Concrete pipe pile demoulding oil spraying device

A technology for concrete pipe piles and spraying devices, which is applied in the directions of spraying devices, ceramic molding machines, manufacturing tools, etc., can solve the problems of uneven spraying, low efficiency, affecting the demoulding of concrete pipe piles, etc., and achieves low working strength, Even spray effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

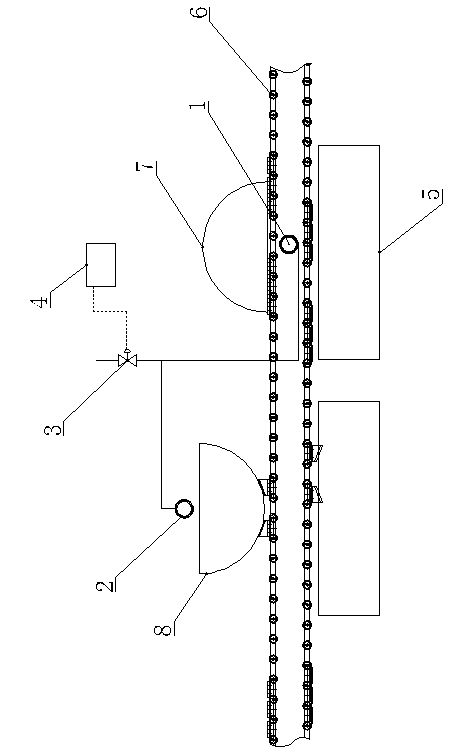

[0009] Such as figure 1 As shown, it includes a cover mold spray pipe 1, a bottom mold spray pipe 2, a solenoid valve 3, and a programmable controller 4.

[0010] The above-mentioned cover mold spray pipe 1 and bottom mold spray pipe 2 are staggered and arranged on the chain type concrete pipe pile mold conveyor 6. The distance between the upper cover mold and the bottom mold of the pile mold conveyor is the same. The height of the spray pipe 1 of the cover mold is slightly lower than the upper chain of the chain-type concrete pipe pile mold conveyor, and the spray pipe 2 of the bottom mold is slightly higher than that placed on the chain-type concrete pipe. Bottom form on pile mold conveyor.

[0011] On the top of the spray pipe 1 of the cover mold, there are a number of oil injection holes evenly distributed in a radial shape, and in the lower part of the spray pipe 2 of the bottom mold, there are a number of oil injection holes evenly distributed in a radial shape. The oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com