A method for feeding and discharging materials in an aggregate transition bin and an aggregate transition bin for realizing the method

A technology for transitional bins, feeding and discharging materials, applied in the direction of sales of raw material supply devices, etc., can solve the problems of lower productivity of mixing stations, longer aggregate conveying cycle, etc., and achieve the effects of shortening mixing time, prolonging service life, and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better understand the technical solutions of the present invention, the embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

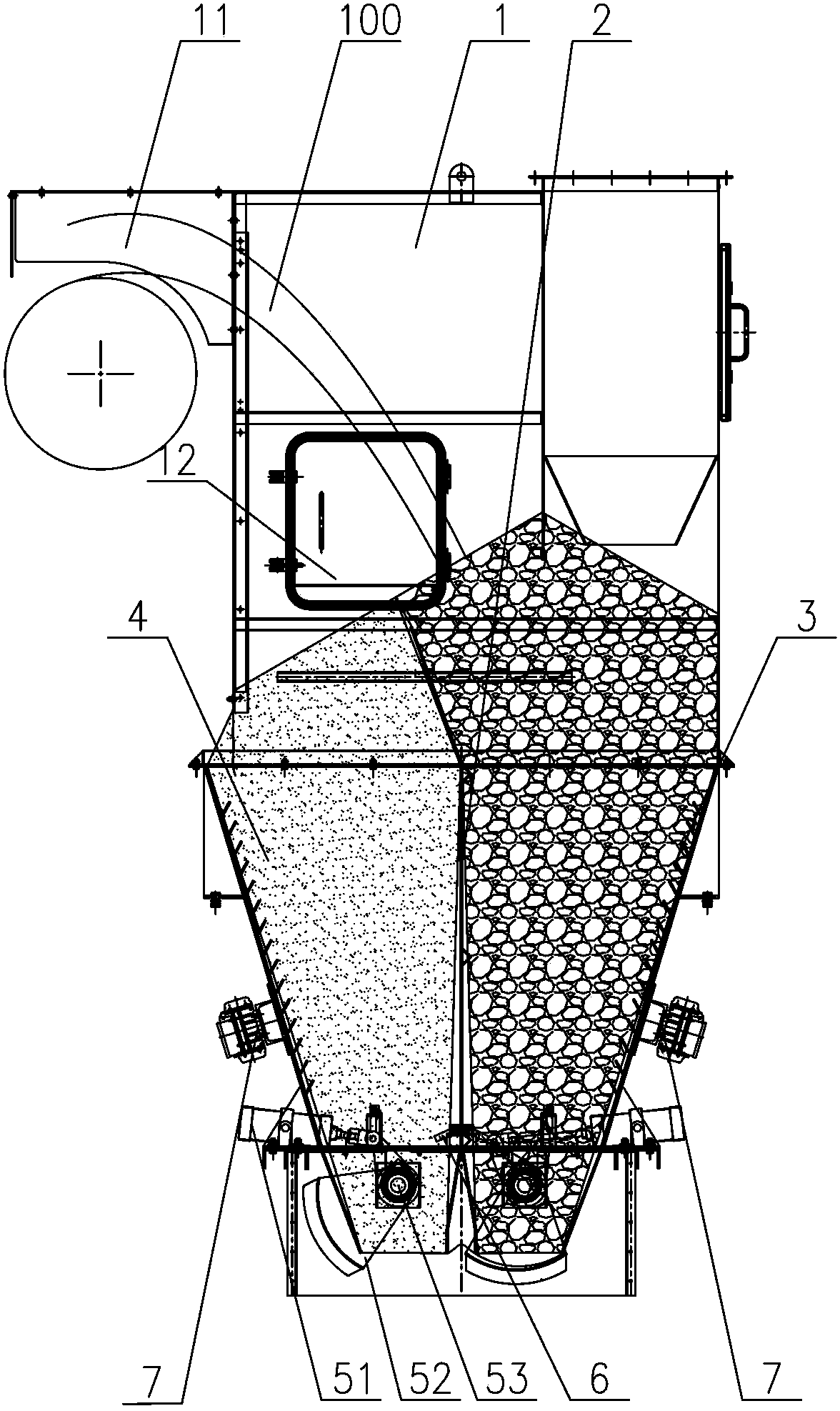

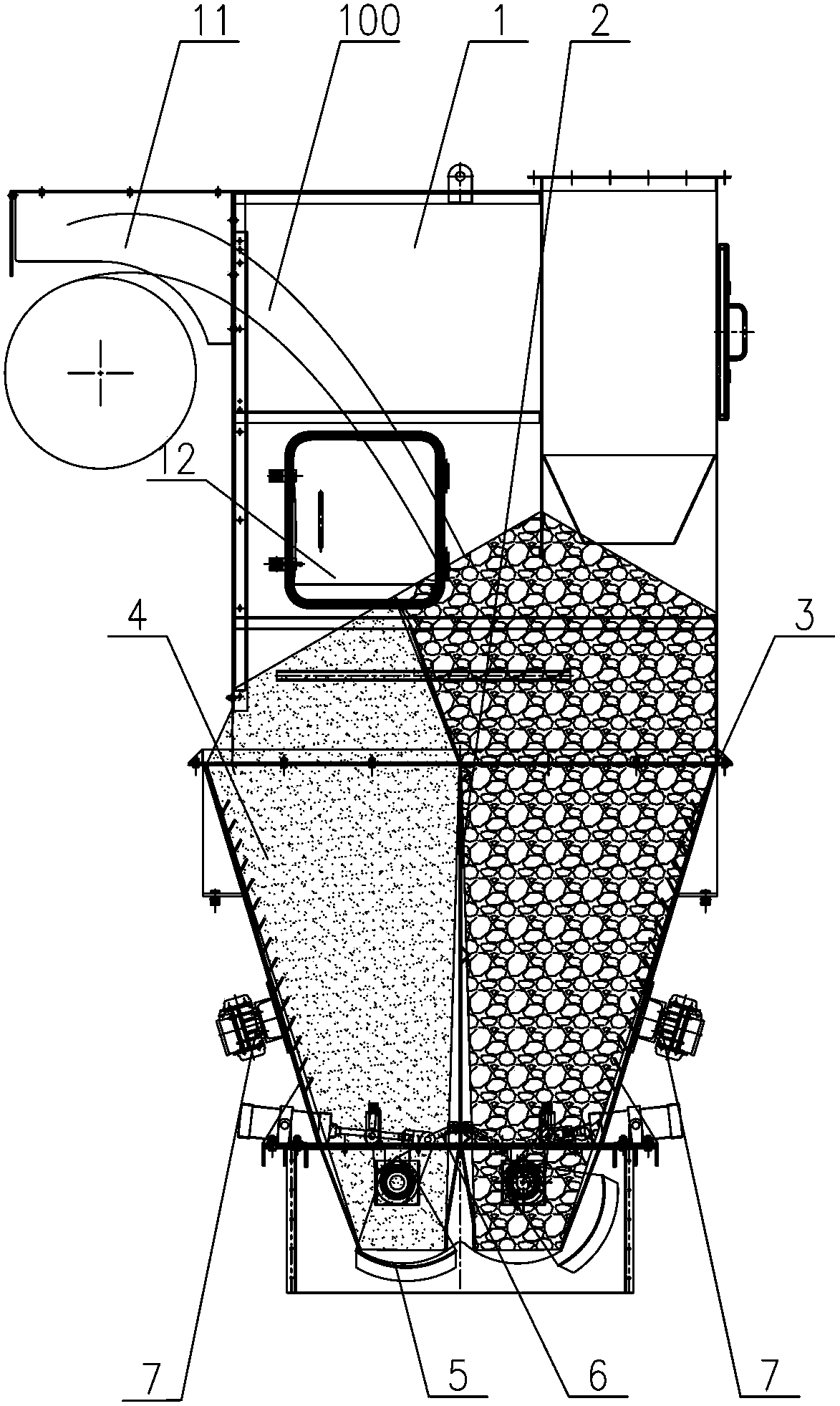

[0026] refer to figure 1 , figure 2 As shown, an aggregate transition bin includes an aggregate transition bin body 1 made of iron sheet material, and an aggregate transition bin body 1 is provided with a feed port 11 and an inspection door 12;

[0027] The aggregate transition bin body 1 is provided with a bin body partition 2, which divides the aggregate transition bin body 1 into a transition stone bin 3 and a transition sand bin according to the proportion of stones and sand required for mixing concrete. The bin 4 and the partition board 2 are divided into upper and lower parts, the lower part is vertically arranged in the aggregate transition bin body 1, and the upper part is inclined at a certain angle from the transition stone bin 3 to the transition s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com