Analog control rod assembly of nuclear power station

A technology for analog control and nuclear power plants, applied in nuclear power generation, nuclear engineering, nuclear reactor monitoring, etc., can solve problems such as inaccurate results of friction tests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

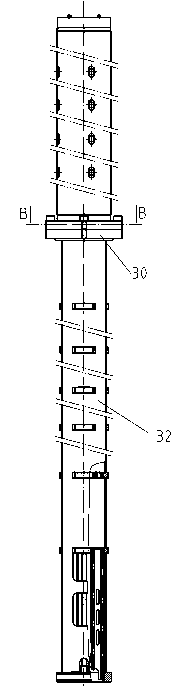

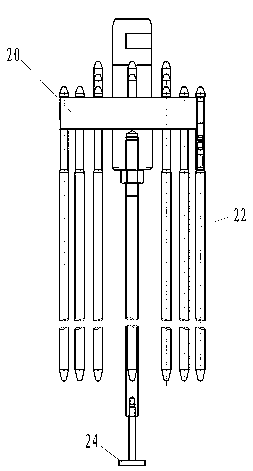

[0019] see image 3 with Figure 4 , The simulated control rod assembly of the nuclear power plant of the present invention includes a spider 20 , a simulated control rod 22 and a weight suspension rod 24 .

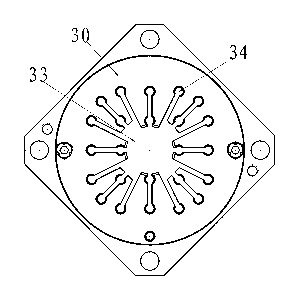

[0020] The spider 20 is provided with simulated control rod fixing holes 200. However, the centers of these fixing holes 200 are not aligned with the theoretical centers of the corresponding guide holes 34 of the control rod guide cylinder, but are offset by 0.1~0.5mm, and different The offset direction of the fixed hole 200 relative to the theoretical center of the corresponding guide hole 34 is different, and the specific offset direction is as follows: Figure 4 indicated by the arrows in each. The optimum offset of the center of each fixing hole 200 is 0.1mm.

[0021] The outer diameter of the simulated control rod is 0.1~0.5mm smaller than the existing technology, that is, it is 0.2~1.0mm smaller than the diameter of the guide hole of the control rod guide cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com