Novel series excited machine double-insulation structure

A series excitation motor and insulation structure technology, applied in the direction of electrical components, electromechanical devices, DC commutators, etc., can solve the problems of unreliability, difficulty in detection, increased difficulty of production management, and smog environmental pollution, etc., to achieve improved The effect of motor performance and product consistency, small beating, and low overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

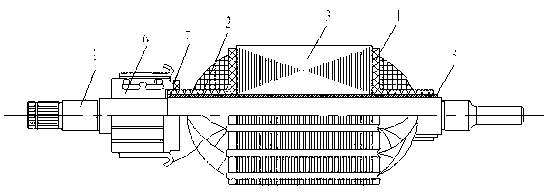

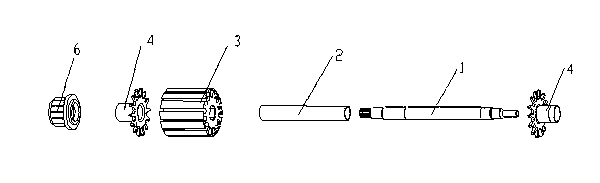

[0020] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0021] see figure 1 with figure 2 , the embodiment of the present invention includes:

[0022] A new double insulation structure of a series motor, comprising: a rotating shaft 1, an insulating sleeve 2, and an iron core 3, the insulating sleeve 2 is coaxially assembled in the inner hole of the iron core 3, and the rotating shaft 1 is coaxially arranged in the insulating sleeve 2. The two ends of the iron core 3 are respectively equipped with insulating end plates 4 .

[0023] Wherein the insulating sleeve 2 is an insulating sleeve 2 made of glass fiber and resin. The insulating sleeve 2 is a grinding part with small runout and high precisio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com