Crab-claw type filling device for filling slag into mine blast holes

A blast hole and crab pincer technology, which is applied in the field of crab pincer packing devices, can solve the problems of not being able to better adapt to the filling operation of circular slag piles, easy damage to the detonator detonator or foot line, and large resistance, so as to improve Safety reliability and blasting quality, simple and practical design, and the effect of reducing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

[0021] Such as figure 1 , 2 , shown in 3, a kind of crab pincer packing device that is used for mine blasthole slag filling is characterized in that a scraper device is provided at the front of the driving vehicle, and a blasthole filling auxiliary protection device is provided in the slag filling blasthole , the scraper device is composed of a support 1 fixed at the front of the driving vehicle, and a double-arm crab-claw funnel-type scraper hinged to the middle of the support 1 and connected to a hydraulic drive system.

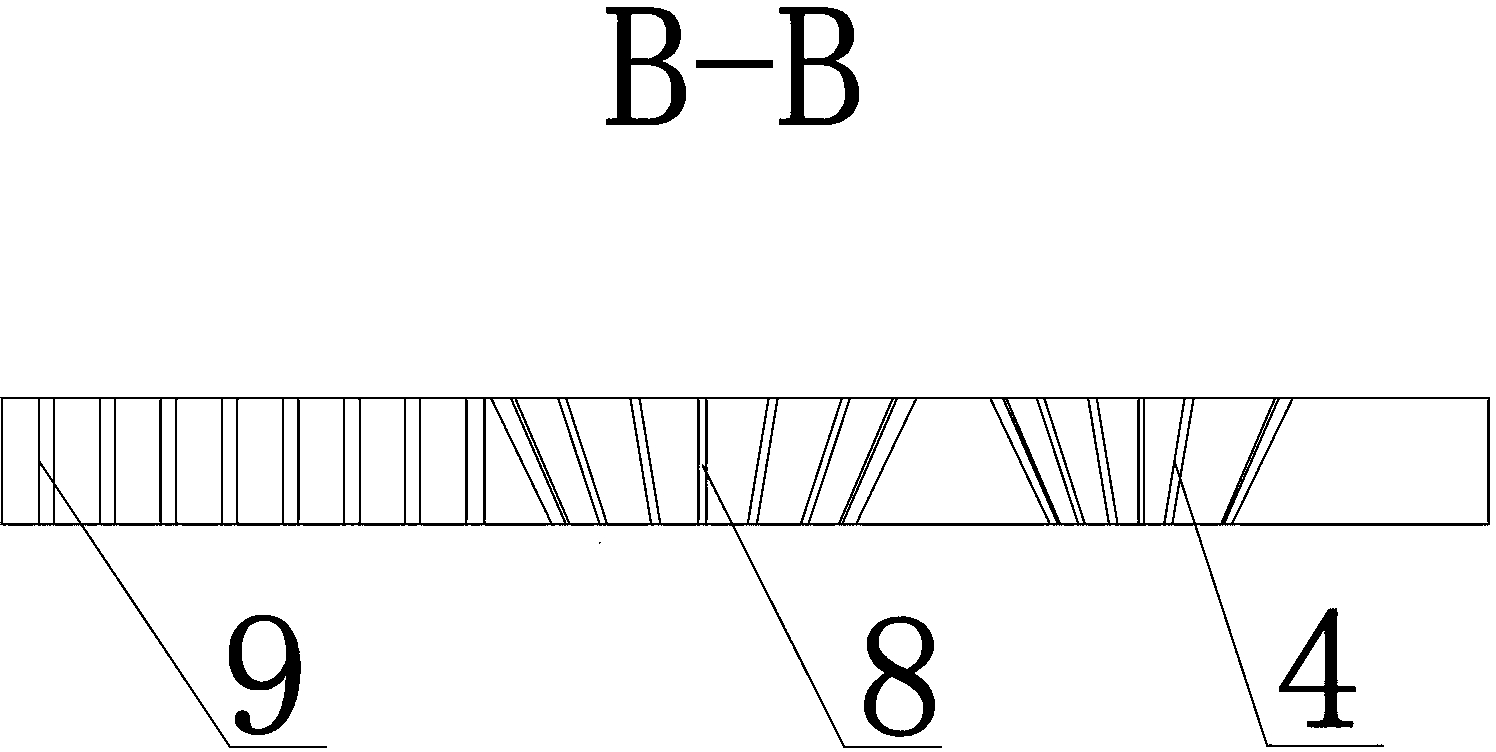

[0022] The crab claw scraper with two arms is hinged by two symmetrically arranged crab claw scrapers 3. The front part of the crab claw scraper 3 is provided with a crushing jaw 6, and the jaw opening of the crushing jaw 6 is A group of occlusal teeth III9 are provided, and the middle and tail parts of the cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com