Method for slowing down aging of solid insulation of oil-paper insulating transformer

A solid insulation, oil-paper insulation technology, applied in the direction of transformer/inductor coil/winding/connection, instrument, non-electrical variable control, etc., can solve the rough and simple control principle, the lack of monitoring and reflection of the hot spot temperature of the transformer winding, and the uncontrollable Problems such as accelerated aging of transformer solid insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

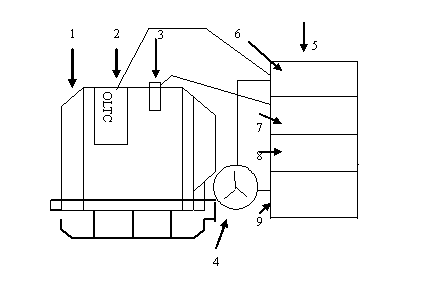

[0050] Using the transformer in actual operation, establish a transformer winding hot spot temperature measurement, calculation and cooling control system as attached figure 1 shown. In this system, the control method proposed by the present invention operates according to the following steps:

[0051] The first step is to use the actual operating transformer to establish a transformer winding hot spot temperature measurement, calculation and cooling control system, as shown in the attached figure 1 As shown; the transformer cooling system control device 5 uses the temperature measurement module 7 to obtain the top oil of the transformer provided by the top oil temperature sensor 3, and the temperature is used to calculate the temperature of the transformer winding; the tap position of the voltage regulating device and the fan state acquisition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com