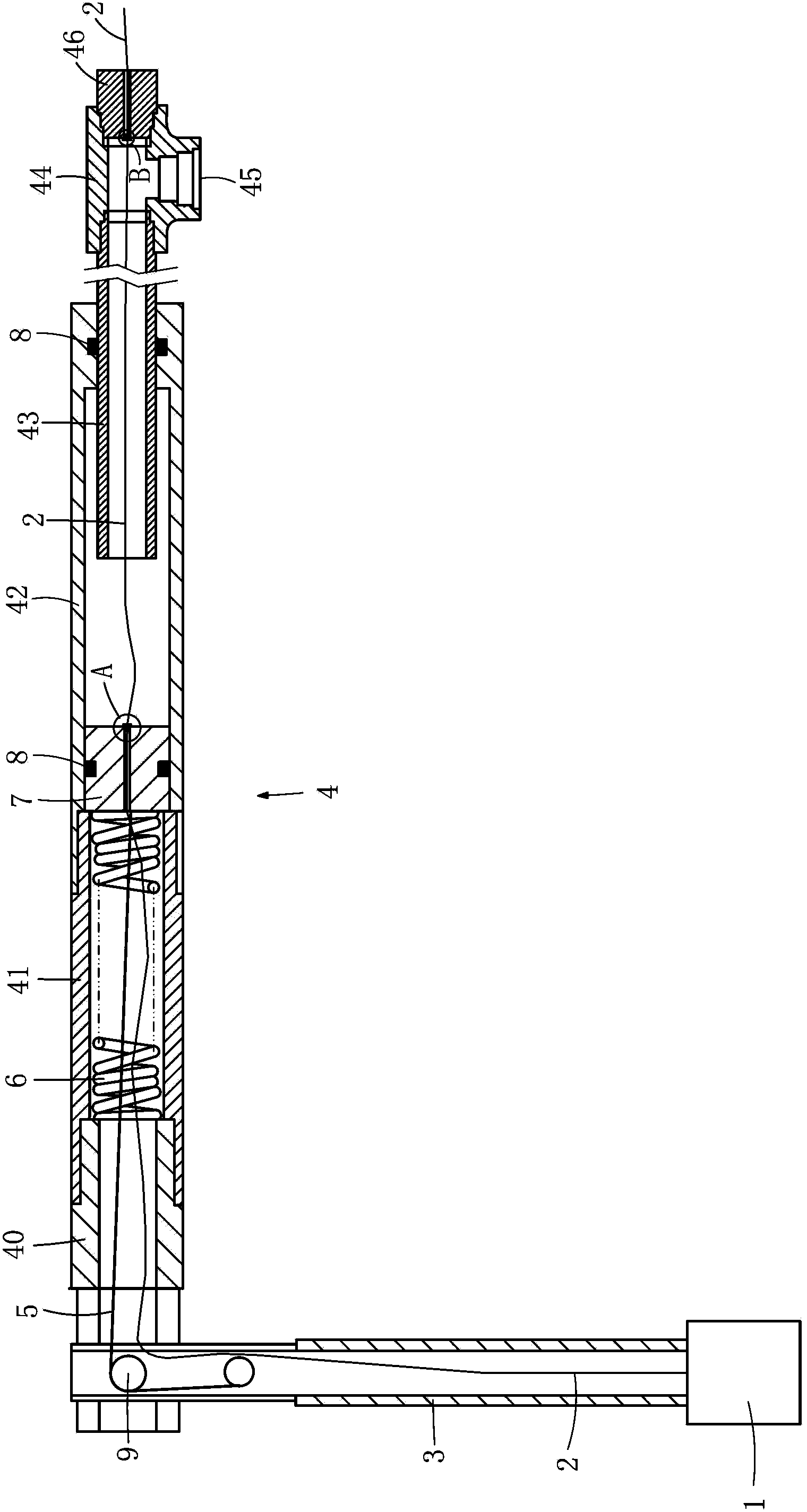

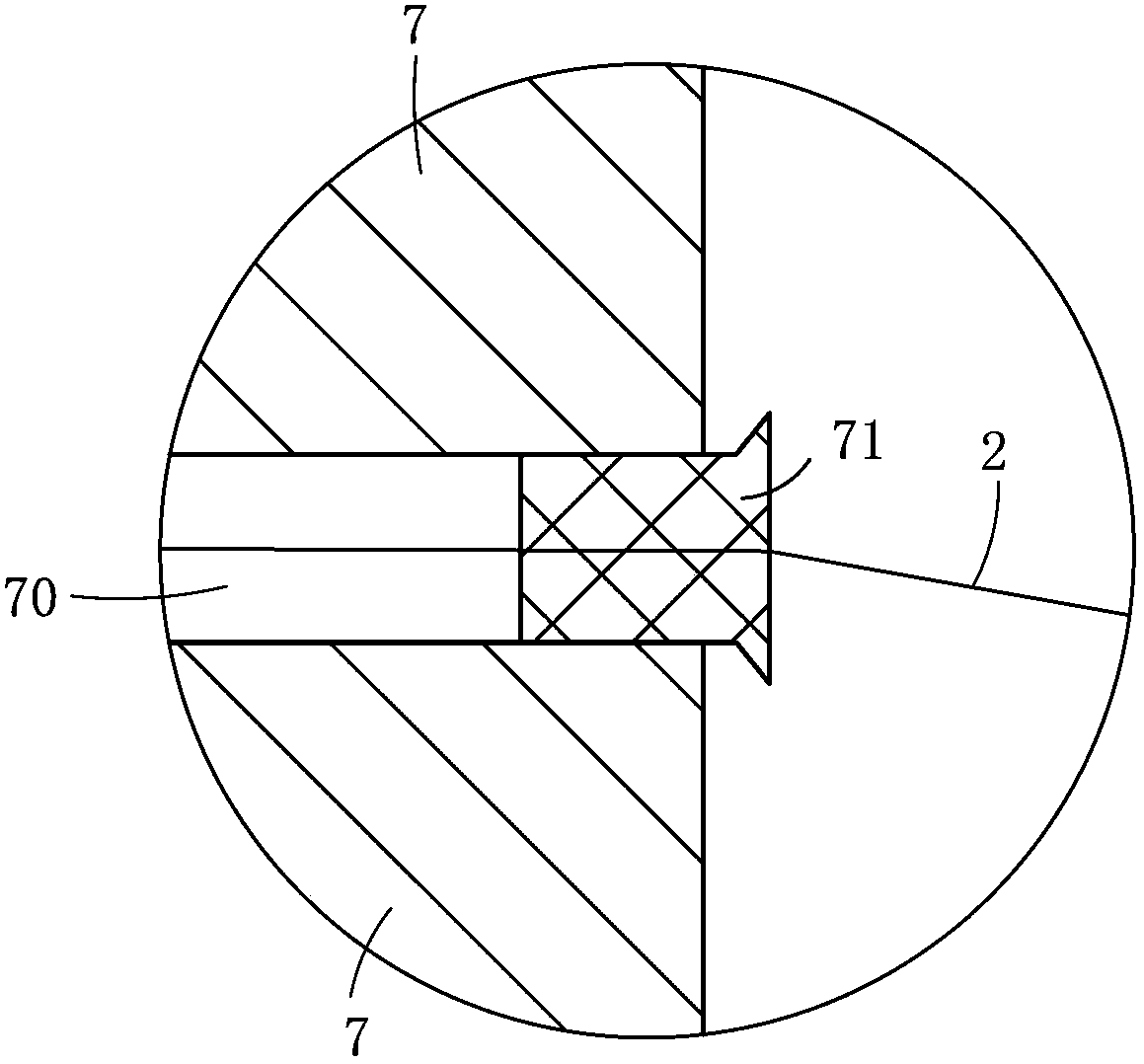

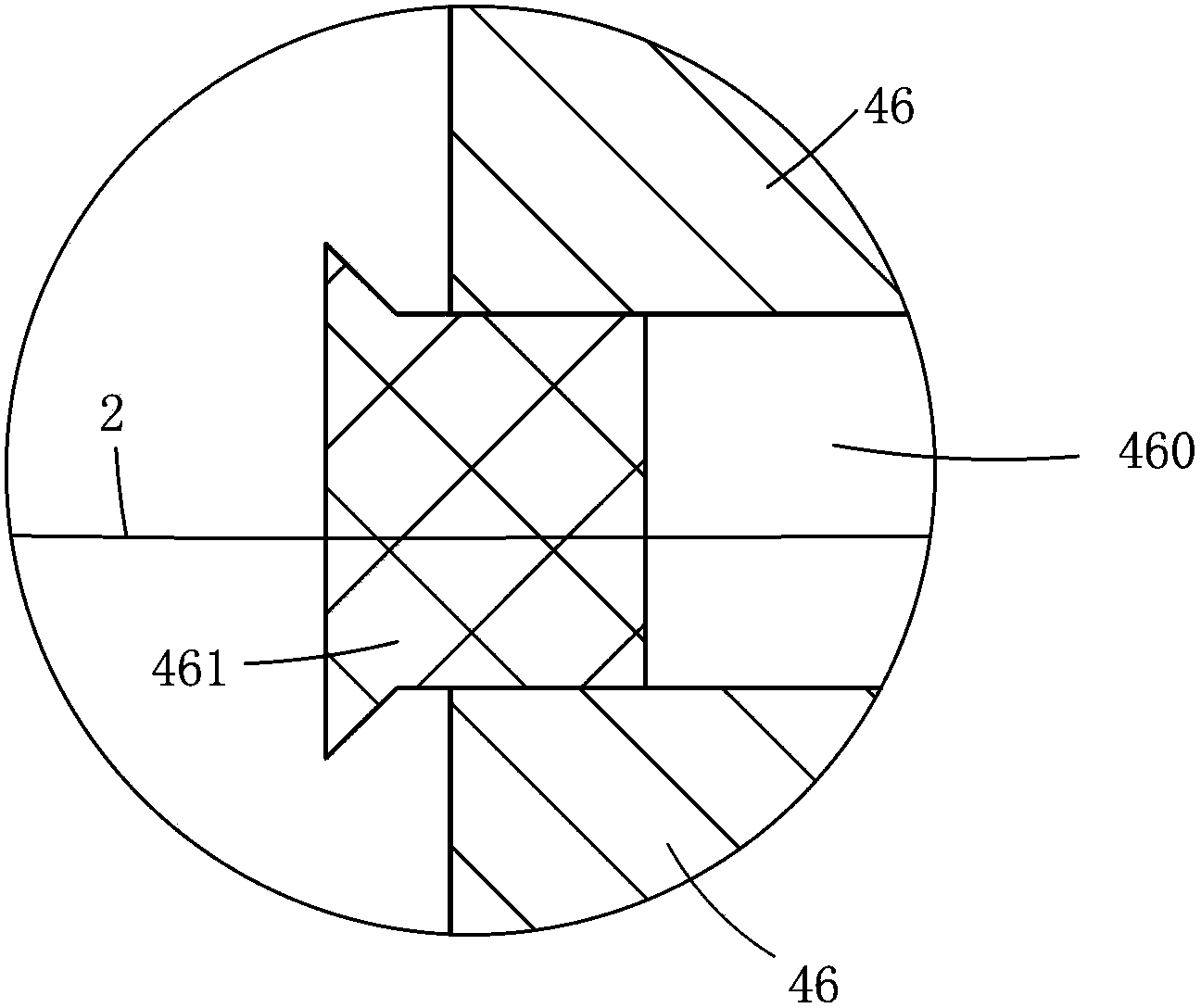

[0022] Such as figure 1 , figure 2 , image 3 and Figure 4 Commonly shown, an auxiliary device for ultrasonic flaw detection inside a gas cylinder, including a sleeve assembly 4, one end of the sleeve assembly 4 is hinged with an ultrasonic probe connector 3 through a hinge shaft 9, and an ultrasonic probe 1 is installed at one end of the ultrasonic probe connector 3 The other end of the sleeve assembly 4 is provided with a vent hole 45 communicating with the inner cavity of the sleeve assembly 4, the inner cavity of the sleeve assembly 4 is provided with a compression spring 6, and one end of the compression spring 6 is fixed on the sleeve assembly 4, The other end of the compression spring 6 is connected with a positioning block 7, and the positioning block 7 is slidably arranged in the inner cavity of the sleeve assembly 4. The positioning block 7 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com