Compressor

A compressor and cylinder technology, applied in the mechanical field of compressed gas, can solve the problem that a piston gas compressor cannot use surplus compressed gas to assist power, etc., and achieve the effects of reducing friction loss, reducing temperature rise, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

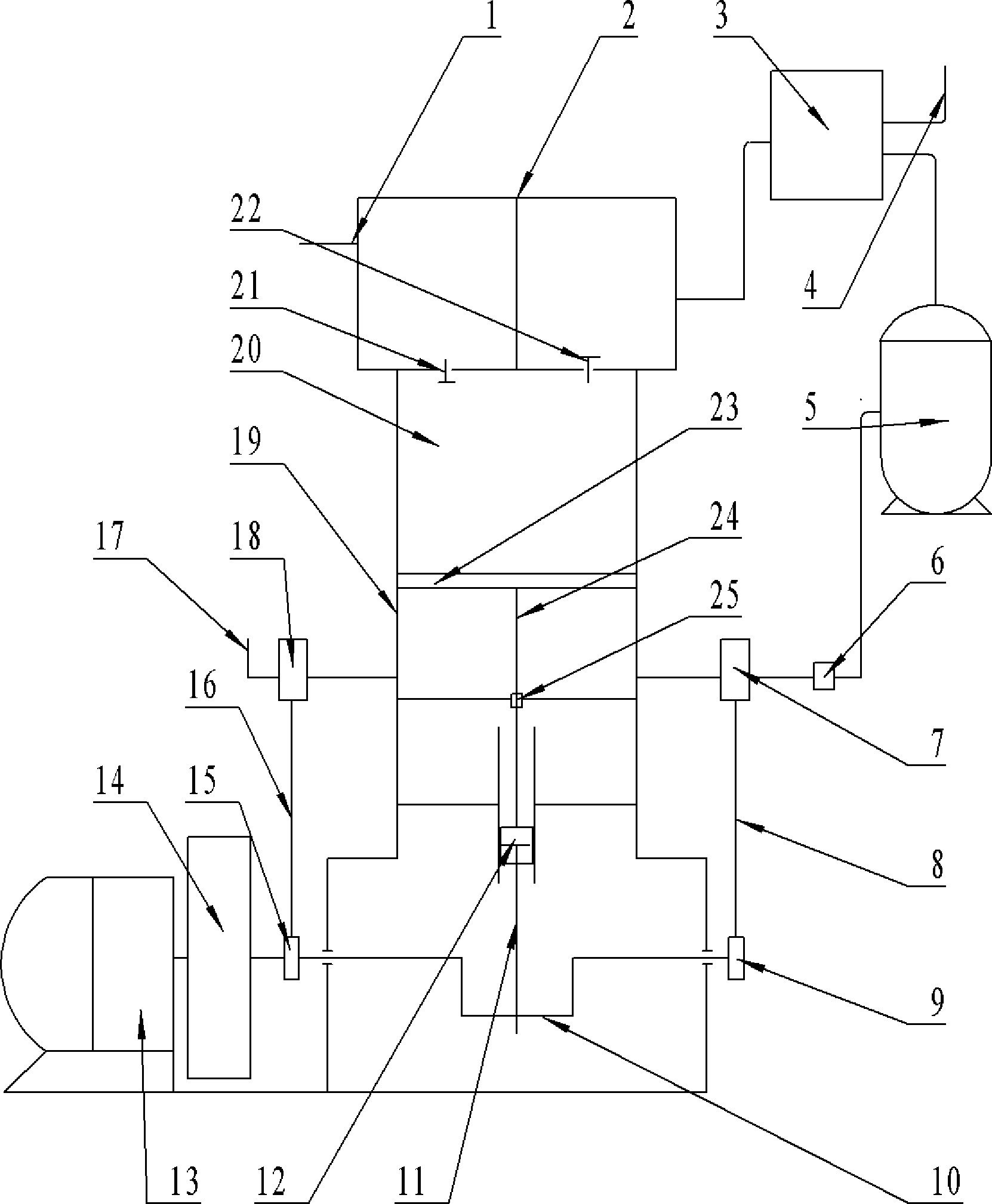

[0014] figure 1 Shown is a schematic diagram of the working principle in which the industrial gas is first compressed by the compressor and then separated, and then the excess compressed gas is returned to the compressor to assist in the compression of the industrial gas. The industrial gas enters the compressor cylinder 20 from the compressor inlet 1, and enters the gas separator 3 for separation after being compressed by the compressor. After the separated useful gas is output from the air pipe 4, other compressed gases enter the gas storage tank 5 become surplus compressed gas.

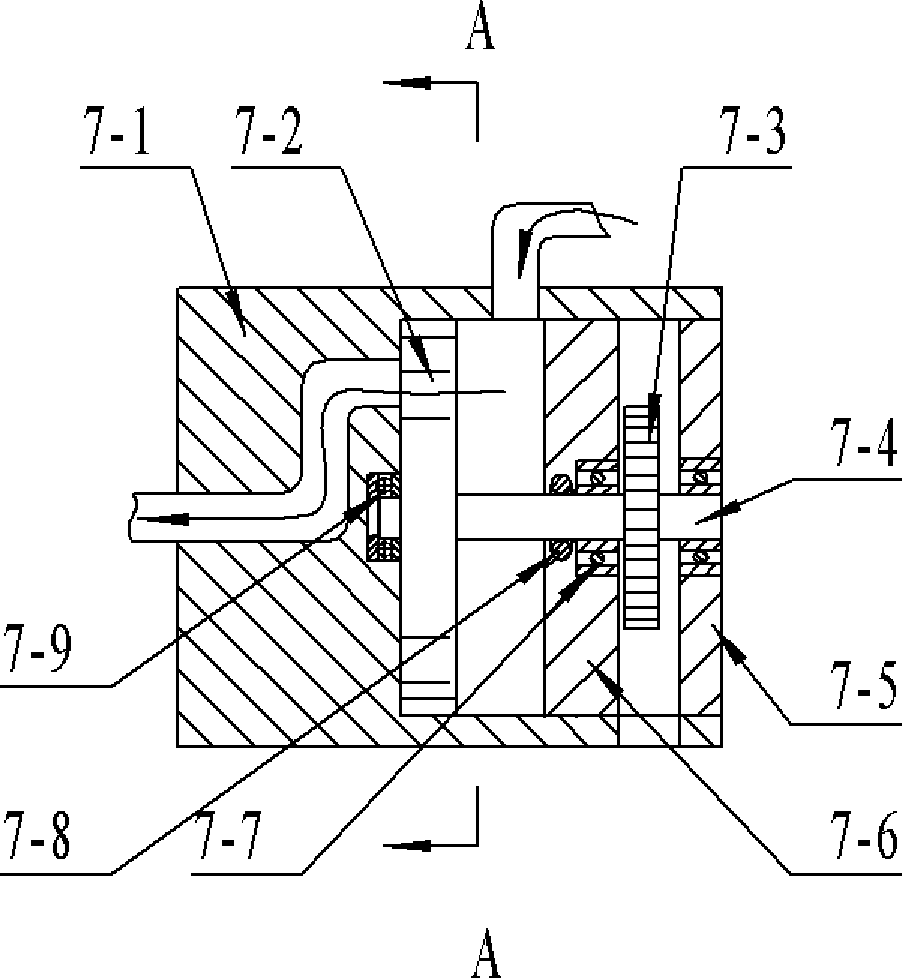

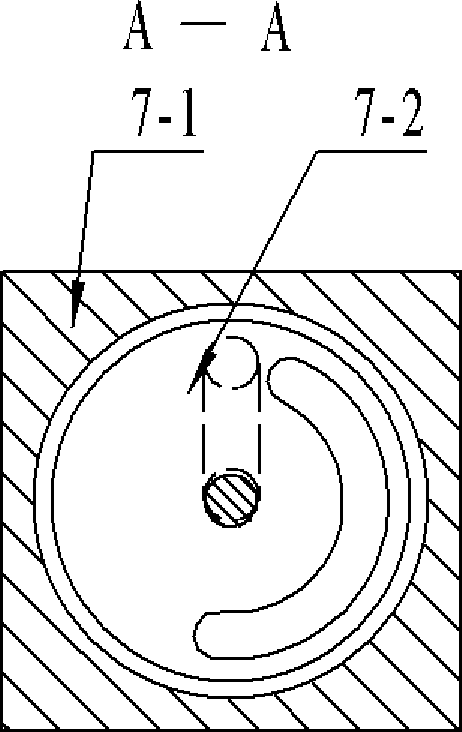

[0015] figure 1 The compressor in, has a valve body 2 that contains intake valve 21 and exhaust valve 22, has a fuselage 19 that is provided with cylinder 20 in, and valve body 2 is contained in the upper end of fuselage 19. Piston 23 is housed in cylinder 20, and the lower end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com