Piezoelectric pump and piezoelectric ceramics piece protection process

A technology of piezoelectric ceramic sheets and piezoelectric pumps, applied in piezoelectric/electrostrictive/magnetostrictive devices, pumps, circuits, etc., can solve problems such as low pressure and flow rate, easy burning, complex production process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in more detail below in conjunction with the accompanying drawings and specific embodiments.

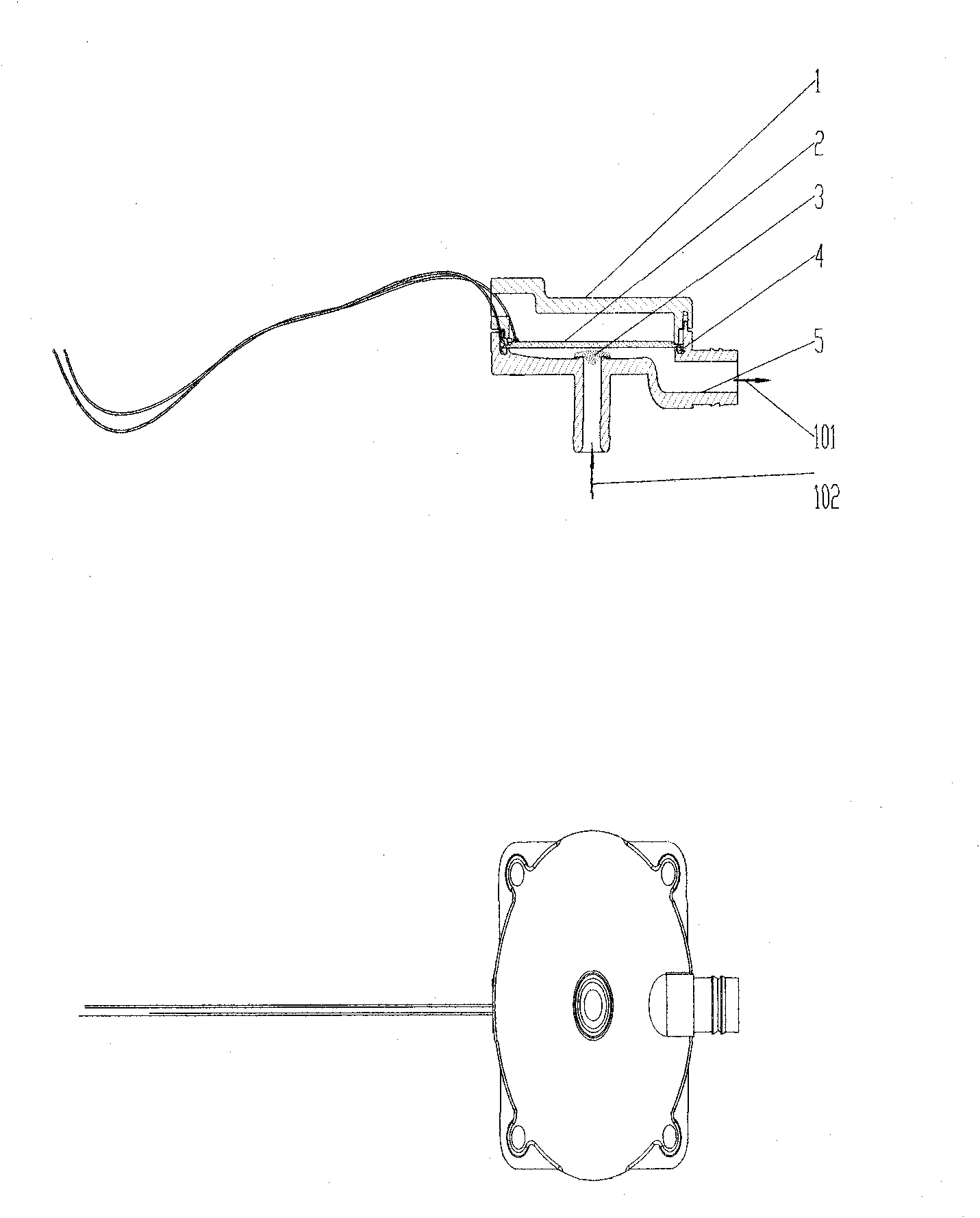

[0009] figure 1 It is an embodiment of the medium piezoelectric pump of the present invention. It consists of an upper shell (1), a transducer plate (2), a valve plate (3), a sealing ring (4) and a lower shell (5). After assembling the aforementioned parts , the upper shell (1) and the lower shell (5) are connected by screws or ultrasonically welded together to form a complete piezoelectric pump. The sealing ring (4) is installed near or at the maximum circumference of the transducer sheet (2), which is equivalent to the fulcrum of the lever leaning toward the maximum circumference, which is beneficial to effectively utilize the maximum amplitude of the transducer sheet (2).

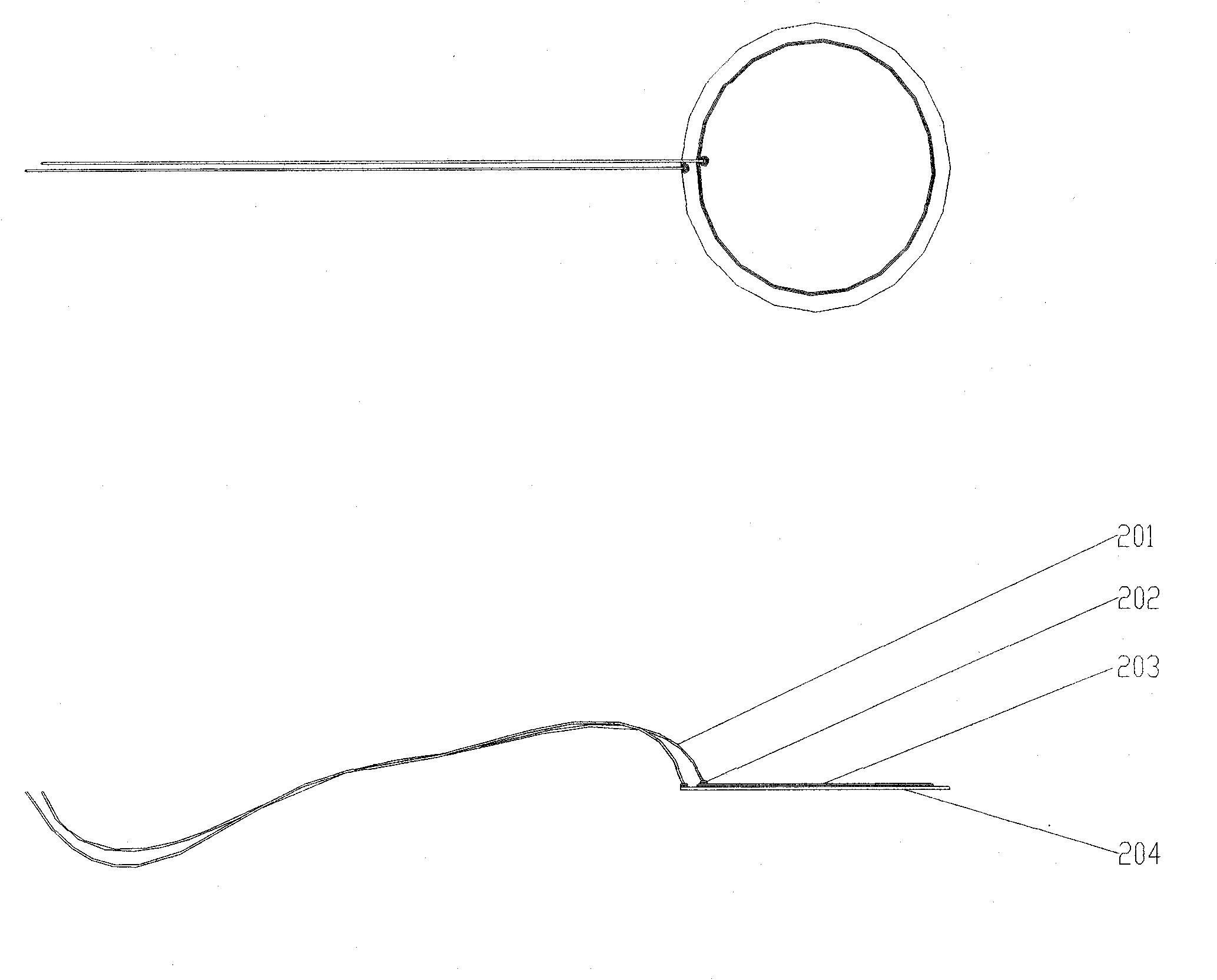

[0010] figure 2 It is an embodiment of the protection process of the piezoelectric ceramic sheet in the present invention: the surface of the solder joint (202)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com