Rake drying method for drying sludge by utilization of high-temperature flue gas

A technology of high-temperature flue gas and rake drying, which is applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problems of low dissipation, low energy consumption, and low labor intensity, and achieve reduced resistance, reduced power consumption, and reduced Effect of power consumption and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

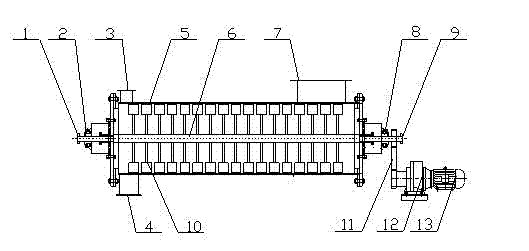

[0016] The invention relates to a rake drying method using high-temperature flue gas to dry sludge.

[0017] Drying is a process of high energy consumption. The larger the temperature difference between the inlet and outlet of the drying device, the higher the thermal efficiency of the drying process. Therefore, on the premise that the outlet temperature of the drying device remains unchanged, increasing the temperature of the heat medium at the inlet of the drying device can not only improve the pollution The thermal efficiency of the mud drying process can be improved, and the demand for heat medium in the drying process can be reduced, thereby reducing the installed capacity of the heat medium conveying device and reducing the power consumption of the drying process.

[0018] Sludge drying is a method of sludge disposal. The energy consumption of the drying process is directly related to the operating cost of sludge drying. Therefore, this invention uses the high-temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com