Opto-electric hybrid board and manufacturing method therefor

A technology of optoelectronic hybrid substrate and manufacturing method, applied in final product manufacturing, sustainable manufacturing/processing, optics, etc., can solve problems such as increased cost, time-consuming and labor-intensive, and poor alignment accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

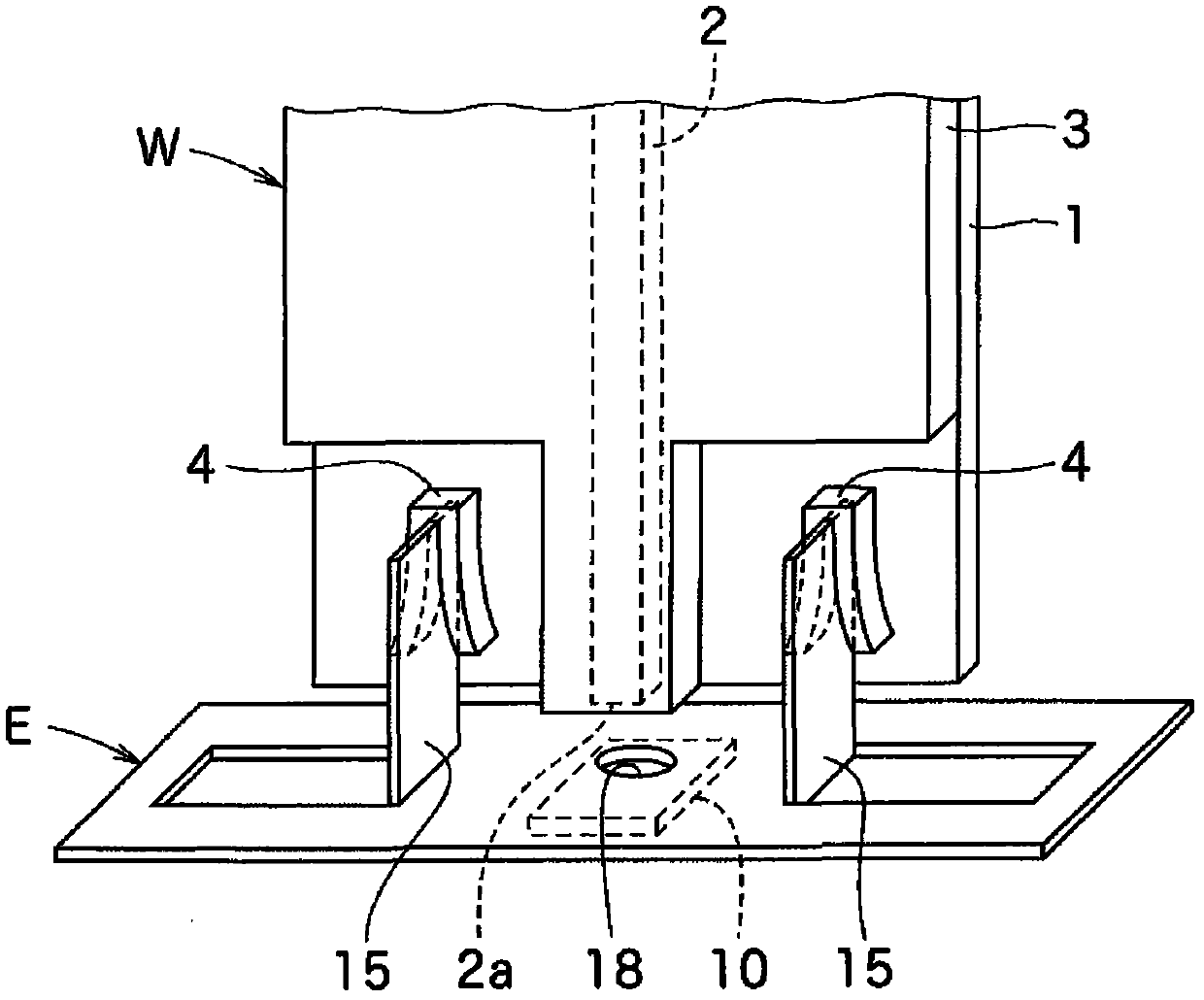

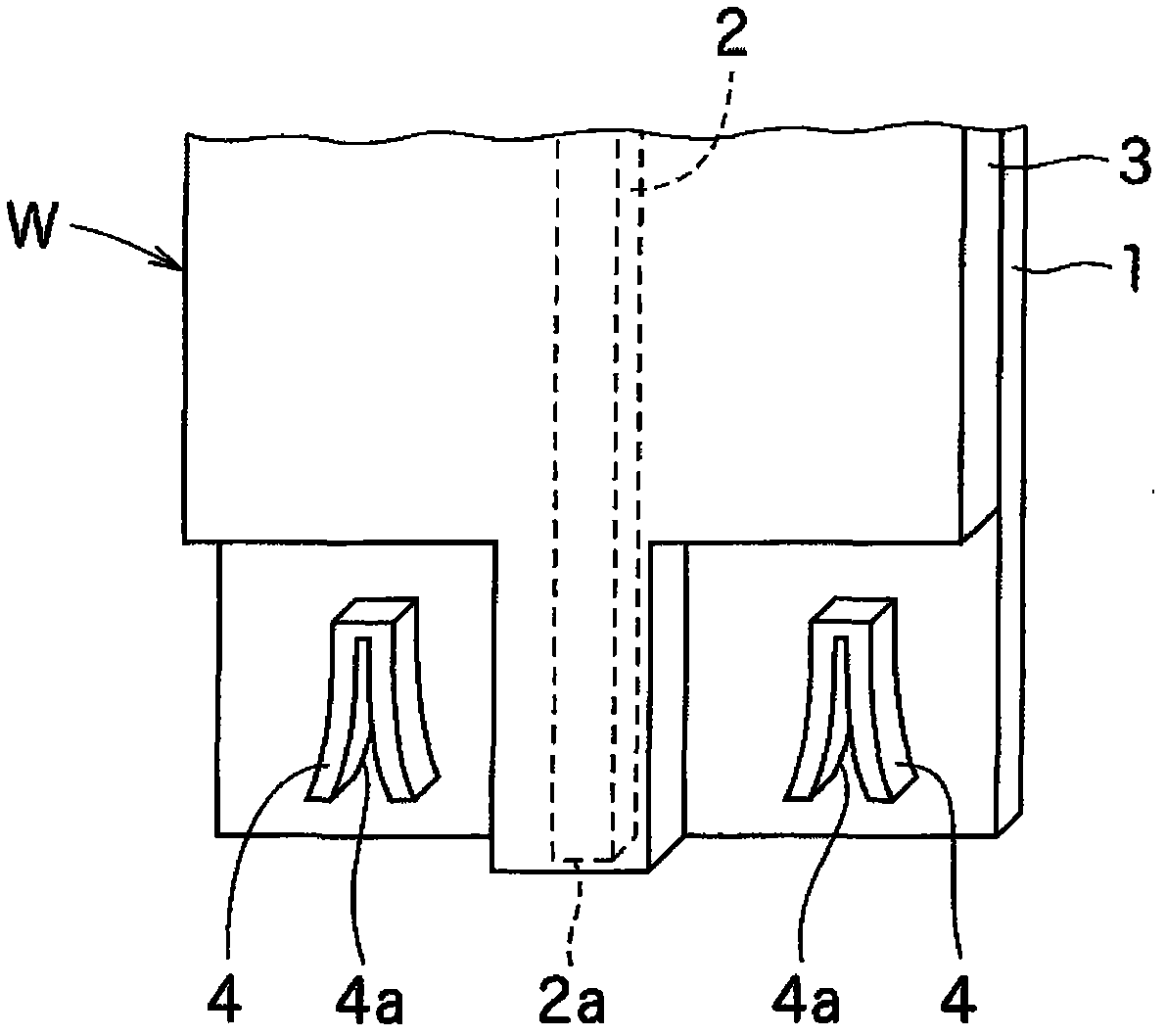

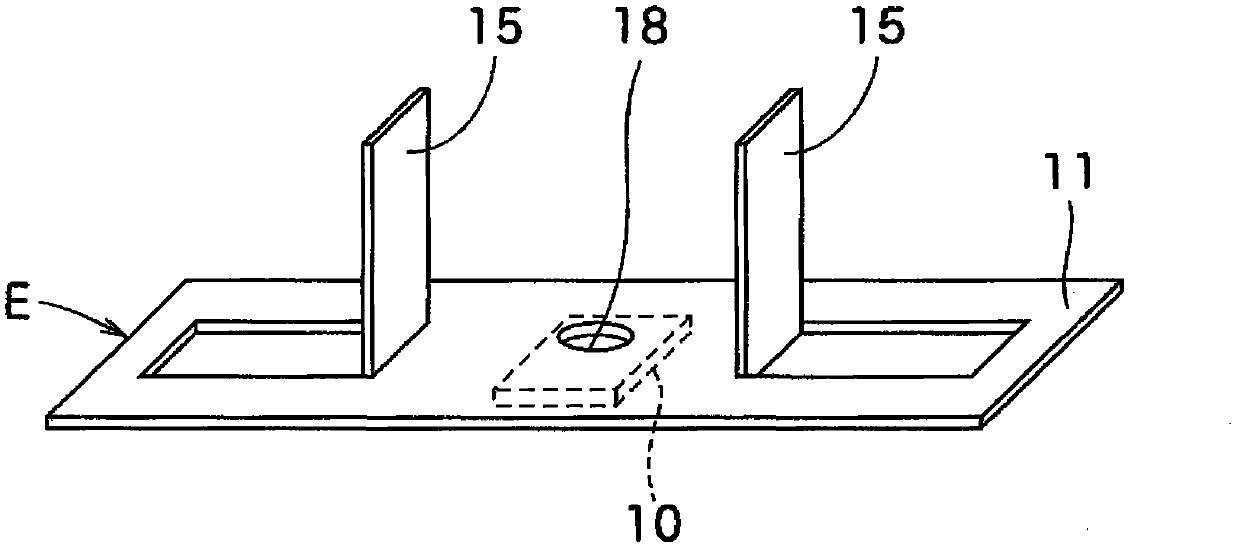

[0076] Fabrication of Optical Waveguide Units

[0077] Using each of the above-mentioned materials for forming the lower cladding layer, core, and upper cladding layer, in order to be compatible with the above-mentioned figure 1 An optical waveguide unit having a V-shaped insertion portion for positioning a circuit unit was manufactured in the same manner as the illustrated embodiment. The dimension of the above-mentioned V-shaped insertion part is 1.98 mm in depth, the minimum width of the inner side of the V-shape is 80 μm, the maximum width of the opening side of the V-shaped opening is 820 μm, and the center of the adjacent insertion part The distance between them is 6.0mm.

[0078] Fabrication of circuit units

[0079] with the above figure 1 A circuit unit having a rectangular bent portion that fits into the insertion portion for positioning the circuit unit described above was fabricated by the same method as in the illustrated embodiment. The dimensions of the ...

Embodiment 2

[0083] Fabrication of Optical Waveguide Units

[0084] One end of the optical waveguide unit of Embodiment 1 described above and Figure 9 of (a), Figure 9 The embodiment shown in (b) is similarly formed as an inclined surface. The other parts are the same as in the above-mentioned Example 1.

[0085] Fabrication of circuit units

[0086] The circuit unit of Embodiment 1 described above was prepared.

[0087] Manufacture of photoelectric hybrid substrate

[0088] The optical waveguide unit and the circuit unit are integrated by fitting the bent portion of the circuit unit into the insertion portion of the optical waveguide unit with the optical waveguide unit parallel to the circuit unit. Then, the fitting portion is fixed with an adhesive.

[0089] light propagation test

[0090] Electricity was supplied to the light-emitting elements of the photoelectric hybrid substrates of Examples 1 and 2 above to emit light from the light-emitting elements. Then, it was ...

Embodiment 3

[0092] Fabrication of Optical Waveguide Units

[0093] In addition to the optical waveguide unit of the above-mentioned first embodiment, the other end portion is also an optical waveguide unit having a V-shaped insertion portion for positioning the circuit unit in the same manner as the one end portion. The other parts are the same as in the above-mentioned Example 1.

[0094] Fabrication of circuit units

[0095] The same circuit unit as in Embodiment 1 above was produced. Furthermore, a circuit unit in which a flip-chip type light-receiving element (manufactured by Albis Corporation, PDCA04-70-GS) was mounted instead of the light-emitting element in the circuit unit of Example 1 was produced.

[0096] Manufacture of photoelectric hybrid substrate

[0097] In the same manner as in the first embodiment, the circuit unit of the light-emitting element was fixed to one end of the optical waveguide unit, and the circuit unit of the light-receiving element was fixed to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com