XY motion platform driven by double-layer linear motor

A technology of linear motors and motion platforms, applied in the direction of multiple motor speed adjustments, circuits, electrical components, etc., can solve the problems of large structure size, small platform drive capacity, high manufacturing cost, etc., and achieve high motion acceleration and speed, structure The effect of compact size and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

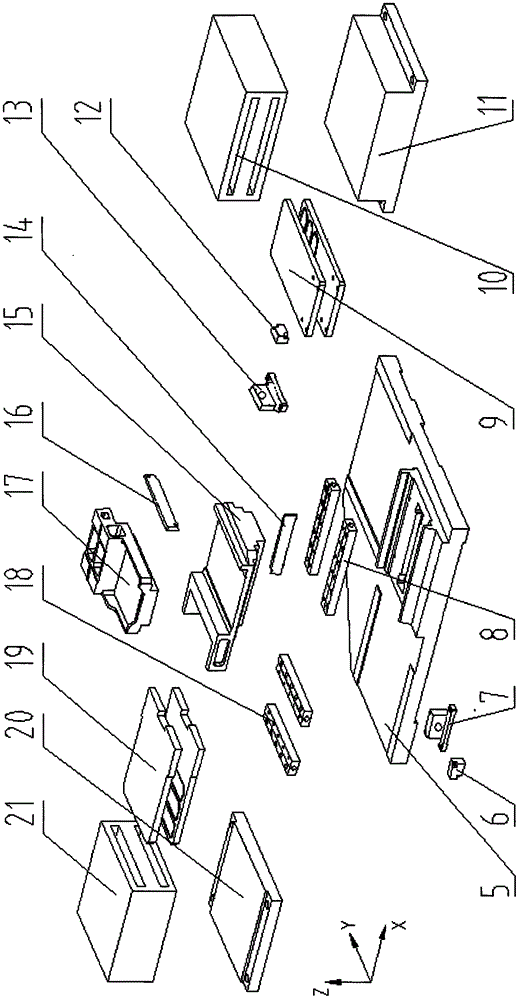

[0026] The present invention will be further explained in conjunction with the drawings:

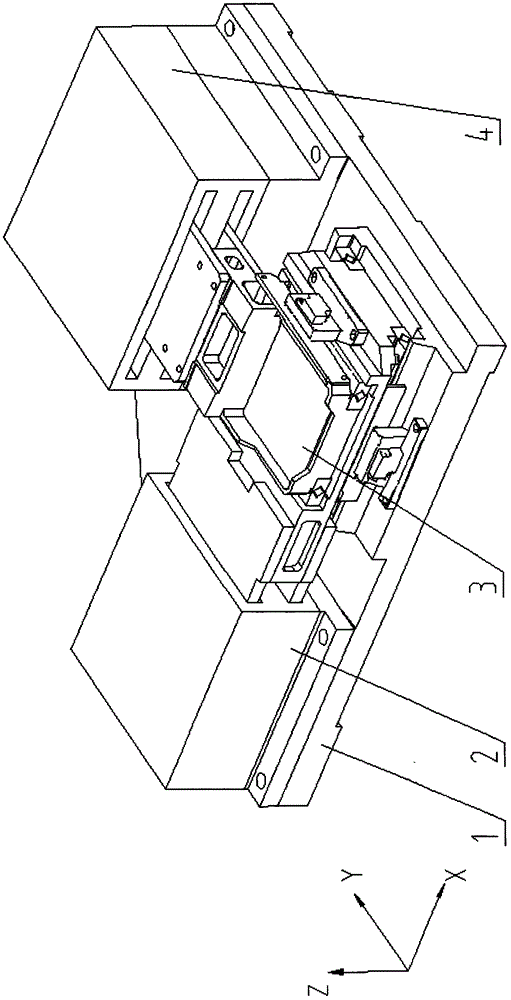

[0027] Reference figure 1 , figure 2 As shown, a double-layer linear motor driven XY motion platform includes: base plate assembly 1, X-axis linear motor assembly 2, motion platform assembly 3, Y-axis linear motor assembly 4, base plate 5, X-axis grating ruler reading head 6, X-axis grating scale reading head angle 7, X-axis precision motion guide 8, Y-axis linear motor mover 9, Y-axis linear motor stator and housing 10, Y-axis linear motor mounting seat 11, Y-axis grating ruler reading head 12, Y-axis grating ruler reading head angle frame 13, X-axis grating ruler frame 14, X-axis motion connecting frame 15, Y-axis grating ruler frame 16, Y-axis motion connecting frame 17, Y-axis precision motion guide 18, X-axis linear motor mover 19. X-axis linear motor mounting base 20, X-axis linear motor stator and housing 21.

[0028] The connection mode of the components of the XY motion platform d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com