Combined sugarcane harvester

A combine harvester and harvester technology, applied to harvesters, agricultural machinery and implements, applications, etc., can solve the problems of unfavorable raw material sugarcane preservation, waste cane tail removal, unfavorable harvesting, etc., to reduce the impurity content of material cane, The effect of reducing the loss of material cane and avoiding the waste of material cane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

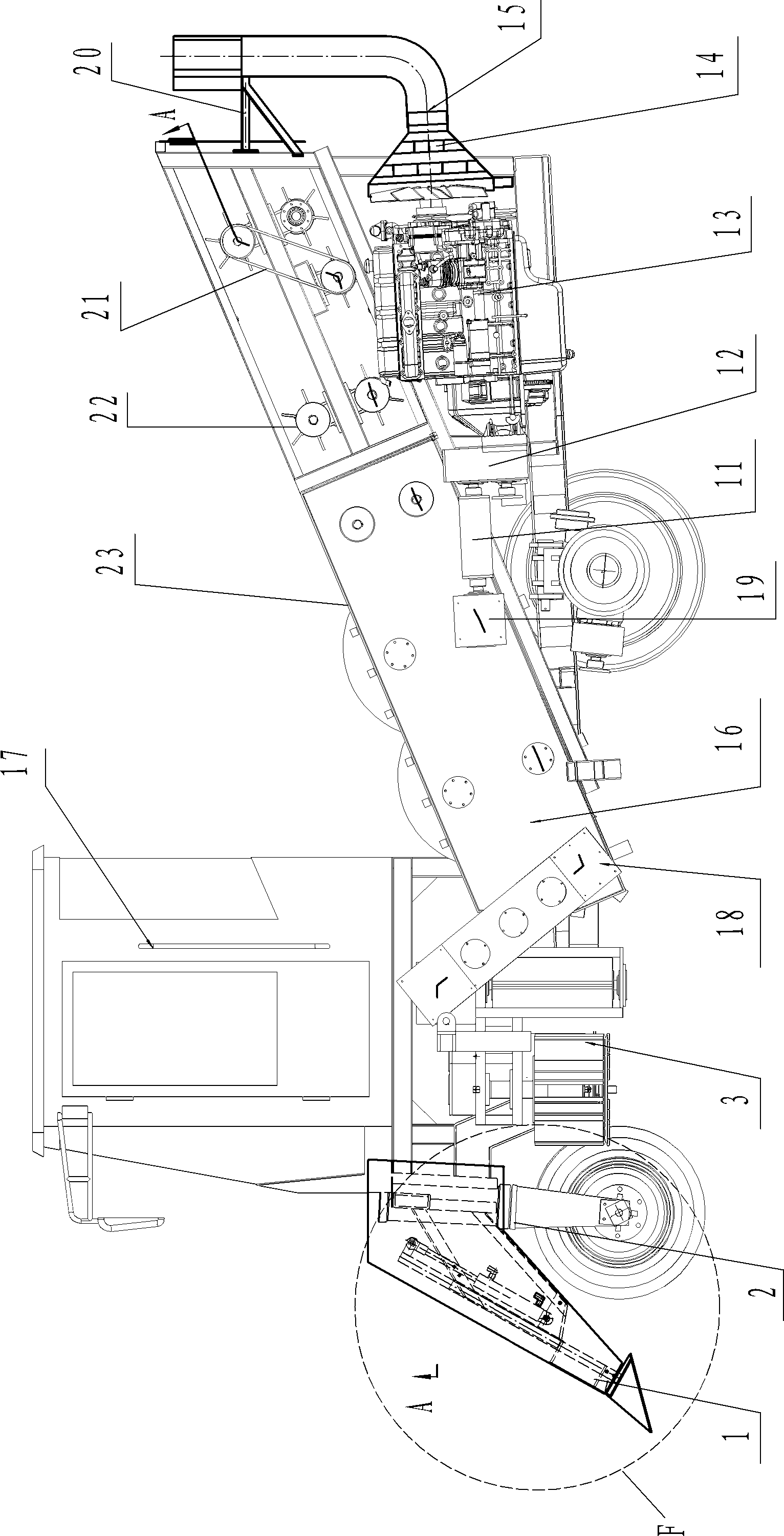

[0039] Such as Figure 1 to Figure 4 As shown, the sugarcane combine harvester of the present invention includes a gantry front axle device 2 connected to the front end of the vehicle frame 29, two groups of separation mechanisms 1 symmetrically arranged on both sides before the front wheel of the sugarcane harvester, and a gantry front axle device 2 located at the front end of the gantry harvester. The rear side is connected to the harvester cab 17 below in order to cut sugarcane and the header device 3 that sugarcane is transported backward, is connected to the header device 3 rear end and is fixed on the channel device 16 on the vehicle frame 29, is fixed on The engine 13 on the vehicle frame 29 and on the outer side of the channel device 16 .

[0040] Please combine Image 6 As shown, the gantry front axle device 2 includes left and right front forks 34, left and right inner steering metal cylinders 44, left and right outer metal cylinders 35, upper and lower steering bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com