Poultry egg packaging mechanism with changeable egg fall distance

A variable, poultry-egg technology, applied in food packaging, egg packaging, dairy product packaging, etc., can solve the problem of no egg-dropping spacing packaging mechanism, etc., and achieve the effect of simple and complete structure, high efficiency and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

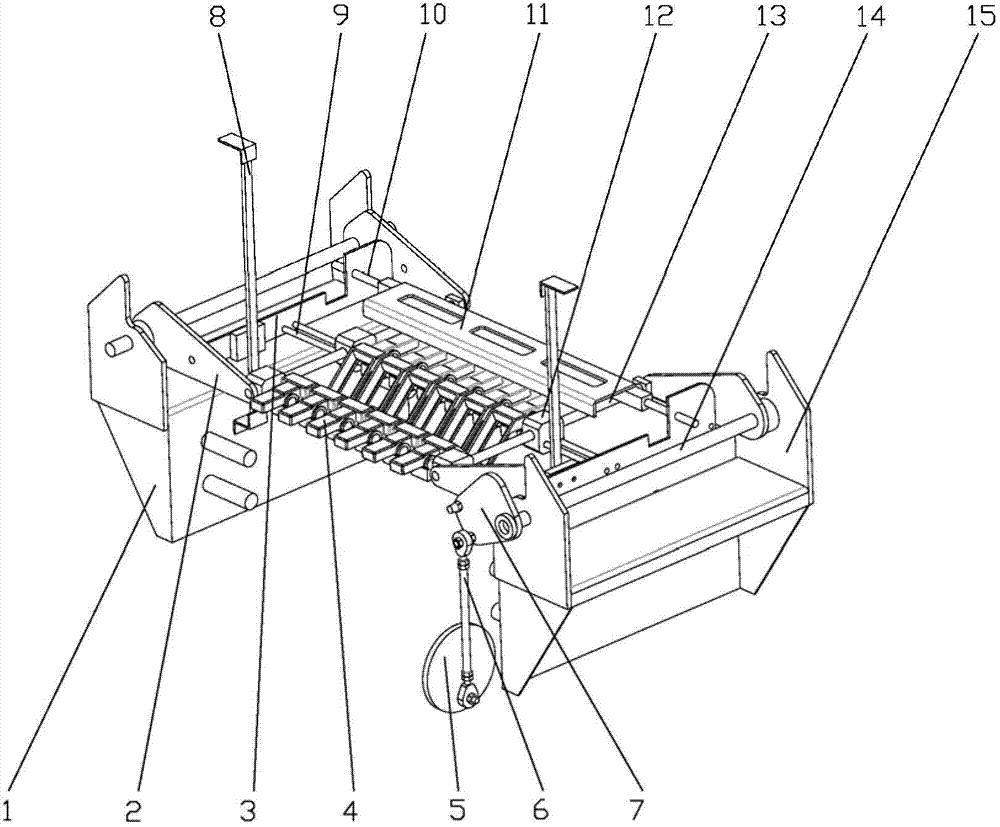

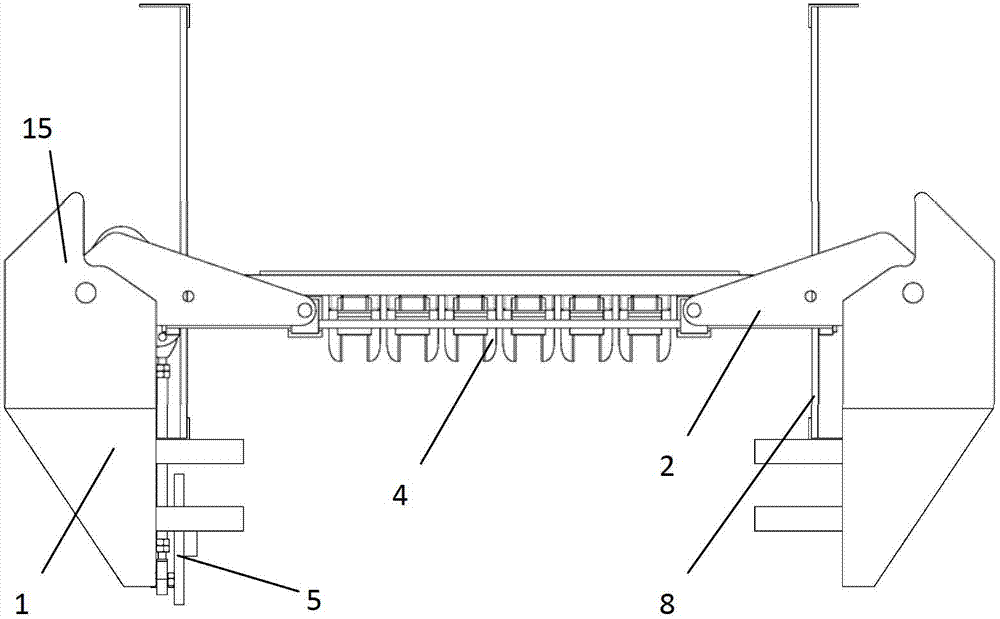

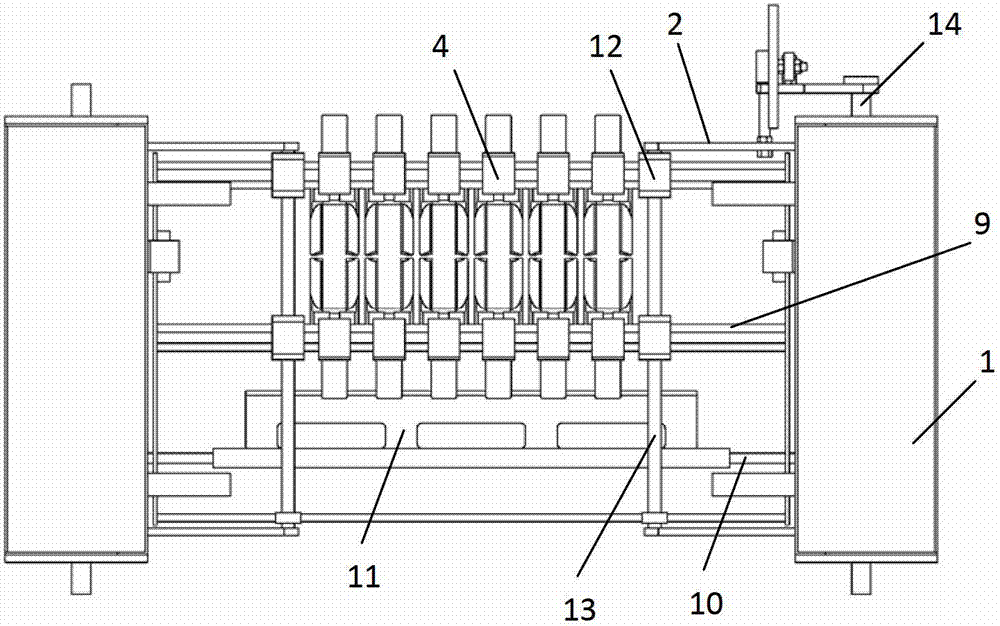

[0024] Such as figure 1 As shown, the present invention includes a supporting mechanism, two identical supporting bracket groups and a driving mechanism; the supporting mechanism is installed between the two supporting bracket groups, and the driving mechanism is installed on any one of the two supporting bracket groups. on the bracket set.

[0025] Such as figure 1 , image 3 As shown, the supporting mechanism includes two identical single-row egg bearing groups, two identical cross bars 13, cover plates 11, cover plate shafts 10 and two identical supporting clip group support pieces 3; Each single-row egg holding group includes N identical egg holding clips 4 arranged side by side, two identical slide blocks 12 and two identical transverse slide bars 13; the clip ends of the holding egg holding clips 4 are inclined downward, N The opposite end of each egg holder 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com