Design method for hinge points of pullshovel working device of monobucket hydraulic excavator

A technology of hydraulic excavators and working devices, which is applied to mechanically driven excavators/dredgers, etc., and can solve problems such as not considering the influence of natural frequencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0145] Step 1. Selection of the size and pose of the working device of the original excavator:

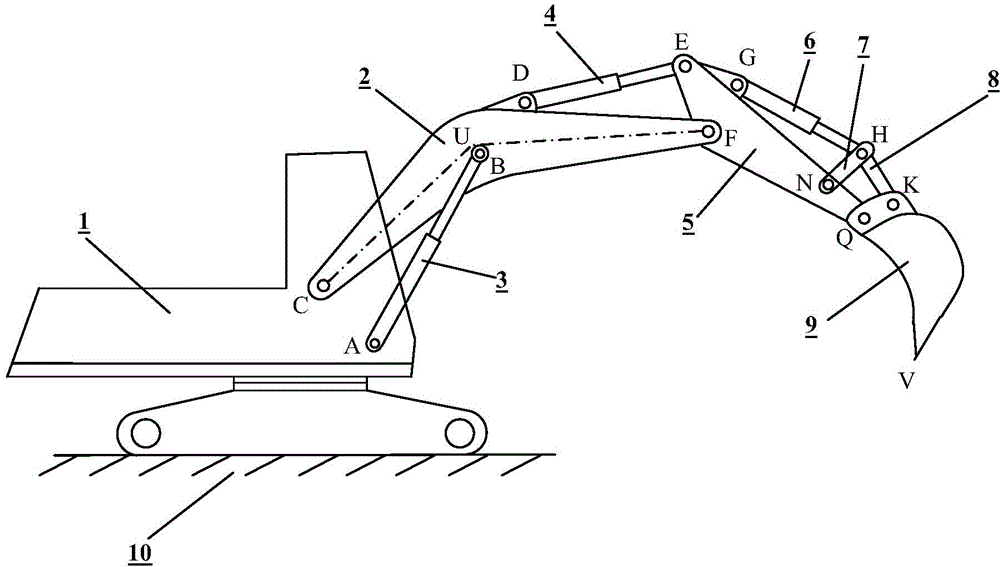

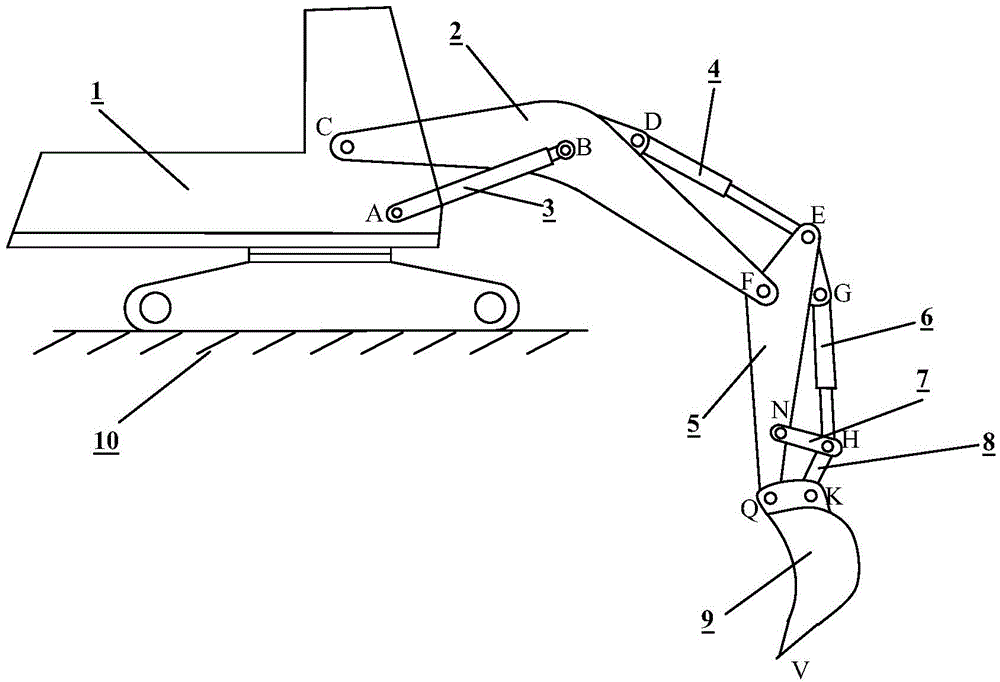

[0146] Taking a 30-ton excavator as the original excavator, select the maximum excavation depth of the excavator as the optimal design pose as follows: figure 2 shown.

[0147] Step 2. Establish an institutional model:

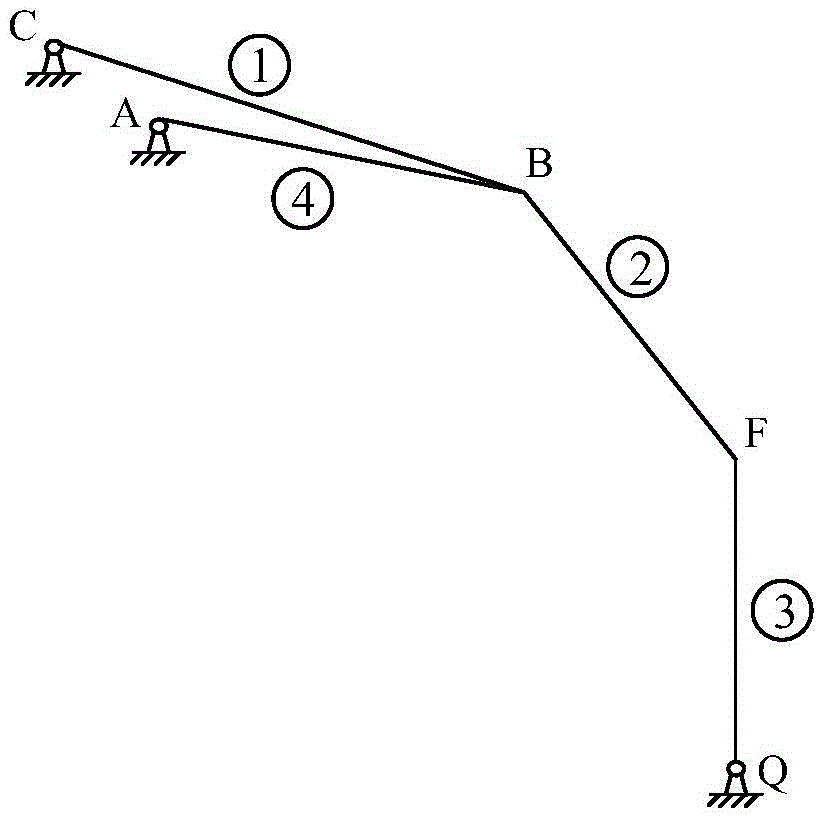

[0148] At the moment of excavation by the hydraulic excavator, the bucket and the ground are regarded as a fixed connection, and the fuselage is regarded as a fixed connection, then the three main components of the boom, arm and boom cylinder can be established image 3 Institutional model in;

[0149] Step 3: When the boom cylinder is fully retracted, it is equivalent to a rod of equal diameter:

[0150] In the software ANSYS, fix one end of the assembly when the boom cylinder is fully retracted, and apply an axial force F to the other end 1 and radial force F 2 ,F 1 is the maximum thrust of the oil cylinder, F 2 The linear distributed force is 1.6N / mm, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com