Dumpling former with nonstick template

A former and template technology, applied in the fields of dough processing, baking, food science, etc., can solve the problems of easy falling off of the coating, high cost, easy aging, etc., so as to reduce cumbersome procedures, improve service life, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

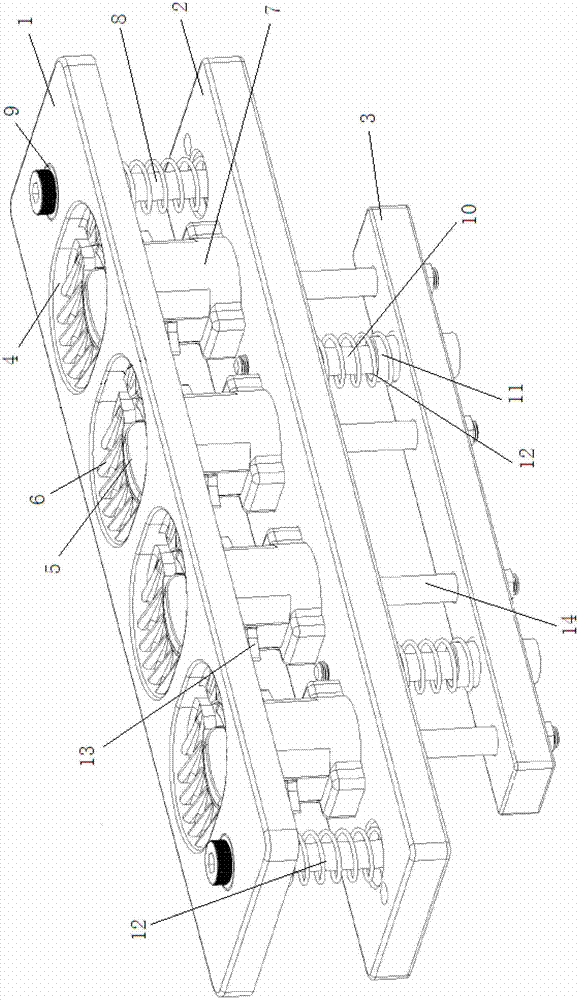

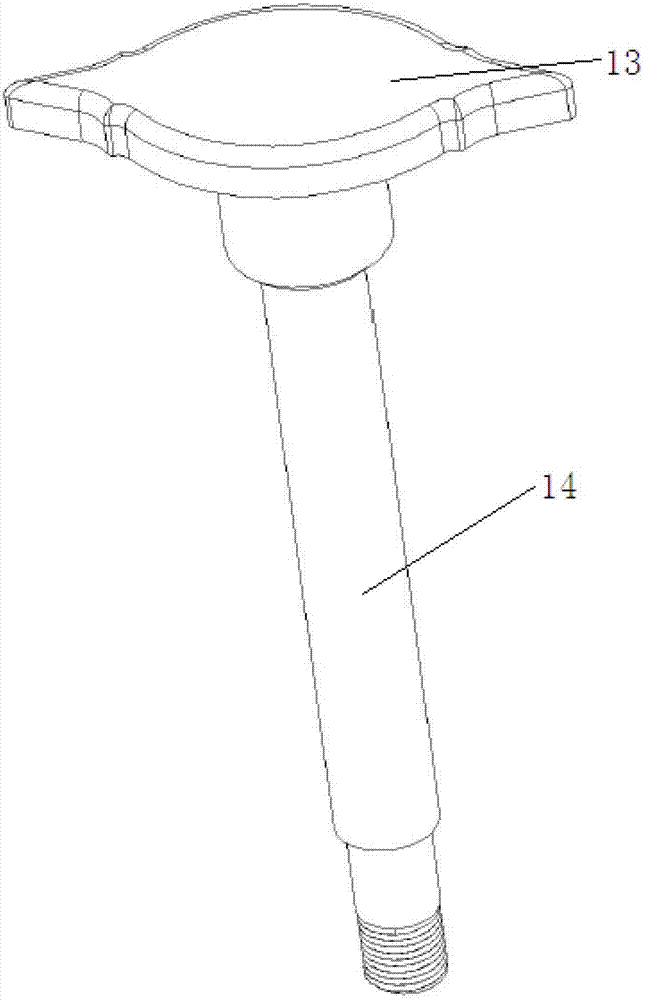

[0012] Such as figure 1 and figure 2 Shown, a kind of dumpling former with non-stick surface formwork comprises movable formwork 1, fixed formwork 2 and ejection formwork 3, has several grooves 4 on the longitudinal direction of described mobile formwork 1, and described groove 4 There is a perforation 5 at the bottom of the groove, and several inclined ribs 6 arranged horizontally are arranged on the grooves on both sides of the perforation 5. The cross-sectional area of the inclined ribs 6 gradually narrows from the upper end to the lower end. Forming mold 7 corresponding to groove 4 is fixedly installed on template 2, and described forming mold 7 forms a hollow cavity, and described forming mold 7 can move in perforation 5, between described fixed template 2 and movable template 1 Through the sliding connection of the guide post 8 and the guide sleeve 9, and a spring 12 is pressed between them, a threaded ejector plate guide post 10 is screwed under the fixed template 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com