Ultra violet (UV) silk screen printing ink

A technology of screen printing inks and components, applied in inks, household appliances, applications, etc., can solve the problems of affecting the degree of resin curing, unable to achieve adhesion, difficult to UV curing, etc., to avoid blocking phenomenon, excellent weather resistance, The effect of reducing volume shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

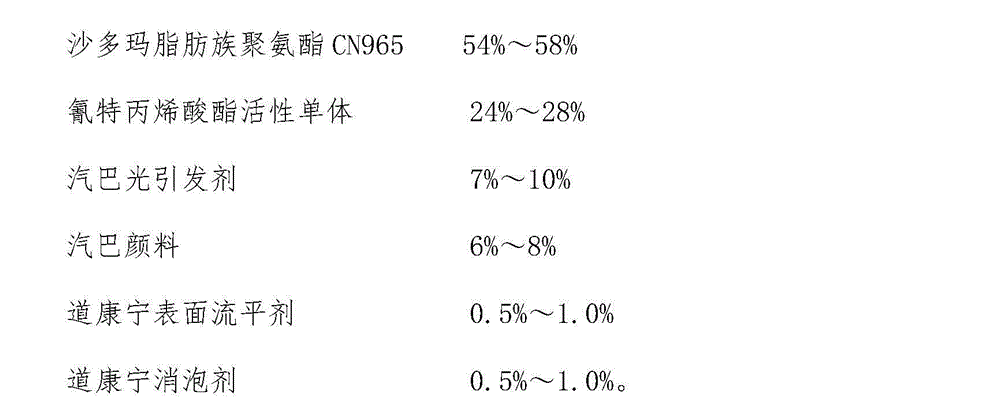

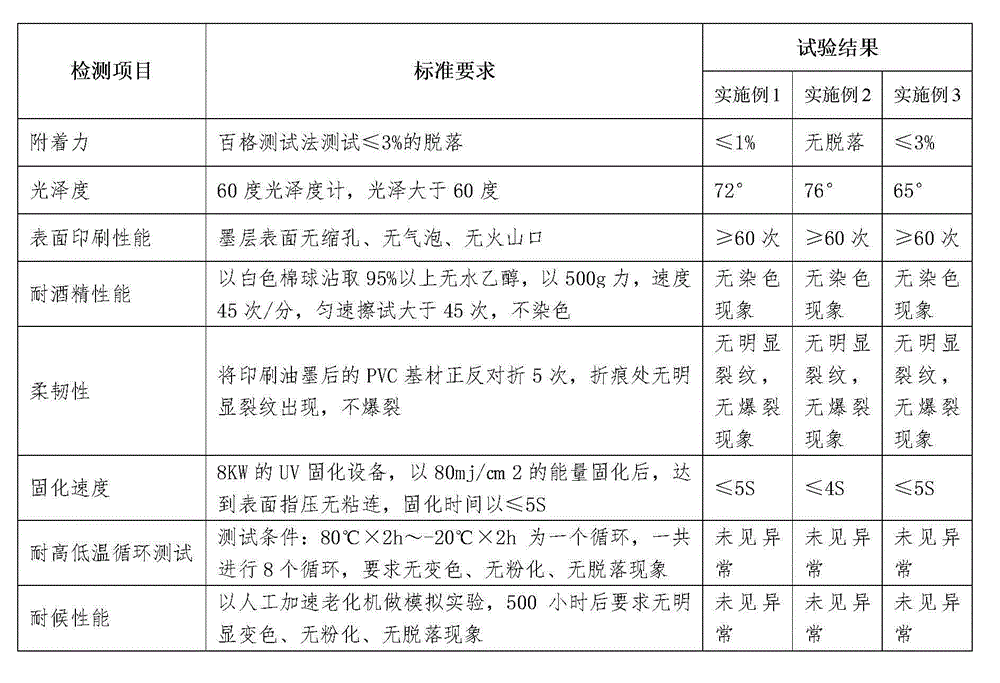

Embodiment 1

[0023] First, 580g of Sartomer aliphatic polyurethane, 260g of cytec reactive monomer (130g of propoxylated neopentyl glycol diacrylate and 130g of ethoxylated trimethylol propane triacrylate), Ciba photoinitiated Add 80g of Ciba pigment, 65g of Ciba pigment, 7g of Dow Corning surface leveling agent DC-27, and 8g of Dow Corning defoamer DC-163. After adding, disperse to 50°C with a mixer, and grind on a three-roller machine to a fineness ≤ 5um.

Embodiment 2

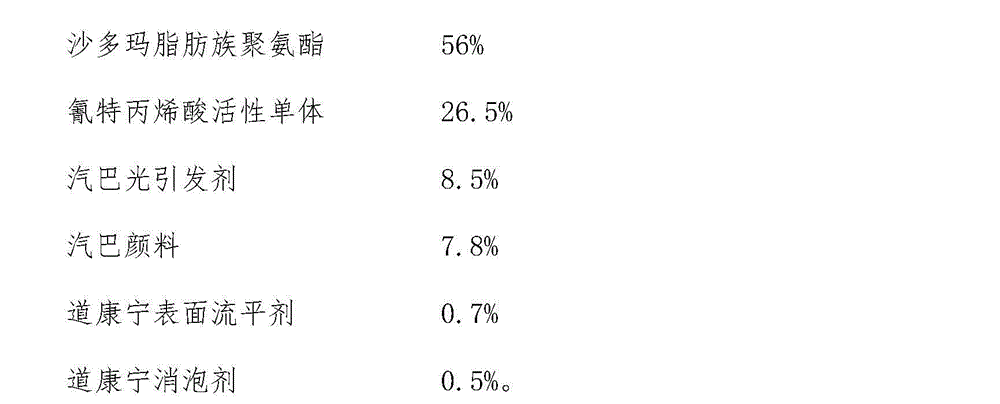

[0025] First, 560g of Sartomer aliphatic polyurethane, 270g of cytec reactive monomer (135g of propoxylated neopentyl glycol diacrylate and 135g of ethoxylated trimethylol propane triacrylate), Ciba photoinitiated Add 90g of Ciba Pigment, 65g of Ciba Pigment, 7g of Dow Corning Surface Leveling Agent DC-27, and 8g of Dow Corning Antifoaming Agent DC-163. After adding, disperse to 50°C with a mixer, and grind on a three-roller machine to a fineness ≤ 5um.

Embodiment 3

[0027] First, 540g of Sartomer aliphatic polyurethane, 280g of cytec reactive monomer (140g of propoxylated neopentyl glycol diacrylate and 140g of ethoxylated trimethylol propane triacrylate), and Ciba photoinitiated Add 90g of Ciba pigment, 70g of Ciba pigment, 10g of Dow Corning surface leveling agent DC-27, and 10g of Dow Corning defoamer DC-163. After adding, disperse to 50°C with a mixer, and grind on a three-roller machine to a fineness ≤ 5um.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com