Control method of high-voltage electrostatic dedusting energy-saving device

A high-voltage electrostatic and control method technology, applied in the direction of electrostatic separation, power supply technology, etc., can solve problems such as large temperature difference, waste of electric energy, damage to porcelain sleeves, porcelain shafts, etc., and achieve the effects of prolonging life, reducing maintenance costs, and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

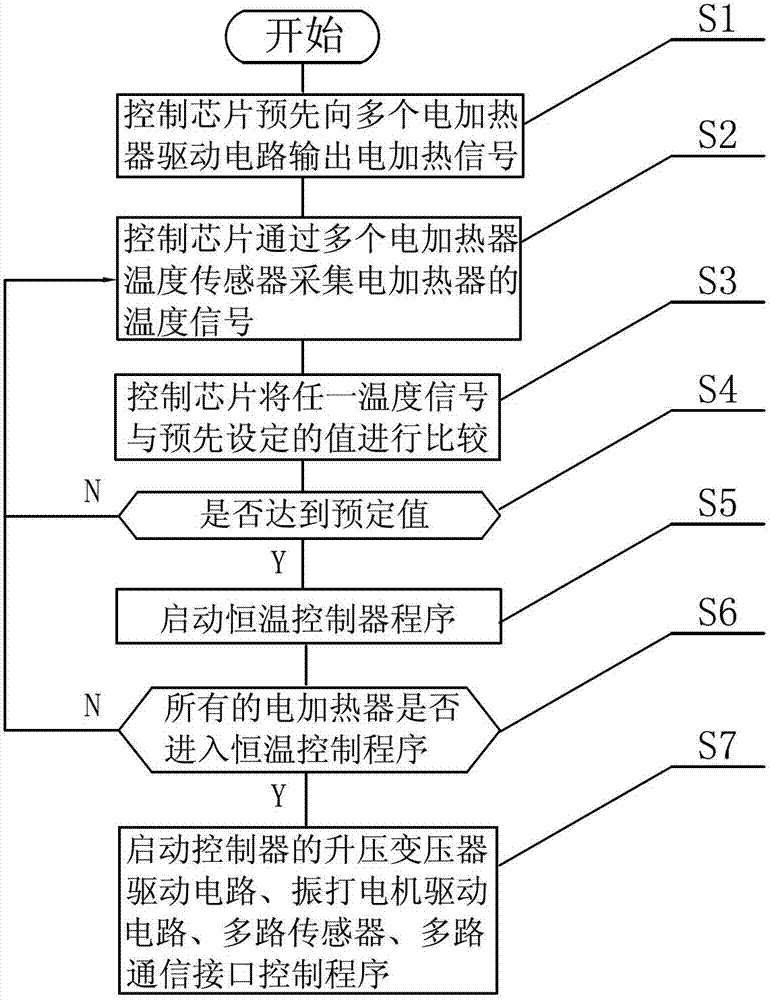

[0015] Such as figure 1 As shown, a control method for high-voltage electrostatic precipitator and energy-saving equipment is applied to a high-voltage electrostatic precipitator energy-saving controller. drive circuit, multiple electric heater drive circuits, the control chip is respectively connected with multiple sensors, multiple communication interfaces, step-up transformer drive circuits, rapping motor drive circuits, multiple electric heater drive circuits, the controller’s The control method comprises the steps of:

[0016] The S1 control chip outputs electric heating signals to multiple electric heater drive circuits in advance;

[0017] The S2 control chip collects the temperature signal of the electric heater through multiple electric heater temperature sensors;

[0018] The S3 control chip compares any temperature signal with a preset value;

[0019] S4 judges whether to reach predetermined value, if not, repeat step S2; If yes,

[0020] S5 starts the constant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com