Device and method for detecting whole satellite leak rate of satellite

A detection device, detection method technology, applied in the direction of detecting the presence of fluid at the leak point, using liquid/vacuum for liquid tightness measurement, etc., can solve engine diffuser cooling pipe leakage, launch failure, political influence and economic Loss and other problems, to achieve the effect of shortening data processing time, shortening leak detection cycle, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

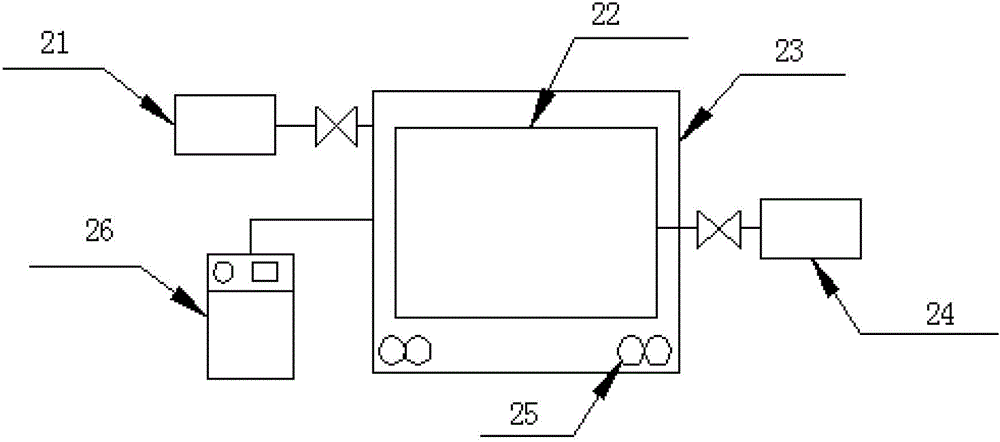

[0043] Such as figure 1 and figure 2 As shown, the present embodiment includes a leak detection gas collection box 23, a calibration device 21, an inflation and deflation device 24, a circulation fan 25 and a helium mass spectrometer leak detector 26, and the satellite 22 is installed inside the leak detection gas collection box 23, wherein the detection The leakage gas collection box 23 is respectively connected with the calibration device 21 and the inflation and deflation device 24 through the manual fine-tuning vacuum valve 13, the helium mass spectrometer leak detector 26 is connected to the leak detection gas collection box 23, and the circulation fan 25 is installed on the leak detection gas collection box 23. Inside box 23.

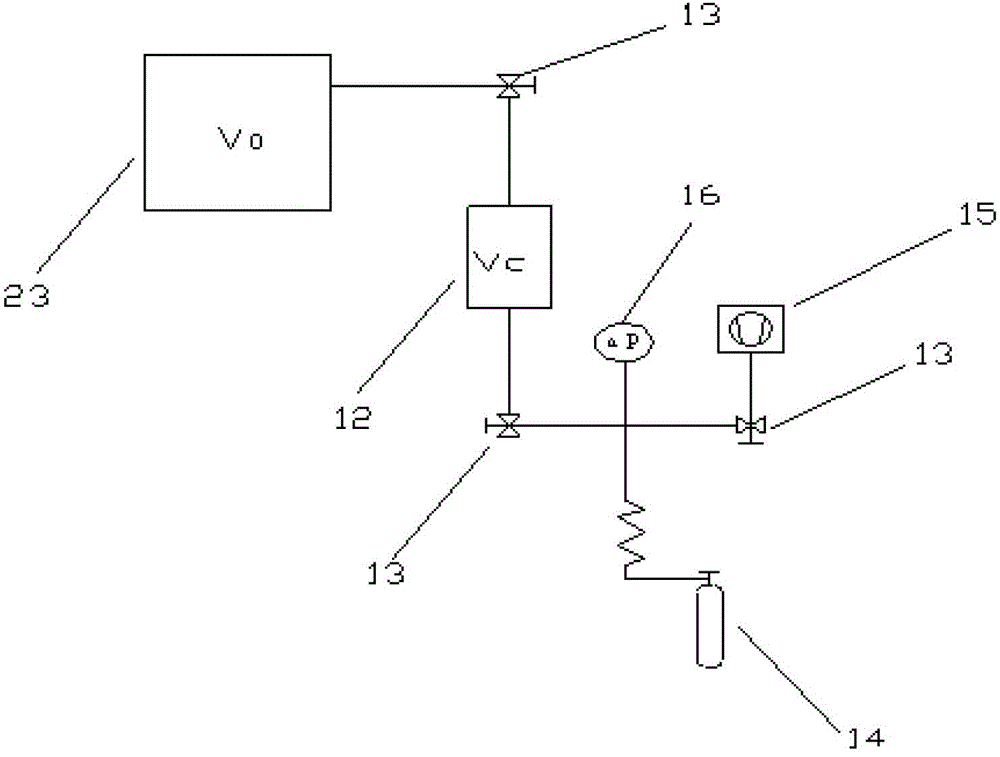

[0044] In this embodiment, the calibration device 21 includes a helium cylinder 14, a standard container 12 and a pressure vacuum gauge 16. The helium cylinder 14 is connected to the standard container 12 through a manual fine-tuning vacuum valv...

Embodiment 2

[0047] Embodiment 2 is a detection method utilizing the satellite whole-satellite leakage rate detection device provided in Embodiment 1.

[0048] This embodiment includes the following steps:

[0049] Step 1, calibration: use the calibration device to obtain the calibration curve in the leak detection gas collection box;

[0050] The first step is to check the pressure in the satellite and whether it is filled with helium. If there is pressure, the pressure should be restored to an atmospheric pressure. If there is helium, replace it with 0.3MPa high-purity nitrogen for no less than three times.

[0051] The second step is to check the leak detection gas collection box and purge the satellite with high-purity nitrogen, and use the sniffing gun method to detect that the background concentration of helium in the box is not higher than the surrounding environment;

[0052] The third step is to put the satellite into the leak detection gas collection box and seal the leak detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com