Corrosive environment sensor and method for measuring corrosive environment

A technology of corrosive environment and measurement method, which is applied in the field of corrosive environment sensor and corrosive environment measurement, and can solve problems such as inability to be completely consistent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

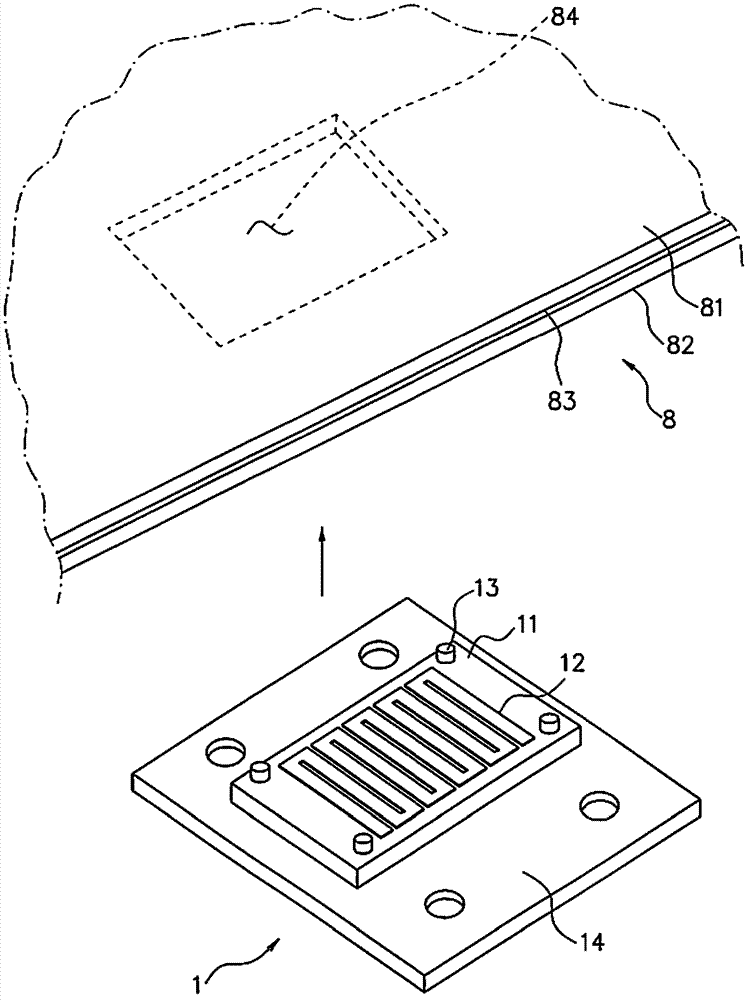

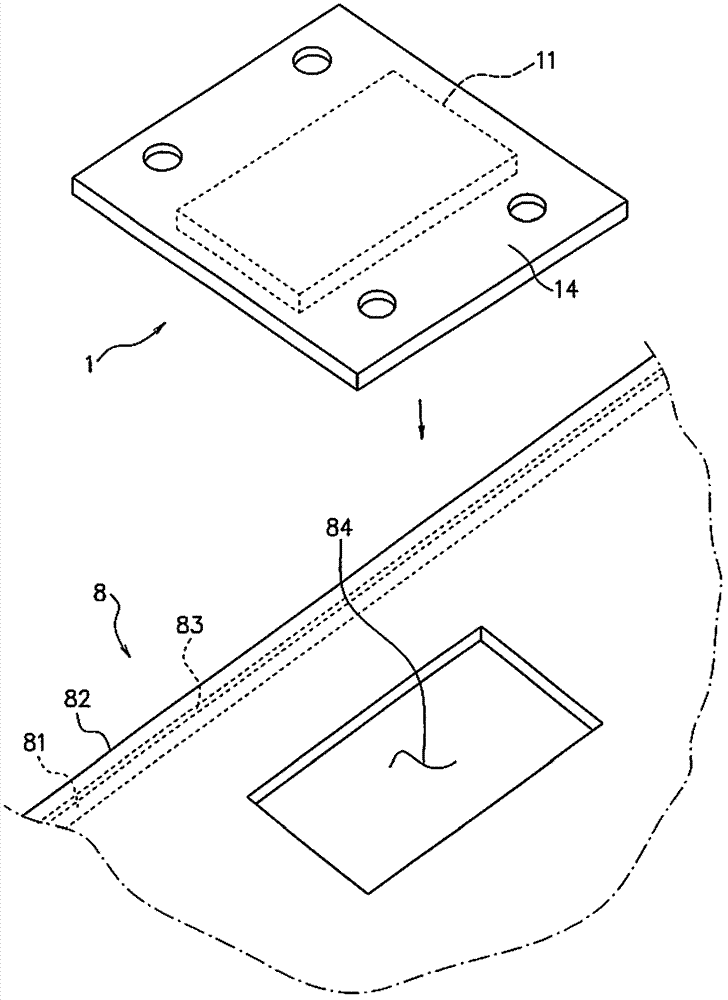

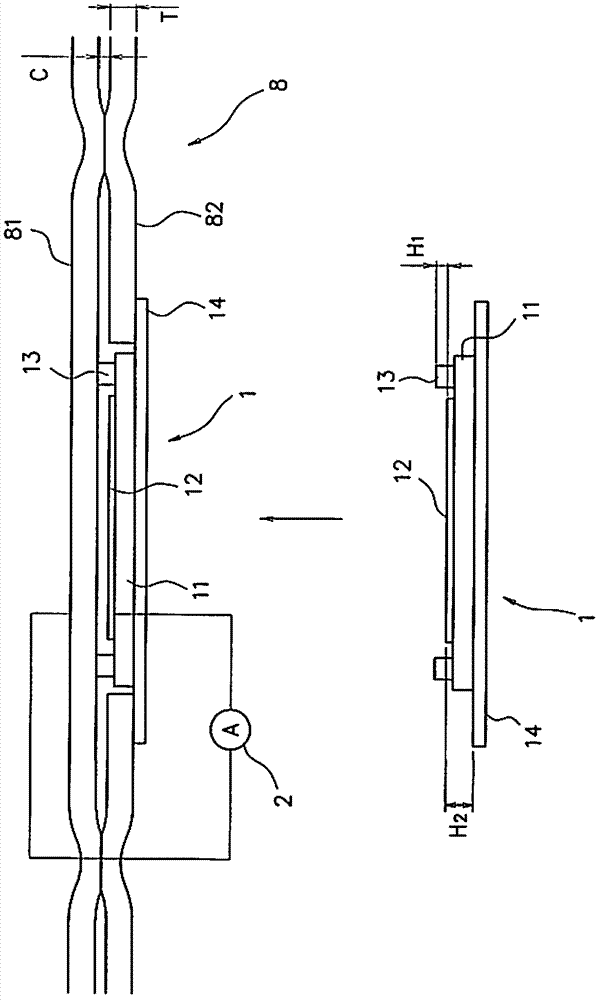

[0027] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. The corrosion environment sensor 1 according to the embodiment of the present invention can measure the corrosion environment of a gap between two members in which at least one member is a conductor. Among them, the “corrosive environment” is defined as the influence of the environment on the corrosion of structures and the like (corrosiveness of the environment). In the following description, as the measurement target, the structure 8 having the overlapping portion where the first member 81 and the second member 82 overlap is shown as an example. In addition, Figure 1 ~ Figure 3 The overlapping portion where the first member 81 and the second member 82 overlap are extracted and shown. In addition, the first member 81 is a conductor. For the first member 81, when there is no conductivity, scrape off the insulator layer, film (for example, paint, oxide film), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com