Mold adjusting apparatus

A mold-adjusting device and mold-adjusting technology are applied in the field of mold-adjusting systems, which can solve the problems of unstable transmission, complex structure, and inconvenient mold-adjusting operation by mold-adjusters, and achieve stable transmission process, precise mold-adjustment control, and high transmission precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

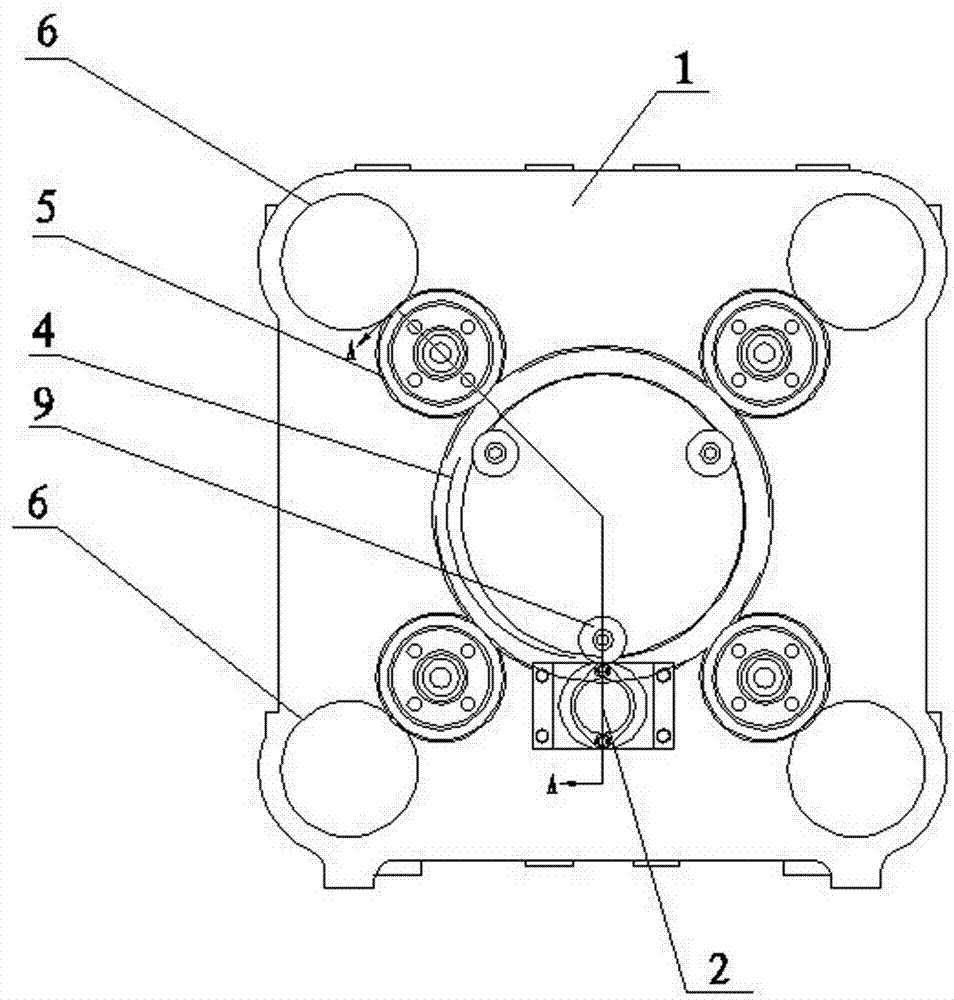

[0019] Such as figure 1 , figure 2 As shown, a mold adjusting device is installed on the end face of the mold adjusting template 1 of the injection molding machine. The oil motor 2 is supported and fixed on the adjusting template 1 by the mold adjusting motor seat 10. The first gear 3 (the module is 3.5 and the number of teeth is 20 , the diameter of the indexing circle is 70mm) is connected with the oil motor 2, the middle part of the adjusting plate 1 is provided with a ring gear 4, and the outer side of the ring gear 4 is evenly distributed with four second gears 5 (the module is 3.5, the number of teeth is 53, and the indexing The diameter of the circle is 185...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com