Novel bridge inspection vehicle

A bridge maintenance vehicle, a new type of technology, applied in the direction of bridge maintenance, bridges, bridge parts, etc., can solve problems such as limited, large cantilever on both sides, complicated locks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

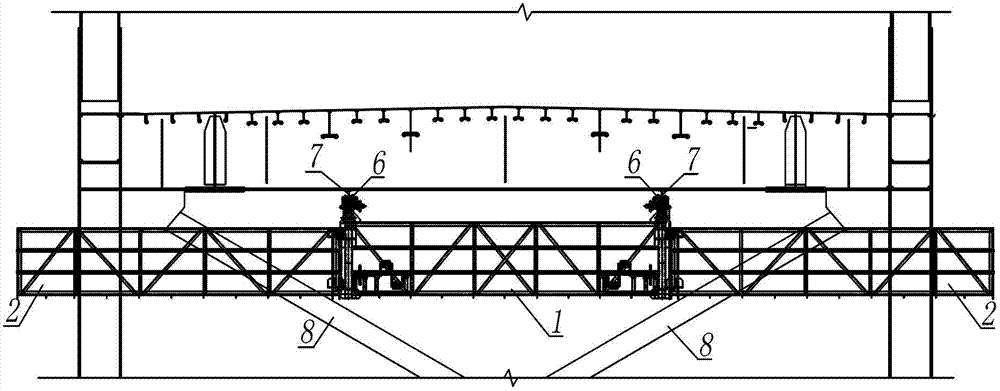

[0018] The vehicle body of the present invention is composed of a vehicle body 1 in the middle and cantilever additional vehicle bodies 2 on both sides, and is connected as a whole by a rotary hinge 3 and a fixed pin 4 . The top of the car body 1 is equipped with a wheel mechanism 6, suspended under the longitudinal track 7 of the bridge, and the opening and closing handle 5 is installed at the front or rear end of the rotating hinge 3 on both sides, and the other end is provided with a fixed pin jack 4, and the two sides are connected to each other. relative to the direction.

[0019] The present invention usually takes the form of figure 1 , 2 , The expansion mode shown in 3 walks longitudinally along the bridge. When encountering the horizontal connecting member 8 in the truss, turn the opening and closing handle 5, and the cantilever additional car body 2 on both sides will rotate horizontally through the rotating hinge 3 and overlap the front and rear of the car body, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com