Countercurrent pot-type reaction device for supercritical water treatment of waste organic matter

A supercritical water and reaction device technology, which is applied in the fields of solid waste removal, heating water/sewage treatment, oxidized water/sewage treatment, etc. It can solve the problems of difficult disassembly, short service life of catalysts, blockage of reactor inlet and outlet pipelines, etc. problem, achieve the effect of overcoming deposition and agglomeration, delaying corrosion rate, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

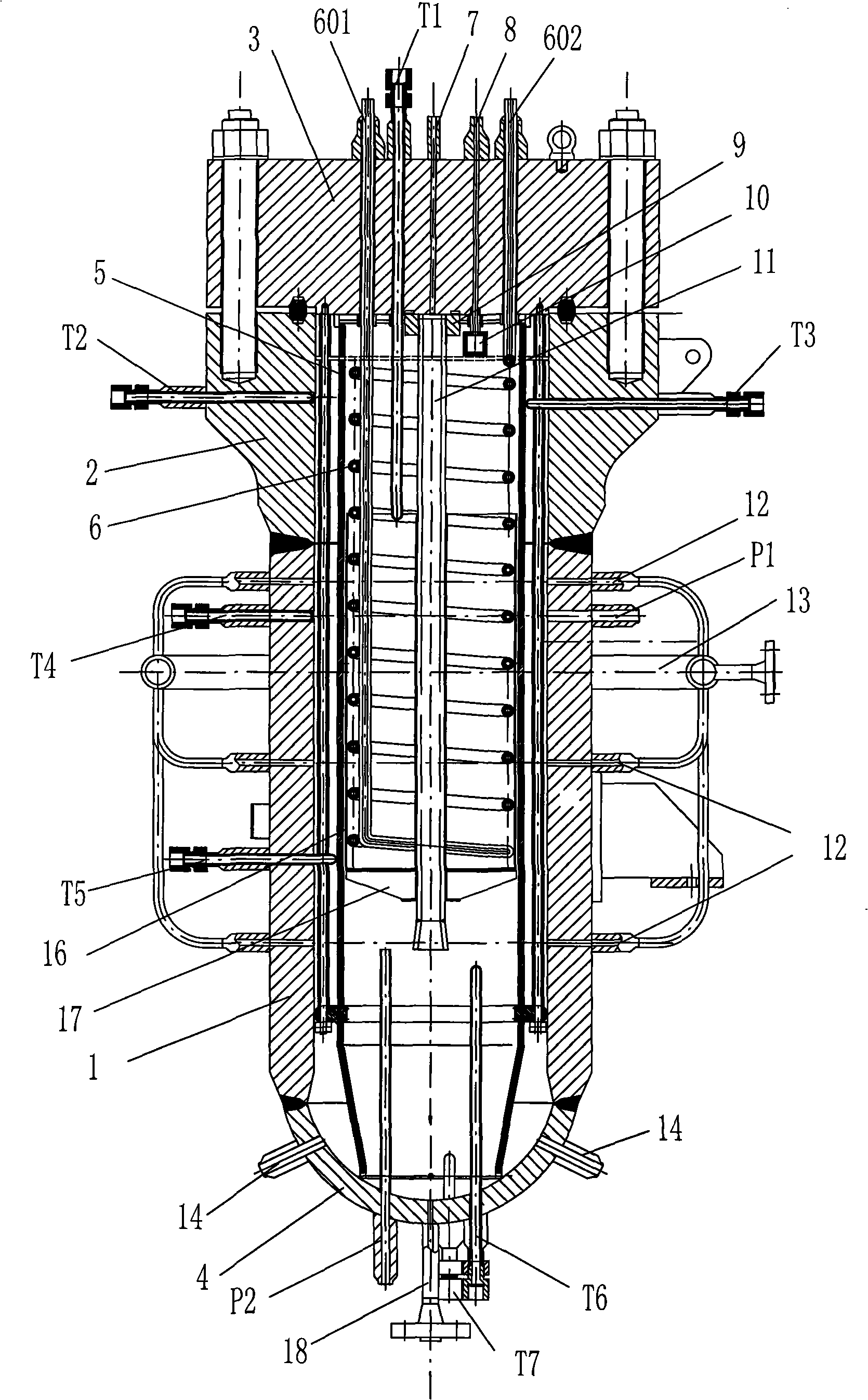

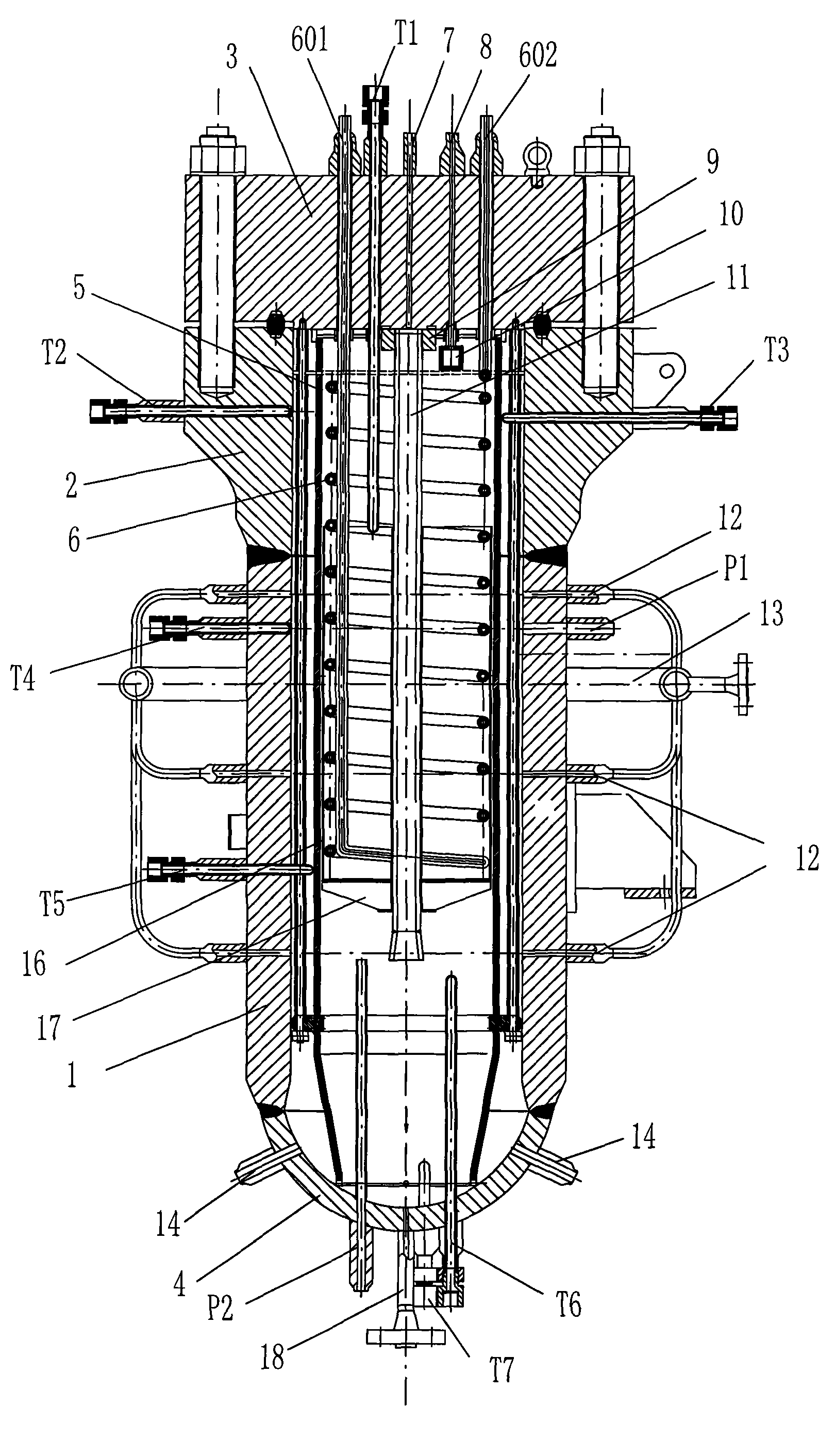

[0025] refer to figure 1 , a countercurrent tank reaction device for supercritical water treatment of waste organic matter, mainly including: a cylinder body 1, an end cover 3, a spherical head 4, an evaporation wall 5, a heat exchange coil 6, and a material inlet pipe 7, which are arranged on the end cover The central conduit 11 at the bottom, the reaction outlet pipe 8, the water inlet pipes 12 and 14 for evaporating wall water, the salt discharge pipe 18, the catalyst box 16 and related temperature and pressure sensors, etc.

[0026] The cylinder body is composed of a straight cylinder part 1 and an upper end part 2 welded, a spherical head 3 is welded on the lower end of the cylinder body straight cylinder part 1, an octagonal gasket is arranged between the cylinder upper end part 2 and the end cover 3, and it is fixed by a stud bolt . The evaporation wall 5 is made of sintered metal mesh, which is arranged in the cylinder with a gap with the inner wall of the cylinder, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com