Active Control Magnetic Suspension Vibration Isolation Platform

A vibration isolation platform, active control technology, applied in the direction of magnetic attraction or thrust holding device, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

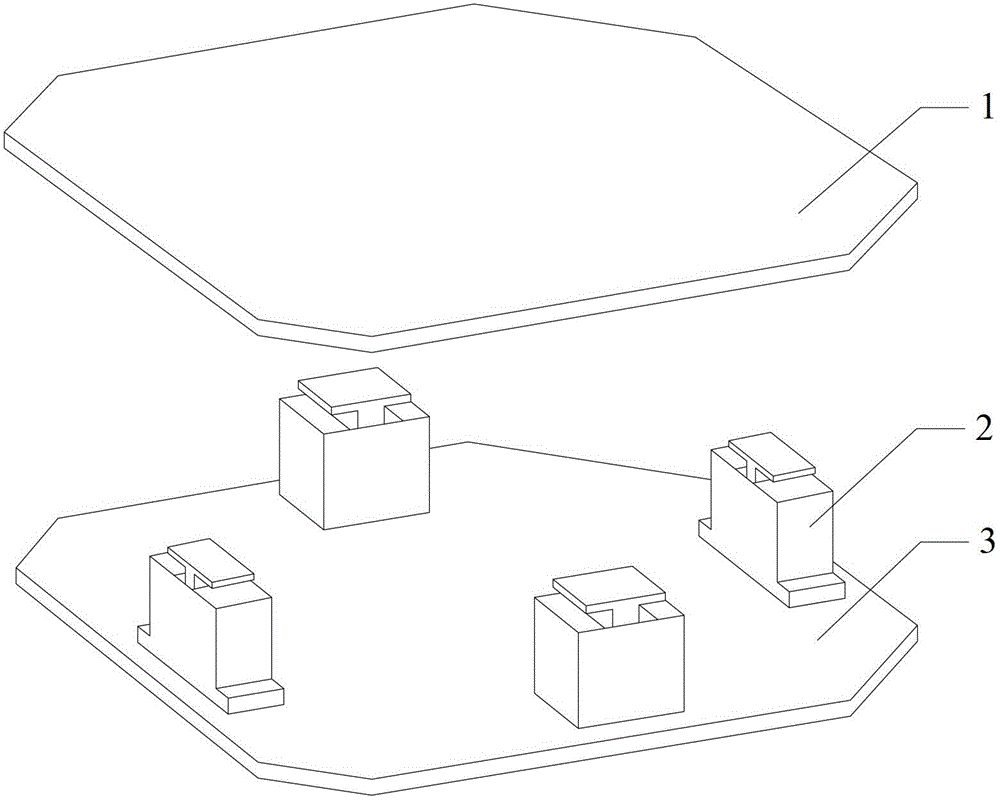

[0033] Embodiment 1: The active control type magnetic suspension vibration isolation platform described in this embodiment includes a moving base plate, a fixed base plate, four Z-direction load-bearing units and an adjustment unit; the four Z-direction load-bearing units and adjustment units are located between the moving base plate and the between the fixed base plates, and the line between the center of the quadrilateral formed by the four Z-direction load-bearing units and the adjustment unit and the center of the movable base plate is perpendicular to the plane where the movable base plate is located, and the Z-direction load-bearing and adjustment unit includes a Z-direction load-bearing unit and Z-direction adjustment unit,

[0034]Z-direction load-bearing unit includes stator permanent magnet 2c, stator permanent magnet fixing plate 2d, mover permanent magnet 2b and mover permanent magnet fixing plate 2a, stator permanent magnet 2c is fixed on the upper surface of stato...

Embodiment approach 2

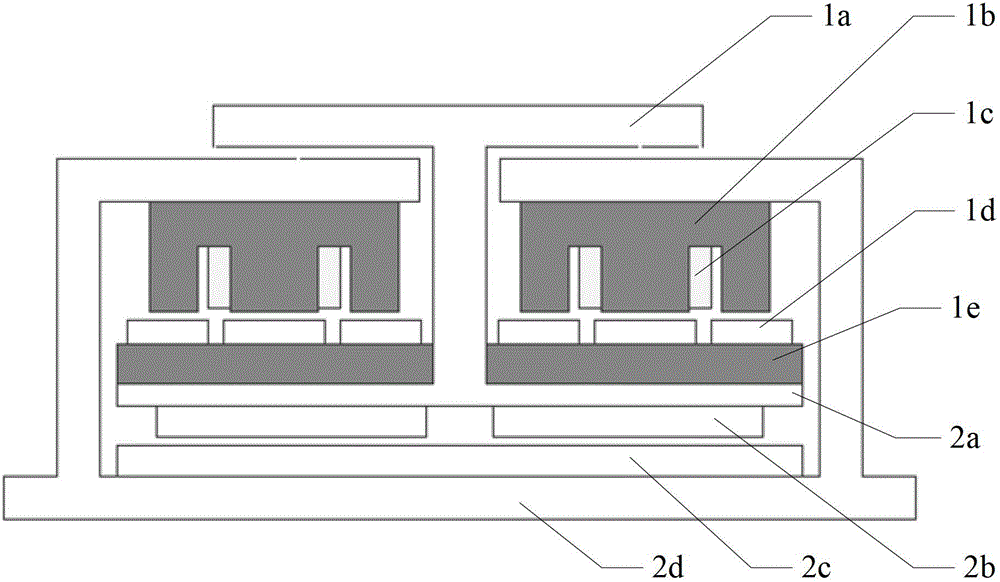

[0038] Embodiment 2: This embodiment is a further limitation on the structure of the Z-direction adjustment unit in the active control type magnetic suspension vibration isolation platform described in Embodiment 1. The primary stage of the Z-direction adjustment unit described in this embodiment includes a primary iron core 1b And the primary winding 1c, the primary iron core is an E-shaped iron core, the primary winding 1c is wound on the core column in the middle of the primary iron core; the secondary includes the secondary permanent magnet 1d and the secondary yoke plate 1e, and the secondary permanent magnet 1d is 3 pieces The flat-shaped permanent magnets magnetized in parallel in the vertical direction, the three flat-shaped permanent magnets correspond to the three core columns of the primary iron core respectively, and the three flat-shaped permanent magnets are pasted and fixed on the secondary yoke plate 1e, The magnetization direction of the flat permanent magnet l...

Embodiment approach 3

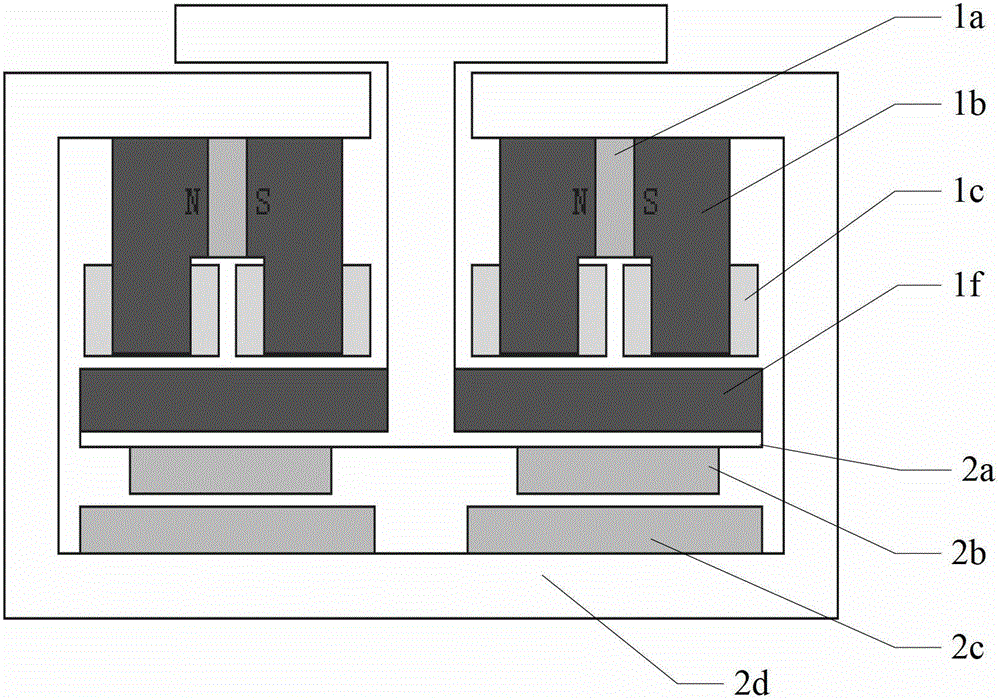

[0039] Embodiment 3: This embodiment is to further limit the structure of the Z-direction adjustment unit in the active control type magnetic suspension vibration isolation platform described in Embodiment 1. The primary iron core 1b, primary Winding 1c and primary permanent magnet 1a, the primary iron core 2b is composed of two Γ-shaped iron cores, the primary permanent magnet 1a is a flat plate, fixed in the middle of the horizontal section of the two Γ-shaped iron cores; the primary winding 1c is composed of two coils, two The two coils are respectively wound on the two vertical core posts of the Γ-shaped iron core; the secondary is the high magnetic permeability metal plate 1f.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com