Pulse reverse-blowing ash-removing device with rotary blowing pipes

A technology of pulse backflushing and ash cleaning device, which is used in the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles, etc. Air deflection and other problems, to overcome the uneven air flow of backflushing, increase the cleaning efficiency and backflushing intensity, and reduce the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

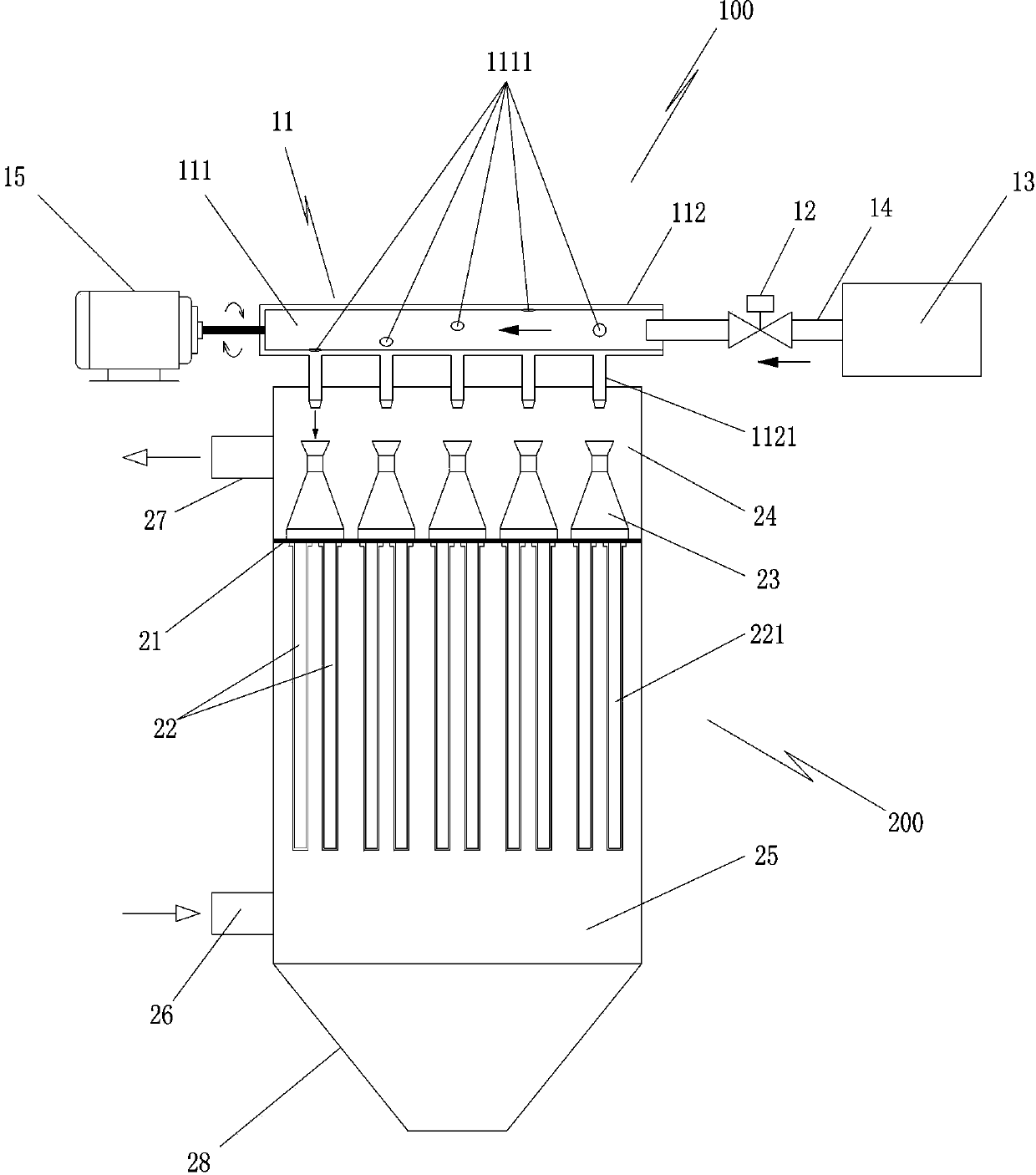

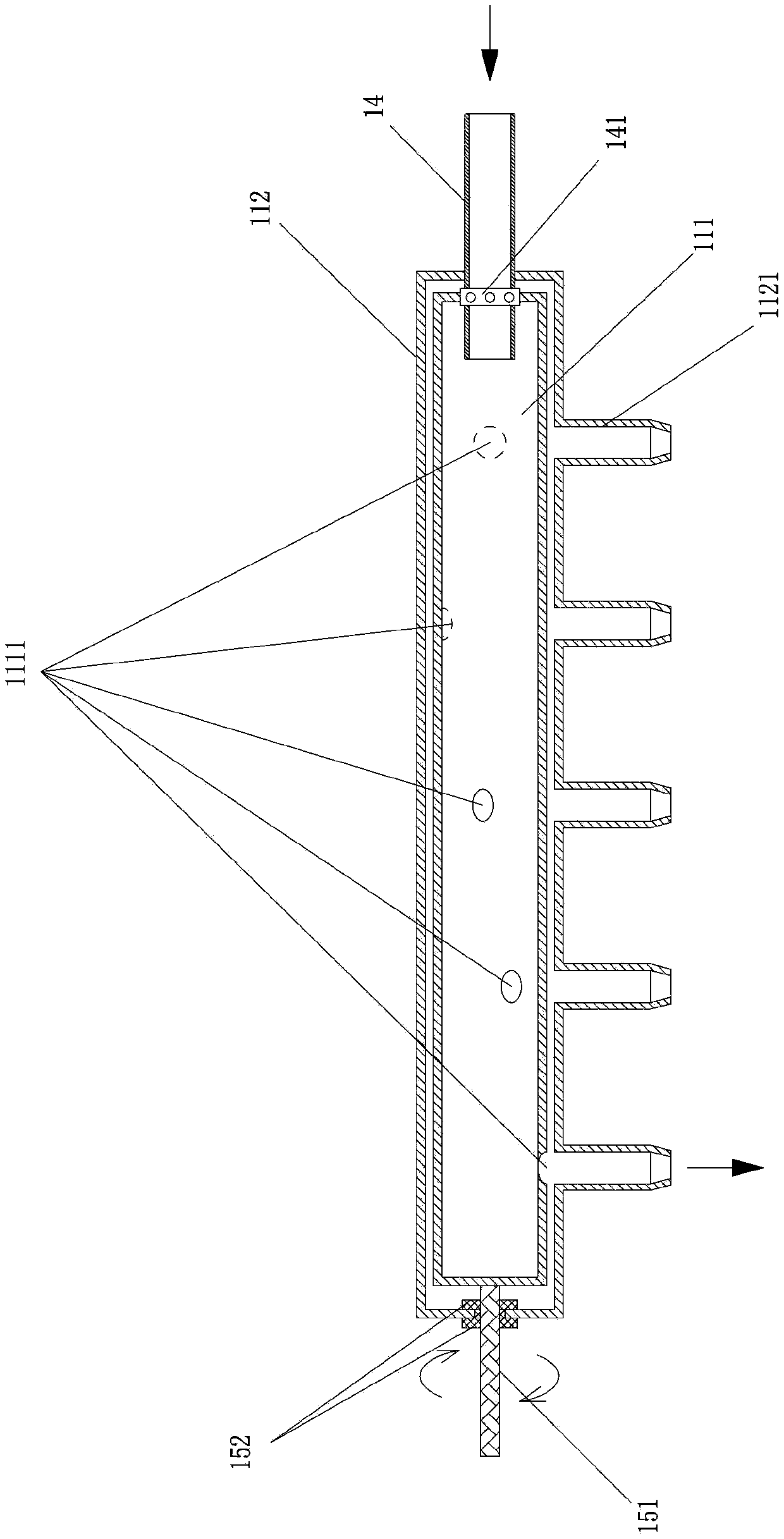

[0038] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

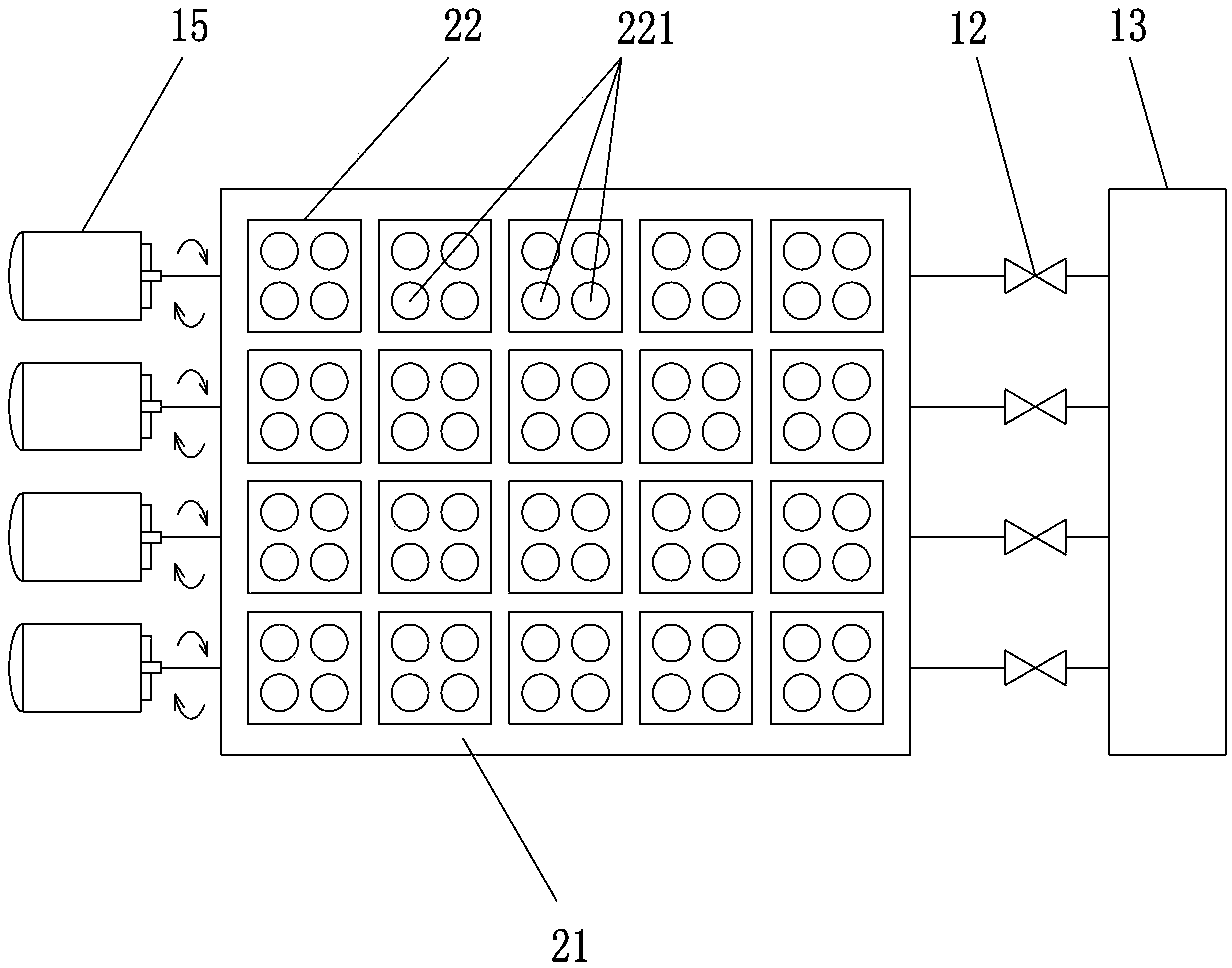

[0039] Such as Figure 1A As shown, the present invention proposes a pulse back-blowing soot cleaning device 100 with a rotary blowing pipe, and the pulse back-blowing soot cleaning device 100 is arranged on the top of the filter 200, and There are multiple rows of filter units 22 arranged longitudinally at intervals, and each row is provided with the same number of filter units arranged at intervals; the upper side of the tube plate 21 is provided with a gas injector 23 corresponding to each group of filter units 22; the filter The tube plate 21 seals and separates the filter into an upper clean gas chamber 24 and a lower dusty gas chamber 25, the dusty gas chamber 25 is provided with a dusty gas inlet 26, and the clean gas cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com