Medium-high frequency electromagnetic induction heating fusion steel-plastic composite pipe connecting unit

A steel-plastic composite pipe, induction heating technology, applied in the direction of pipe connection layout, pipe/pipe joint/pipe fittings, mechanical equipment, etc., can solve the problem of electromagnetic induction non-response, weak response, etc., to achieve good sealing and pressure resistance Strong, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

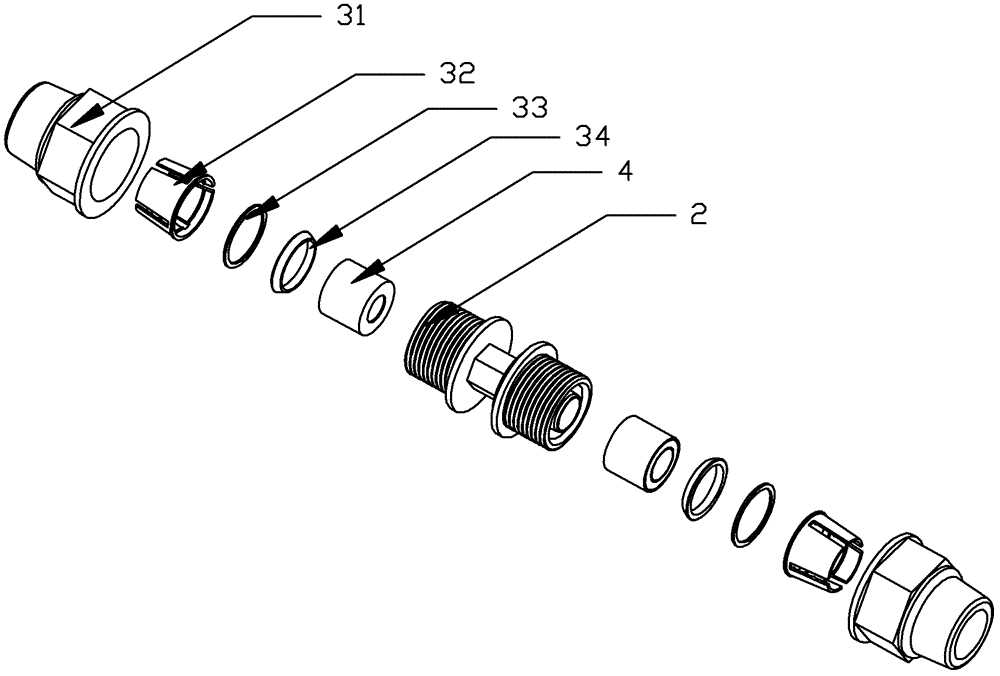

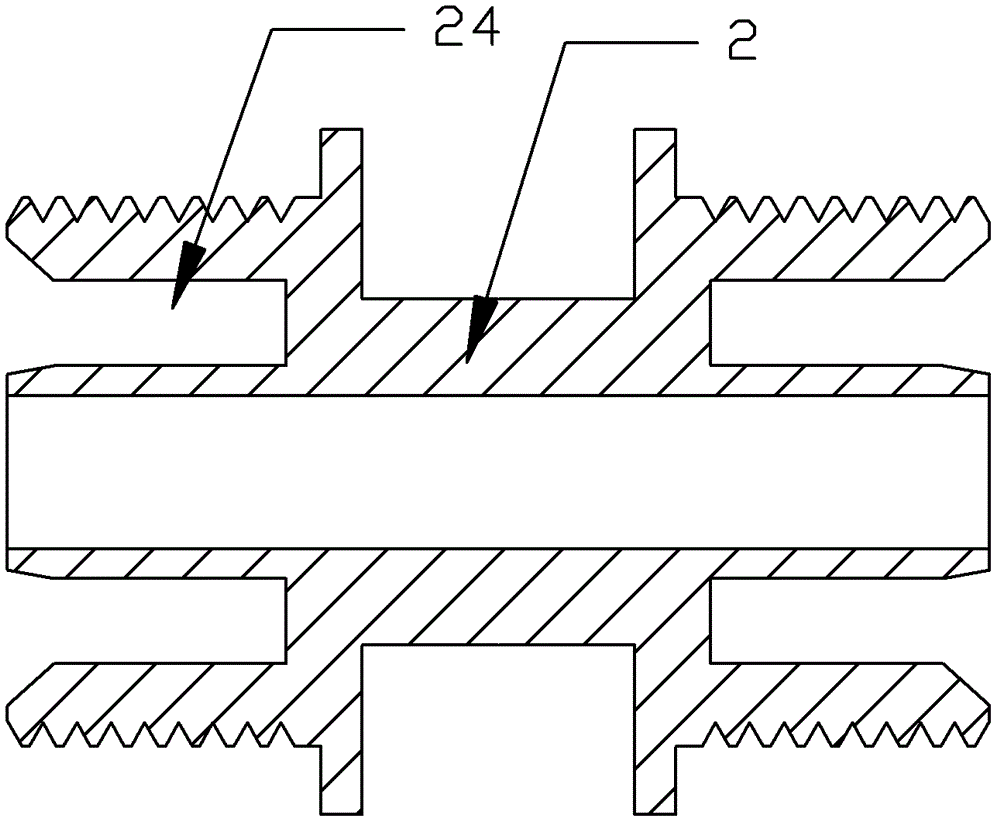

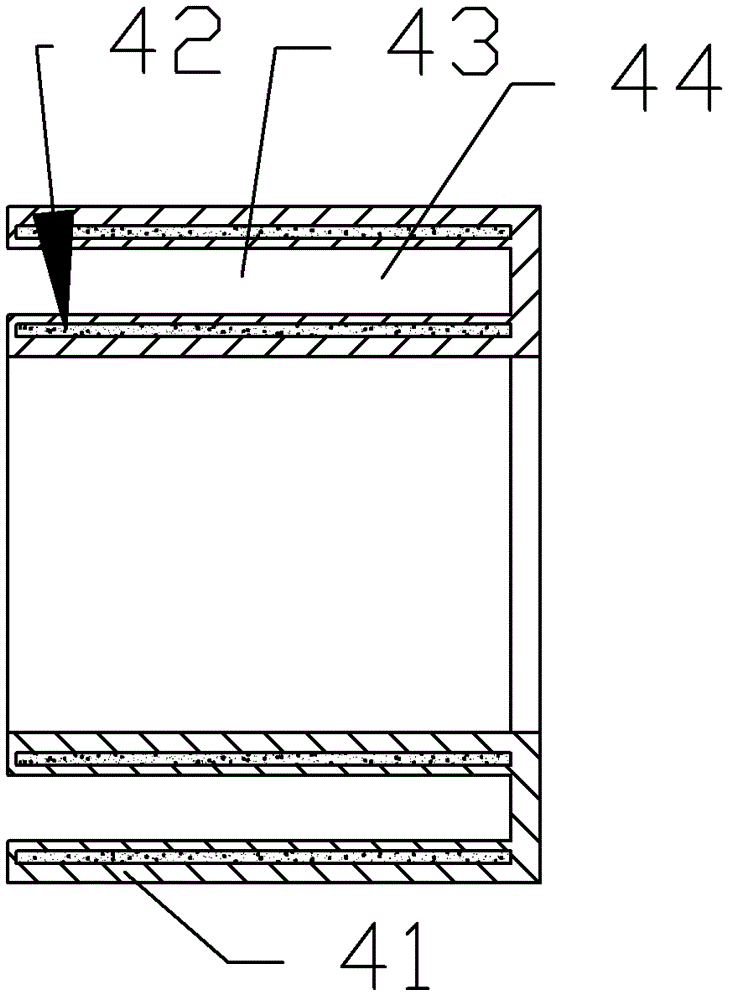

[0029] Such as figure 1 As shown, the medium-high frequency electromagnetic induction heating fusion steel-plastic composite pipe connection kit of the present invention includes: a composite pipe 1 , a connector 2 , a waterproof fastening component and a pipe sleeve 4 . The composite pipe 1 includes: a non-magnetic or weakly magnetically conductive metal layer 11 and a plastic layer 12, and the non-magnetically or weakly magnetically conductive metal layer 11 is 304 stainless steel, aluminum or aluminum alloy. Wherein, the non-magnetic or weakly magnetically permeable metal layer 11 is the outer layer, and the plastic layer 12 is the inner layer (such as Figure 8 shown); or the non-magnetic or weakly magnetically permea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com