Trolley traction device

The technology of a traction device and a trolley is applied in the directions of furnaces, lighting and heating equipment, furnace components, etc., which can solve the problems of shortening the service life of the trolley, large workload and labor cost, and cooling deformation of the horn, and achieves a simple structure, The effect of reducing manufacturing and construction costs and preventing cold and heat deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

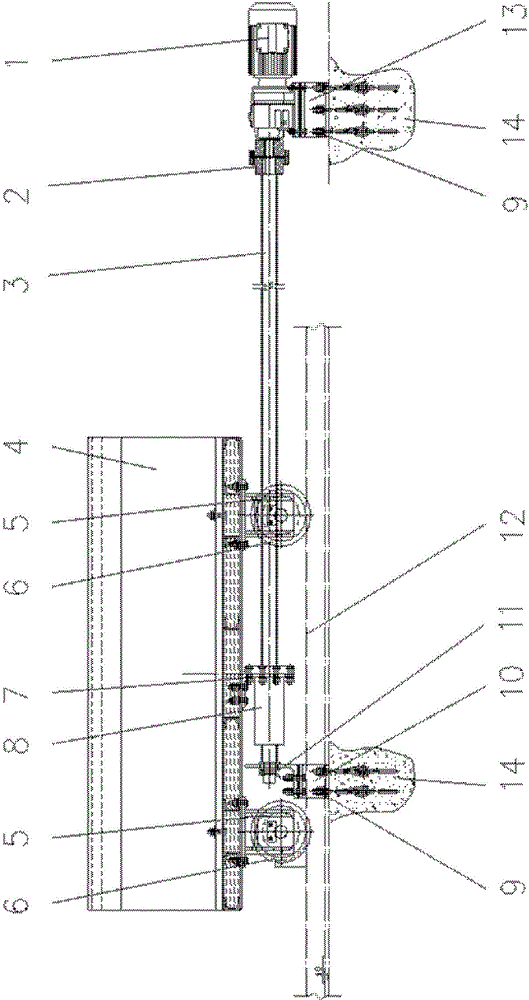

[0019] A trolley traction device, such as figure 1 As shown, it includes a motor 1, a coupling 2, a ball screw 3, a support frame 7, a ball screw pair 8, an anchor bolt 9, a fixed base 10, a support 11 and a motor support 13; the fixed base 10 passes through The anchor bolt 9 is fixed to the foundation 14 in the middle of the two parallel rails 12, the support 11 is fixed on the fixed base 10; the motor support 13 is fixed on the foundation 14 through the anchor bolt 9, and the motor 1 is fixed on the motor support 13 Above; the ball screw pair 8 is screwed on the ball screw 3 (the ball screw pair is equivalent to a nut), the right end of the ball screw 3 is connected with the output shaft of the motor 1 through the coupling 2, and the left end of the ball screw 3 is placed On the support 11 , the ball screw 3 is parallel to the rail 12 ; the ball screw pair 8 is fixedly connected to the bottom of the trolley frame 4 by the support frame 7 .

[0020] According to the above so...

Embodiment 2

[0024] A trolley traction device, such as figure 1 As shown, it includes a motor 1, a coupling 2, a ball screw 3, a support frame 7, a ball screw pair 8, an anchor bolt 9, a fixed base 10, a support 11 and a motor support 13; the fixed base 10 passes through The anchor bolt 9 is fixed to the foundation 14 in the middle of the two parallel rails 12, the support 11 is fixed on the fixed base 10; the motor support 13 is fixed on the foundation 14 through the anchor bolt 9, and the motor 1 is fixed on the motor support 13 Above; the ball screw pair 8 is screwed on the ball screw 3 (the ball screw pair is equivalent to a nut), the right end of the ball screw 3 is connected with the output shaft of the motor 1 through the coupling 2, and the left end of the ball screw 3 is placed On the support 11 , the ball screw 3 is parallel to the rail 12 ; the ball screw pair 8 is fixedly connected to the bottom of the trolley frame 4 by the support frame 7 .

[0025] According to the above sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com