Packaging machine capable of being applied to sampling industry

A packing machine, sample collection and preparation technology, applied in packaging, transportation and packaging, capping with auxiliary devices, etc., can solve the problems of uneven transportation, failure to seal successfully, high labor intensity, etc., and achieve simplified storage and capping. Cover mechanism, prevent counterfeit and inferior products, and have high operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

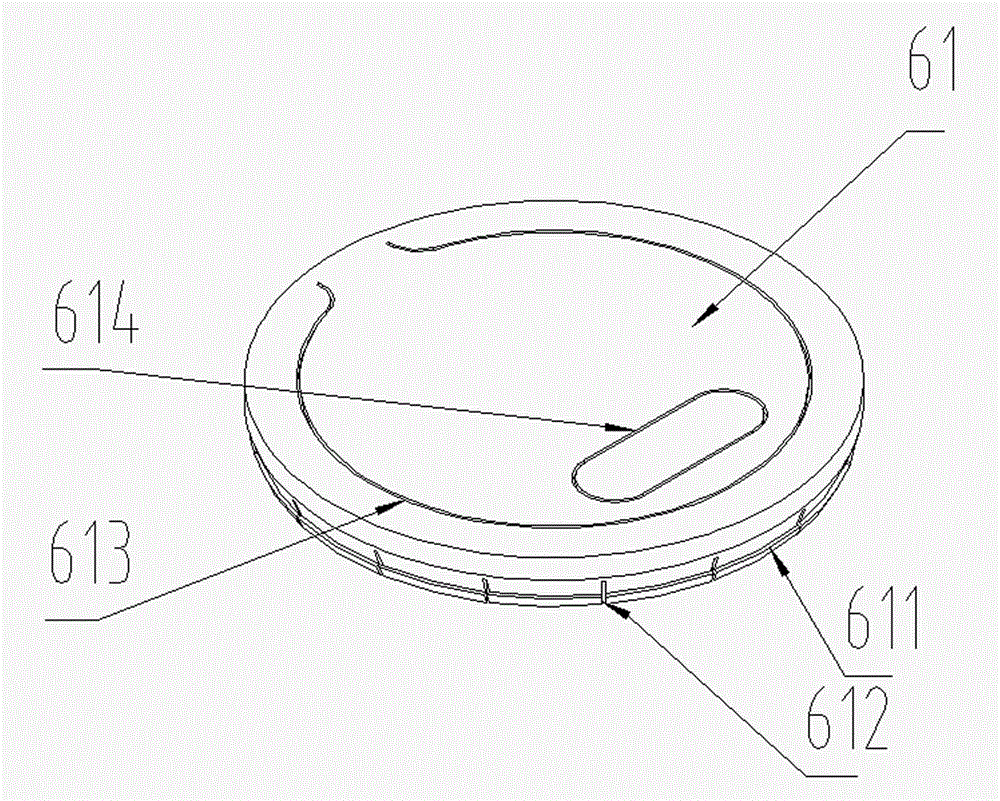

[0044] like Figure 2~Figure 4 As shown, the charging barrel 6 of the present embodiment is cylindrical, and the inner wall of the charging barrel 6 of the present embodiment is provided with an inwardly protruding annular extension 62 near its top, and the lower end of the bung 61 is provided with a The ring-shaped elastic slot 611 matched with the protruding part 62, the bung 61 is embedded in the barrel mouth of the charging barrel 6 through the pressure feeding of the automatic capping device 3, and the elastic slot 611 is embedded in the bung 61 to realize the Interference fit of protrusion 62 . A stress relief groove 612 is spaced apart from the annular elastic clamping groove 611 , which is more conducive to realizing a complete seal between the barrel cover 61 and the charging barrel 6 .

[0045] like image 3 As shown, in this embodiment, a non-closed ring is provided at the corresponding positions of the front side (that is, the visible outer side after sealing) an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com