Slurry bed reaction equipment

A technology of reaction equipment and slurry bed, which is applied in the field of Fischer-Tropsch synthesis, can solve problems such as uneven axial distribution of catalysts, and achieve the effects of enhancing backmixing, overcoming deposition, and promoting uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions in the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings in the embodiments of the present invention, but the following embodiments and accompanying drawings are only used to understand the present invention, rather than limit the present invention, the present invention can A multitude of different implementations are defined and covered by the claims.

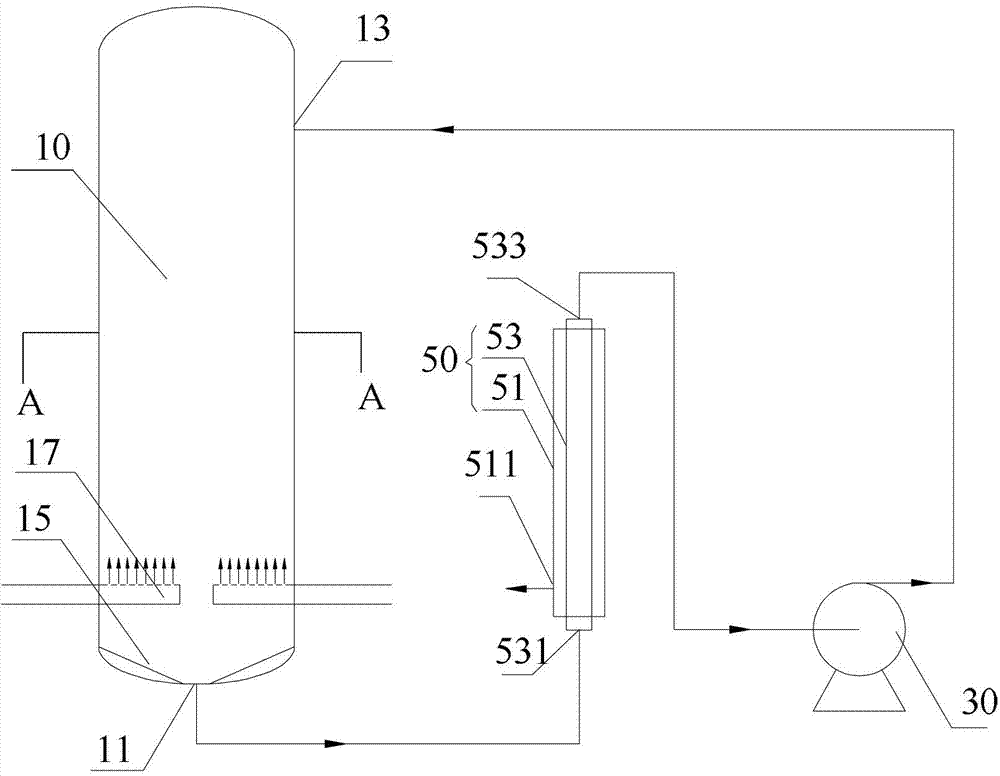

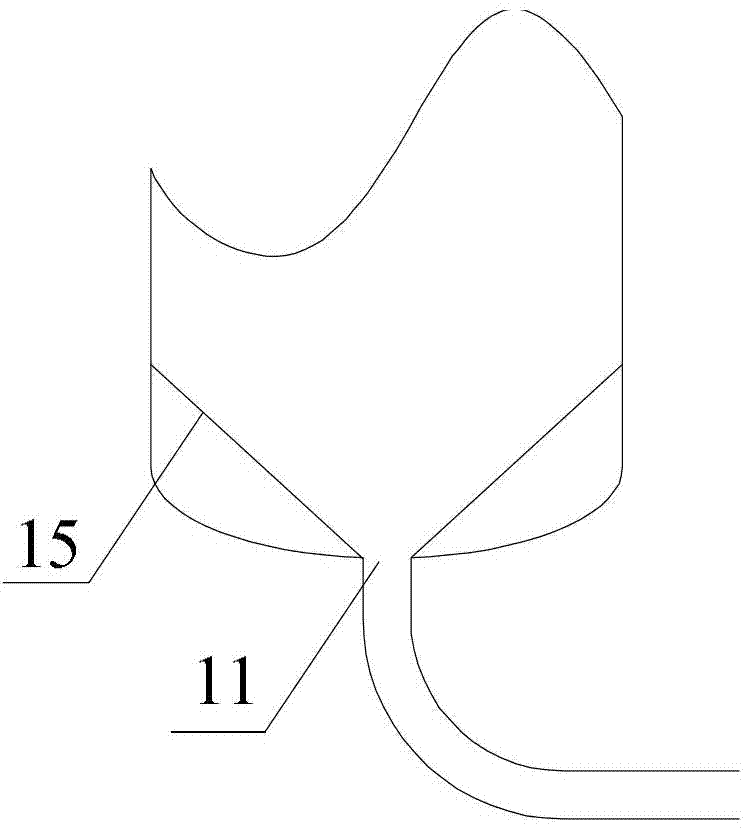

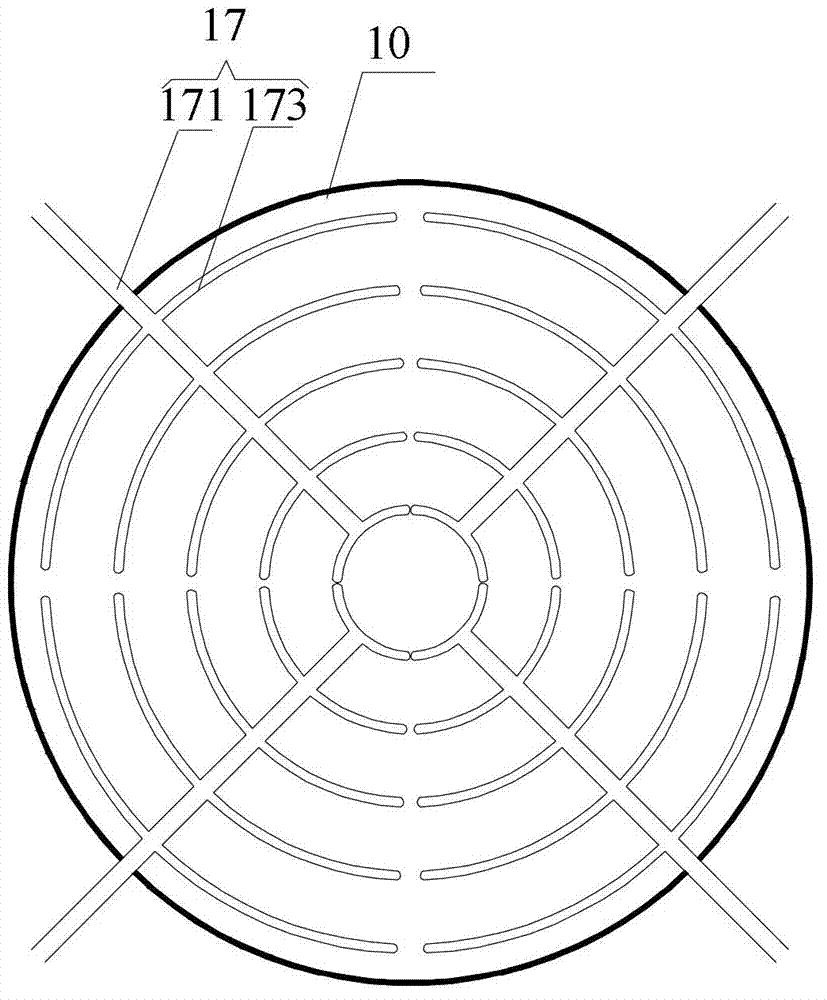

[0030] Such as figure 1 As shown, in one embodiment of the present invention, a slurry bed reaction device is provided, which includes a slurry bed reactor 10 and an extraction device 30 . Slurry bed reactor 10 comprises the slurry outlet 11 that is arranged on its bottom and the return slurry inlet 13 that is positioned at its top; Extractor 30 is connected between slurry outlet 11 and returns slurry inlet 13, is used for slurry bed reactor The slurry at the bottom of 10 is withdrawn and lifted back to the upper part of the slu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com