Anti-vibration mount

A technology of anti-vibration installation and installation holes, applied in the direction of non-rotational vibration suppression, etc., can solve the problem of the stability of the fixed connection, without considering the elastic body and other problems, and achieve the effect of improving durability and relaxing elastic force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

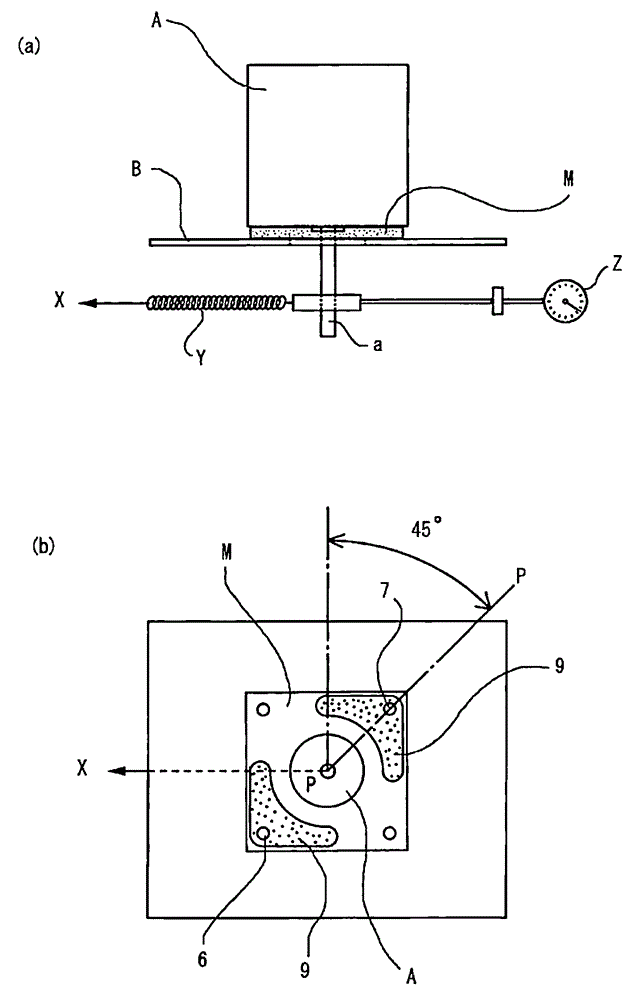

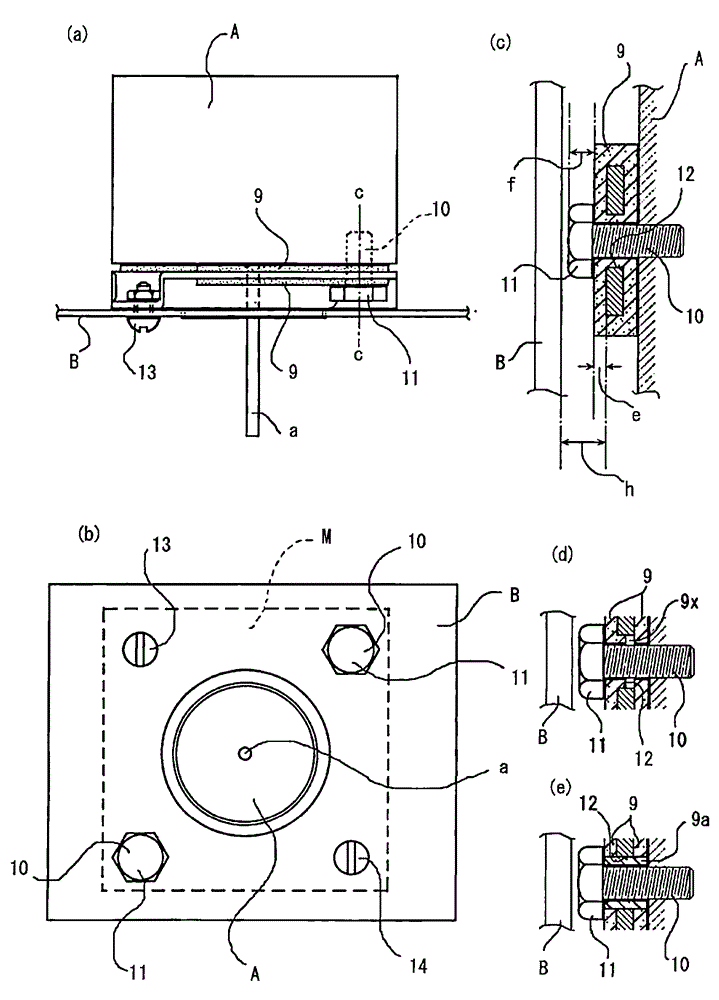

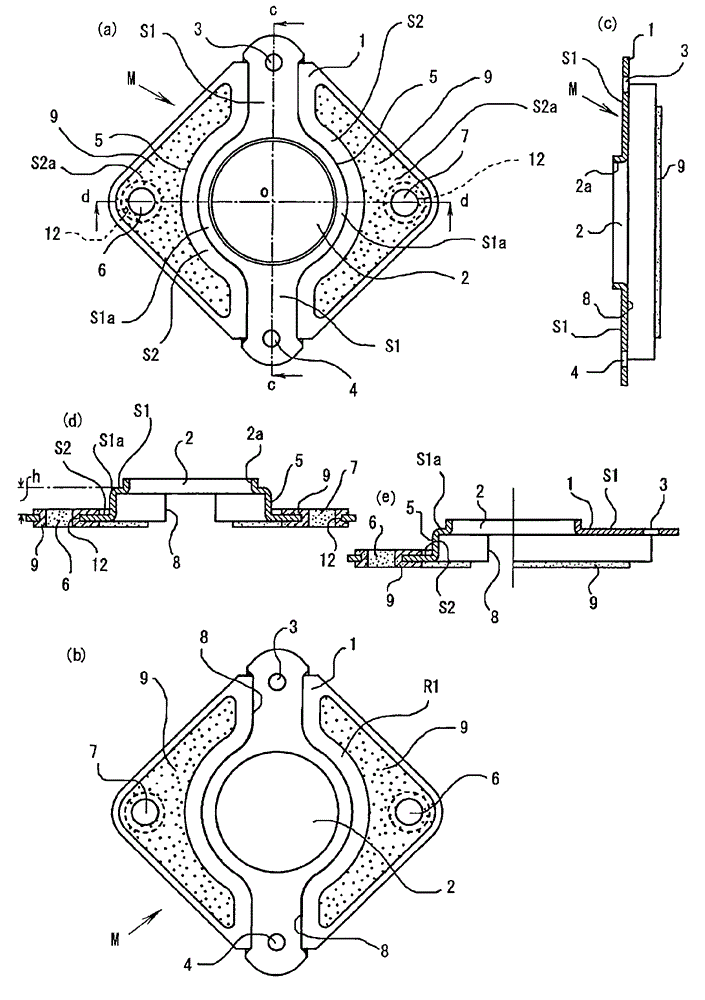

[0028] Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

[0029] [Example]

[0030] In the figure, 1 denotes a rigid plate made of a rigid material such as metal and rigid synthetic resin as the skeleton of the anti-vibration mounting member M, and has a central hole 2 in one direction. The upper and lower parts of the vertical direction are provided with high-level surfaces S1 of the mounting holes 3 and 4 as a contact surface with the mounting body B, and are provided with steps 5, 5 passing through the height h on the left and right with the center hole 2 as the center. The low surface S2 that expands in the left-right direction is provided with left and right mounting holes 6 and 7 sandwiching the center hole 2 to form a contact side with the vibrating member A on the back surface R1 side of the mounting holes 6 and 7. In addition, the above-mentioned hard board 1 can be formed in a square shape with a central hole 2 in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com