Method for collecting and controlling cleaning particles of washing machine with self-cleaning function and washing machine

A control method and technology for washing machines, which are applied to control devices of washing machines, other washing machines, washing devices, etc., can solve problems such as loud noise, affecting the life of washing machines, and increasing energy consumption of washing machines, so as to prevent the generation of dirt and prevent the growth of bacteria. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

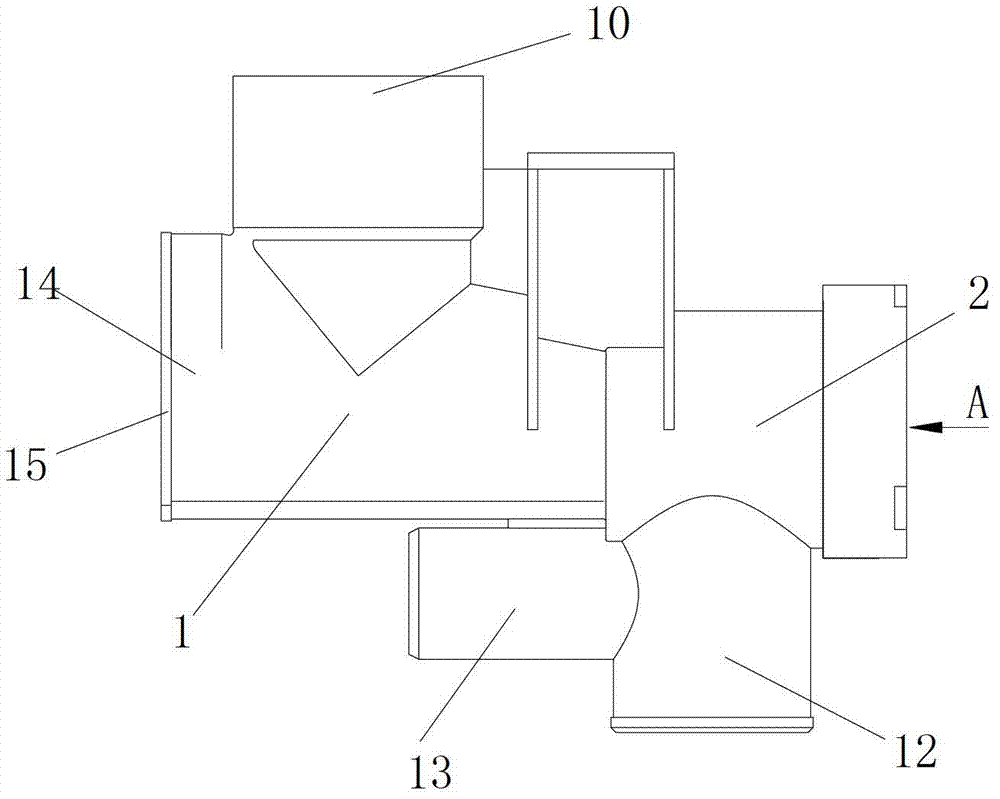

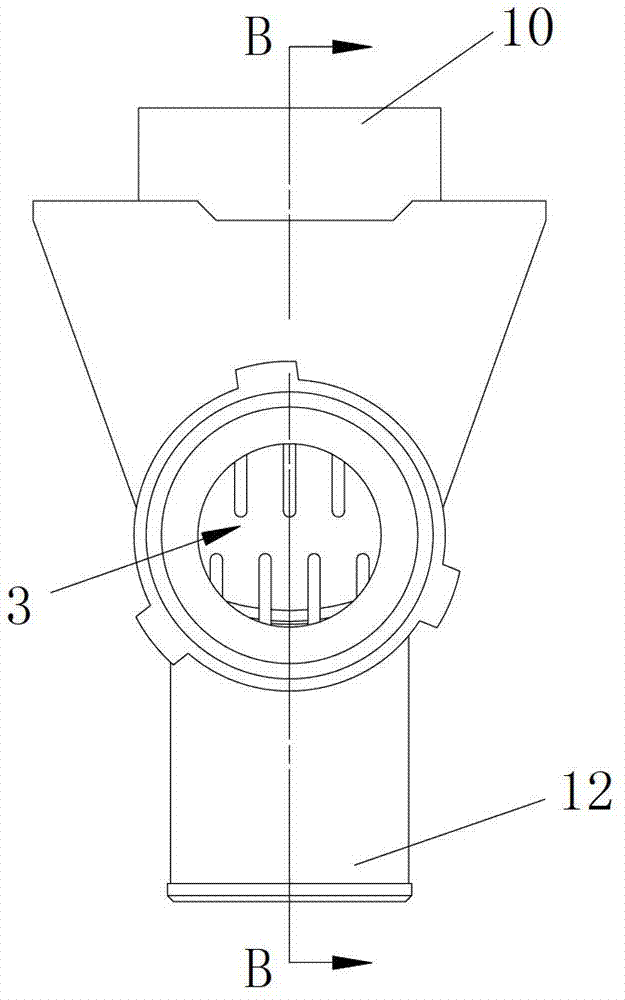

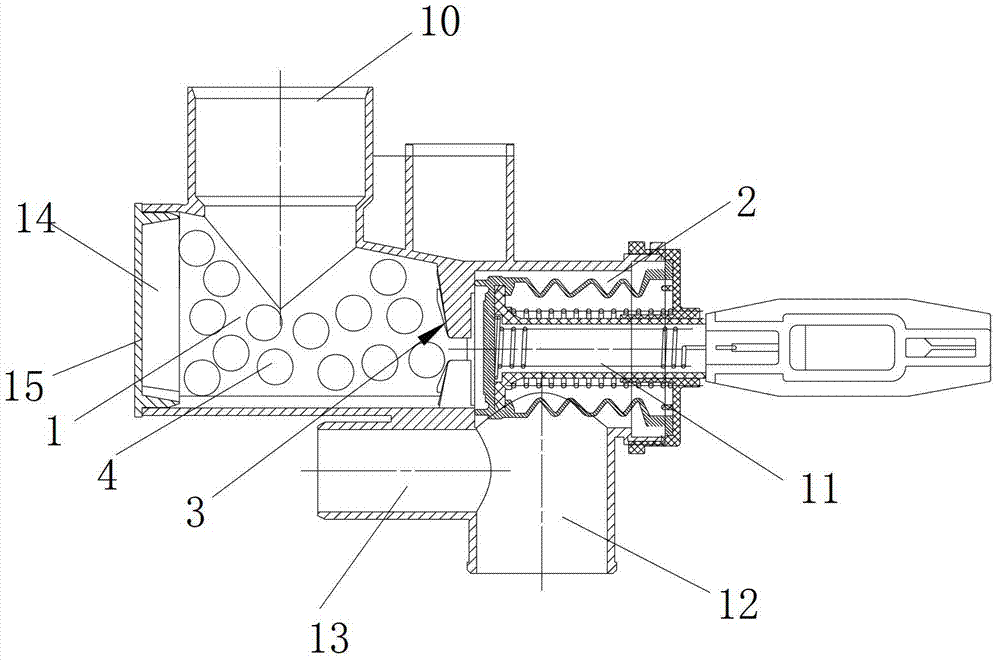

[0038] Such as Figure 4 As shown, in this embodiment, by controlling the rotation of the inner barrel during the drainage process, the cleaning particles stuck between the inner and outer barrel walls will fall off, and will be collected into the drain valve along with the drainage. Specifically: after washing, when draining, let the inner barrel rotate at a low speed of 5-50 rpm, generally 10-30 rpm, so that the cleaning balls stuck between the inner and outer barrel walls fall into the inner and outer barrels, and the cleaning particles 4 With the water flowing through the drain port, it enters the drain valve, and is filtered and collected by the filter structure 3 in the particle collection and release chamber 1 (see image 3 ).

Embodiment 2

[0040] Such as Figure 5 As shown, in this embodiment, in the spin-drying stage, by first drying at a medium speed, the water of the thrown out clothes is used to flush the particles left at the bottom of the outer tub to the drain valve, and then control the high-speed rotation and stop of the inner tub to remove the stuck clothes. The cleaning particles between the inner and outer barrel walls are shaken off and collected in the drain valve. The specific steps are:

[0041] a. After draining, the inner bucket first shakes the clothes water at a medium speed, and runs for 10-60 seconds to throw out most of the water in the clothes, so as to flush the cleaning particles left at the bottom of the outer bucket into the drain valve;

[0042] b. The inner barrel stops within 10-20 seconds after accelerating to high speed, to shake off the particles stuck between the inner and outer barrel walls;

[0043] c, repeat step b for 1-6 times, preferably 2-3 times;

[0044] d. Drying at ...

Embodiment 3

[0046] The difference between the present embodiment and the second embodiment is that the inner barrel is controlled to run continuously at a medium speed for 2-8 times at a medium speed according to the movement law of turning for 2-5 seconds and stopping for 5-15 seconds to repeat the inner barrel in step a of the second embodiment. - 60 seconds of action to shake the laundry water, preferably 4-6 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com