Bolt having a rotation preventing mechanism

A rotating mechanism and anti-rotation technology, which is applied in the direction of bolts, screws, nuts, etc., can solve the problems of slow loosening of bolts and nuts and the inability to maintain fastening force for a long time, and achieve the effect of maintaining fastening force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

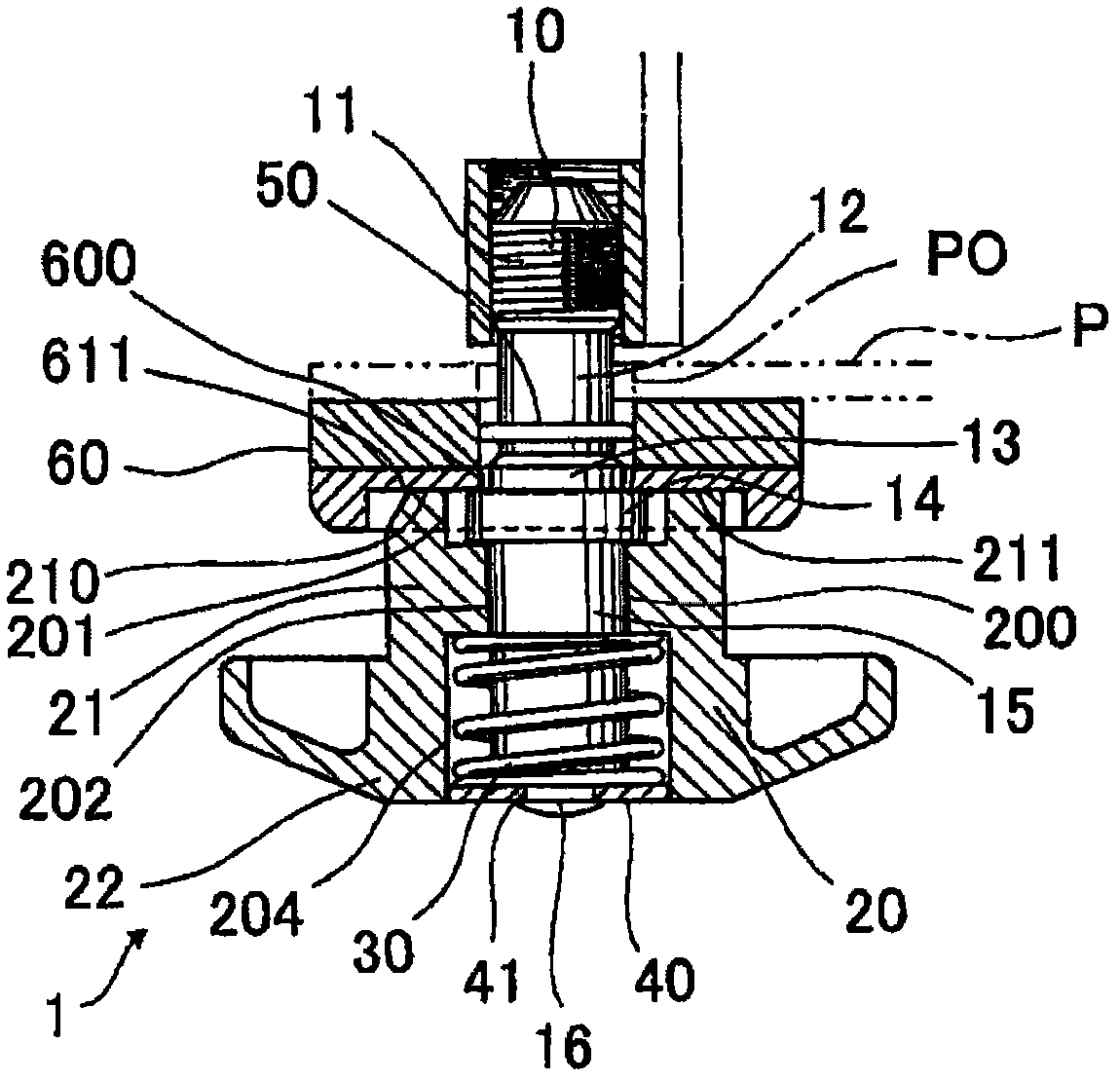

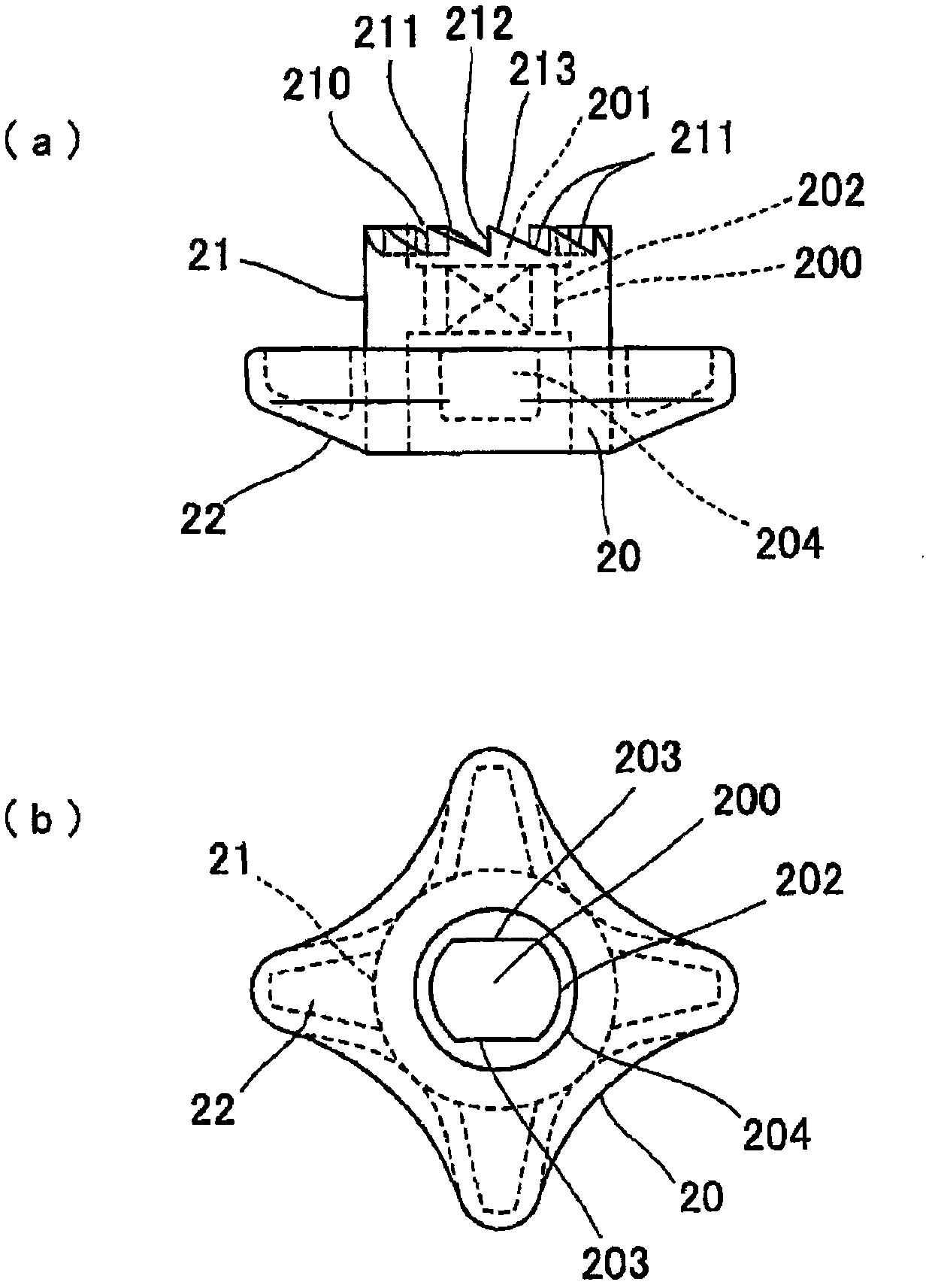

[0070] Next, embodiments of the present invention will be described with reference to the drawings. figure 1 shows the bolt 1 with anti-rotation mechanism. The bolt 1 with anti-rotation mechanism includes: a shaft part 10 having a male thread 11 on the front end side of the shaft part 10; There are teeth 211 on the periphery of the shaft portion 10 and on the joint surface 210 opposite to the periphery of the bolt insertion hole P0 provided on the fastened part P; a spring device 30 that faces the head 20 toward Press and apply force around the bolt insertion hole P0 of the fastened part P; around the hole P0 and has teeth 611 capable of meshing with the teeth 211 of the head 20 .

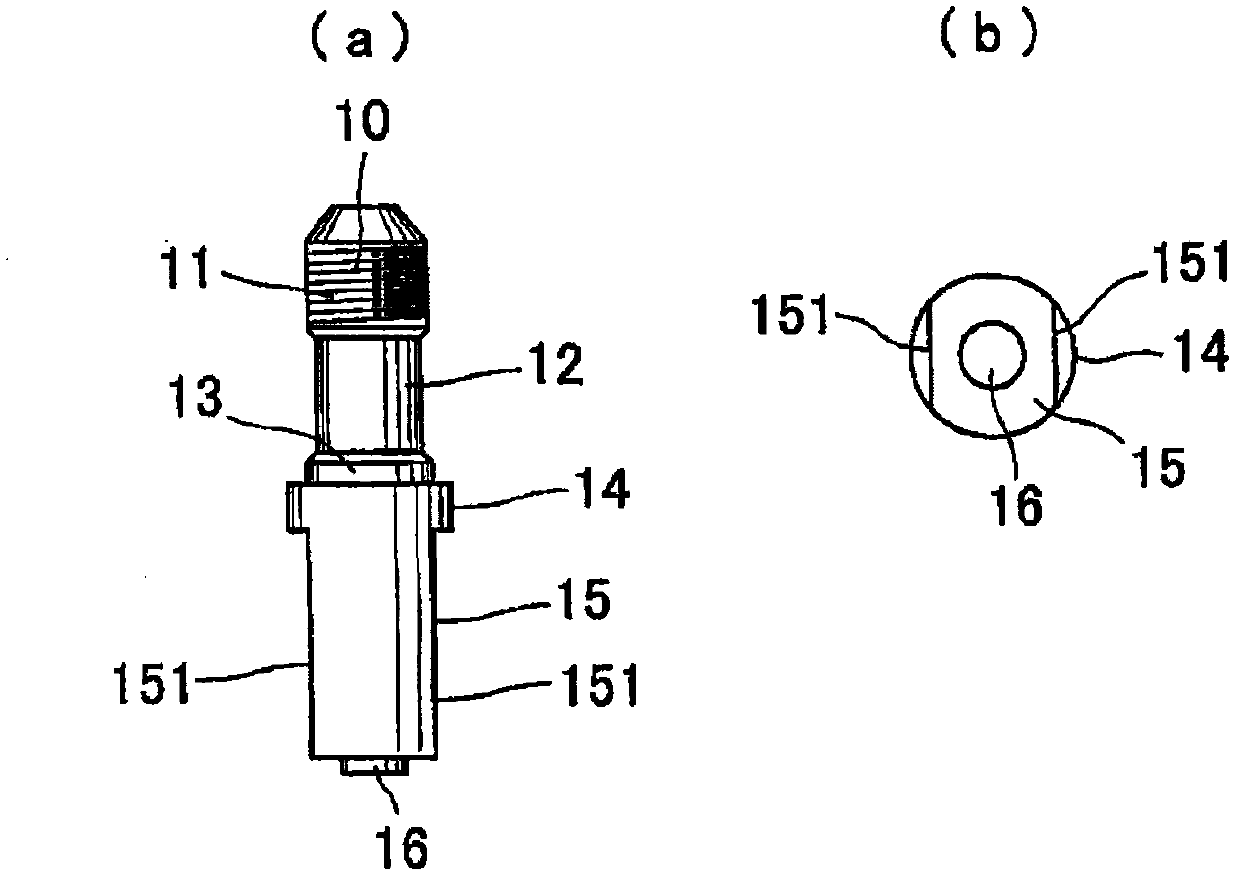

[0071] figure 2 The middle indicates the shaft portion 10 . Such as figure 2 As shown, the shaft portion 10 is made of metal materials such as stainless steel, and has an approximate cylindrical shape as a whole. A male thread 11 is formed on the front end side of its outer peripheral surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com