Hot rolling high-pressure fluid rust removing method and device

A high-pressure fluid and fluid technology, used in metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of uneven rust removal ability, improper manufacturing and installation of rust removal devices in the arrangement of nozzles 11, and reduce product surface. Rust skin defects, improving product surface quality, and improving the effect of rust removal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

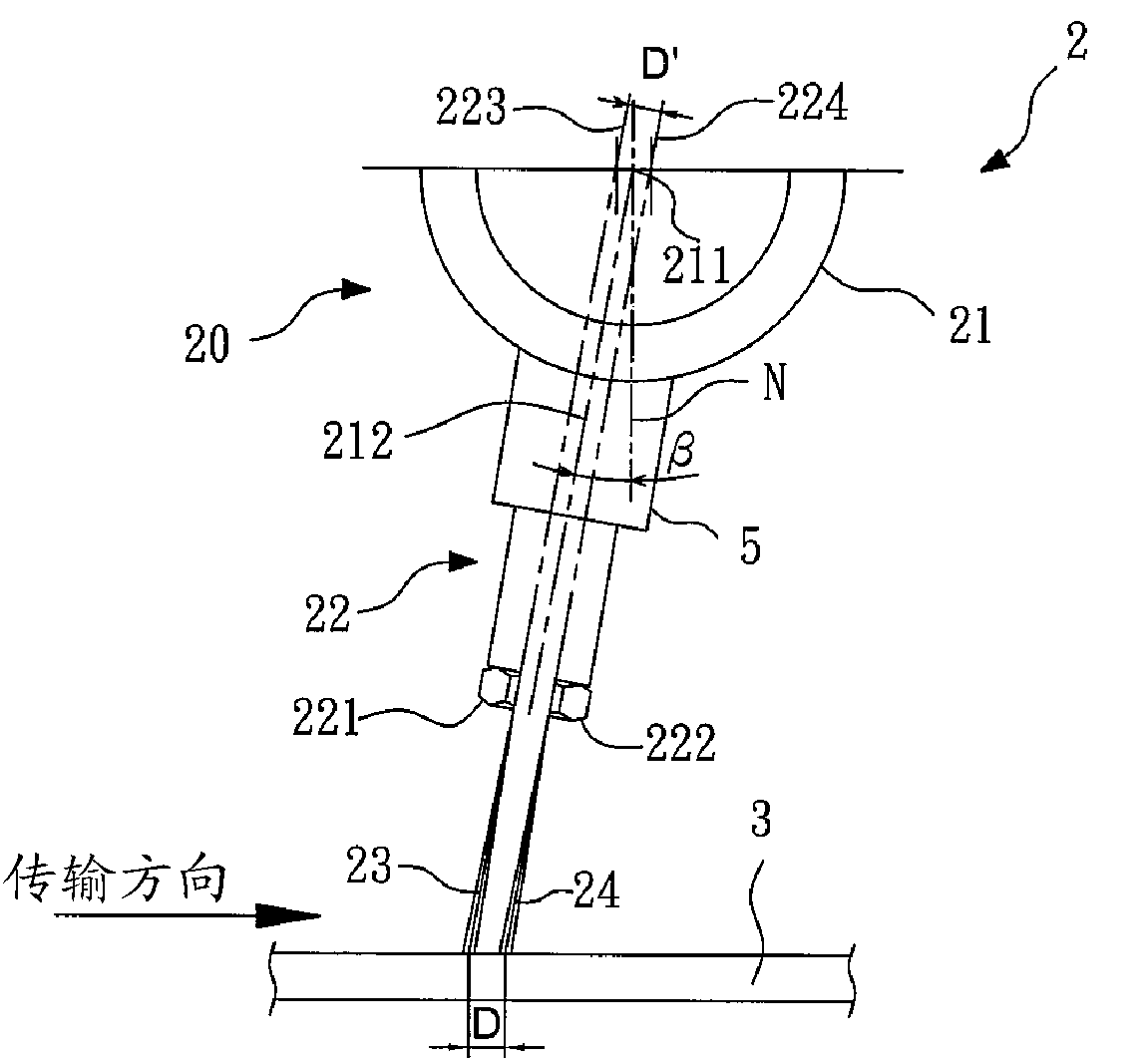

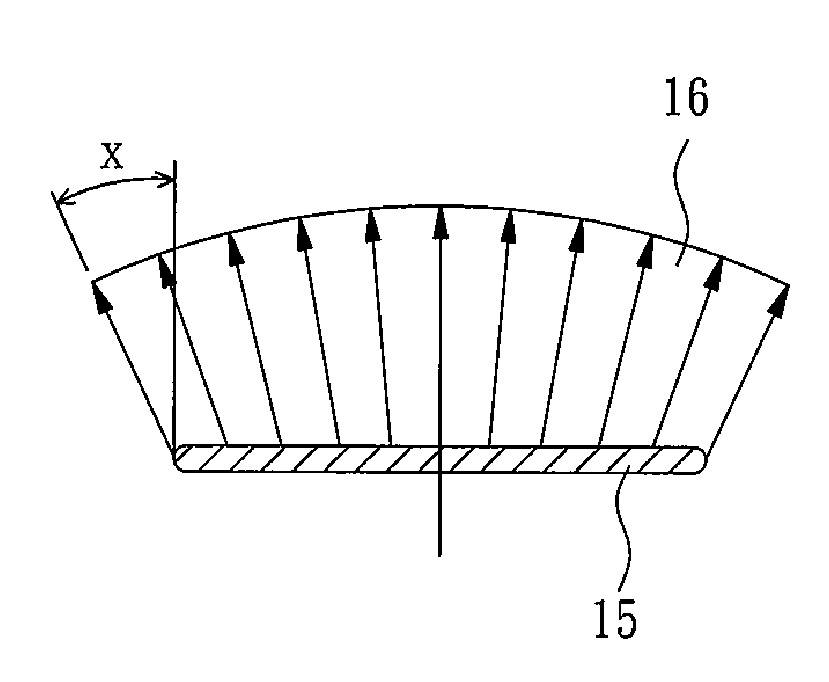

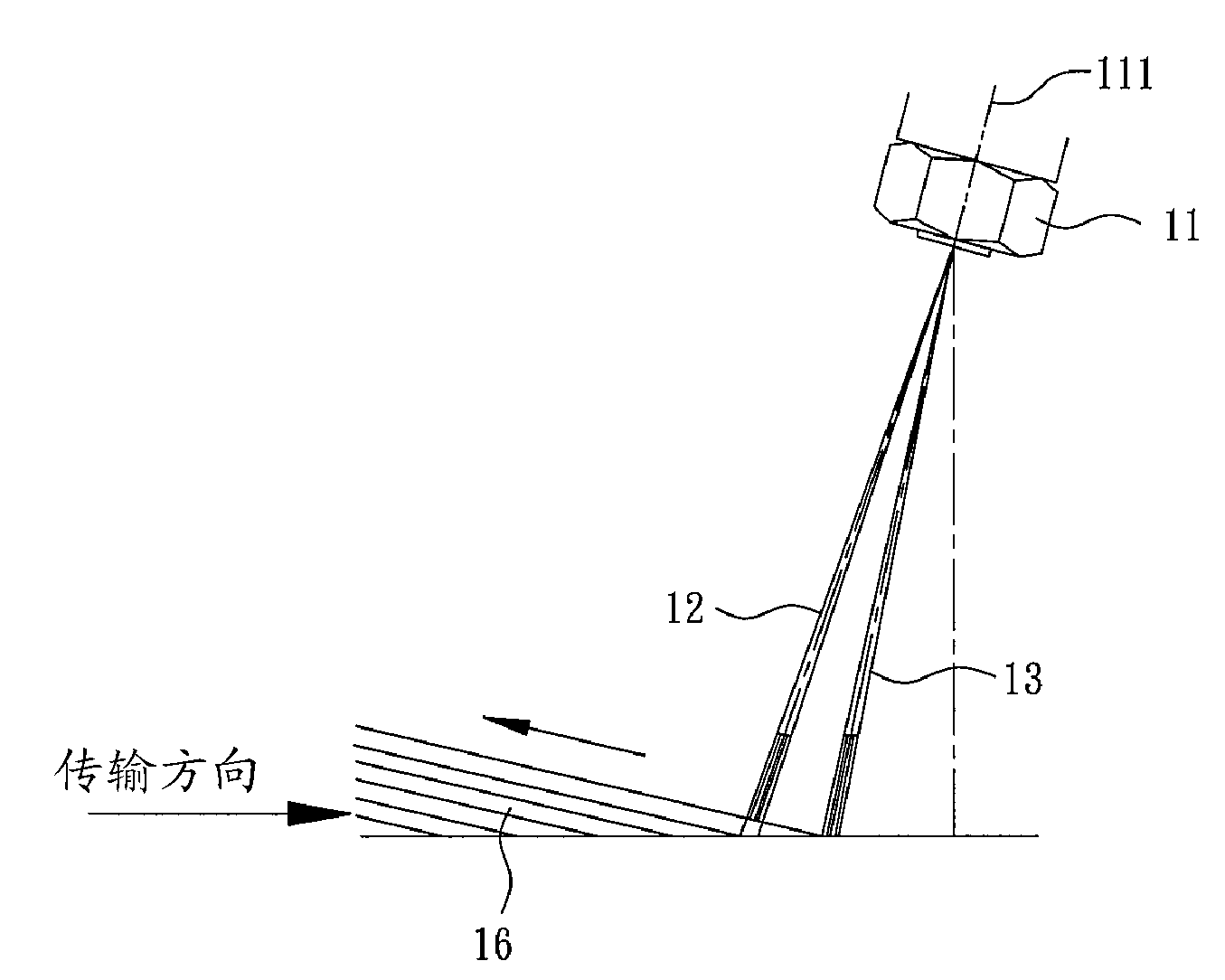

[0067] Figure 5 a shows the simulation schematic diagram of the impact area formed by the nozzle spray curtain of the hot rolling high pressure fluid rust removal device on the surface of the billet in the first embodiment of the present invention; Figure 5 b shows a schematic diagram of the rust removal nozzle arrangement of the hot rolling high pressure fluid rust removal device of the first embodiment of the present invention; Figure 5 c shows a side view of the hot-rolled high-pressure fluid rust removing device of the first embodiment of the present invention.

[0068] Combined reference Figure 5 From a to 5c, the hot rolling high-pressure fluid rust removing device 2 of the first embodiment of the present invention includes at least one rust removing unit 20, and the at least one rust removing unit 20 includes a main nozzle 21 and a plurality of nozzles 22. The length direction of the main nozzle 21 intersects with the billet conveying direction of the billet 3 to provide flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com