Hydraulic control system for coal pickup manipulator and working method

A technology of hydraulic control system and manipulator, applied in mechanical equipment, earth-moving drilling, fluid pressure actuating device, etc., can solve the problems of low work efficiency, high labor intensity, short work space, etc., so as to improve work efficiency and reduce labor the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] specific implementation

[0040] Embodiments of the present invention will be further described below according to the accompanying drawings.

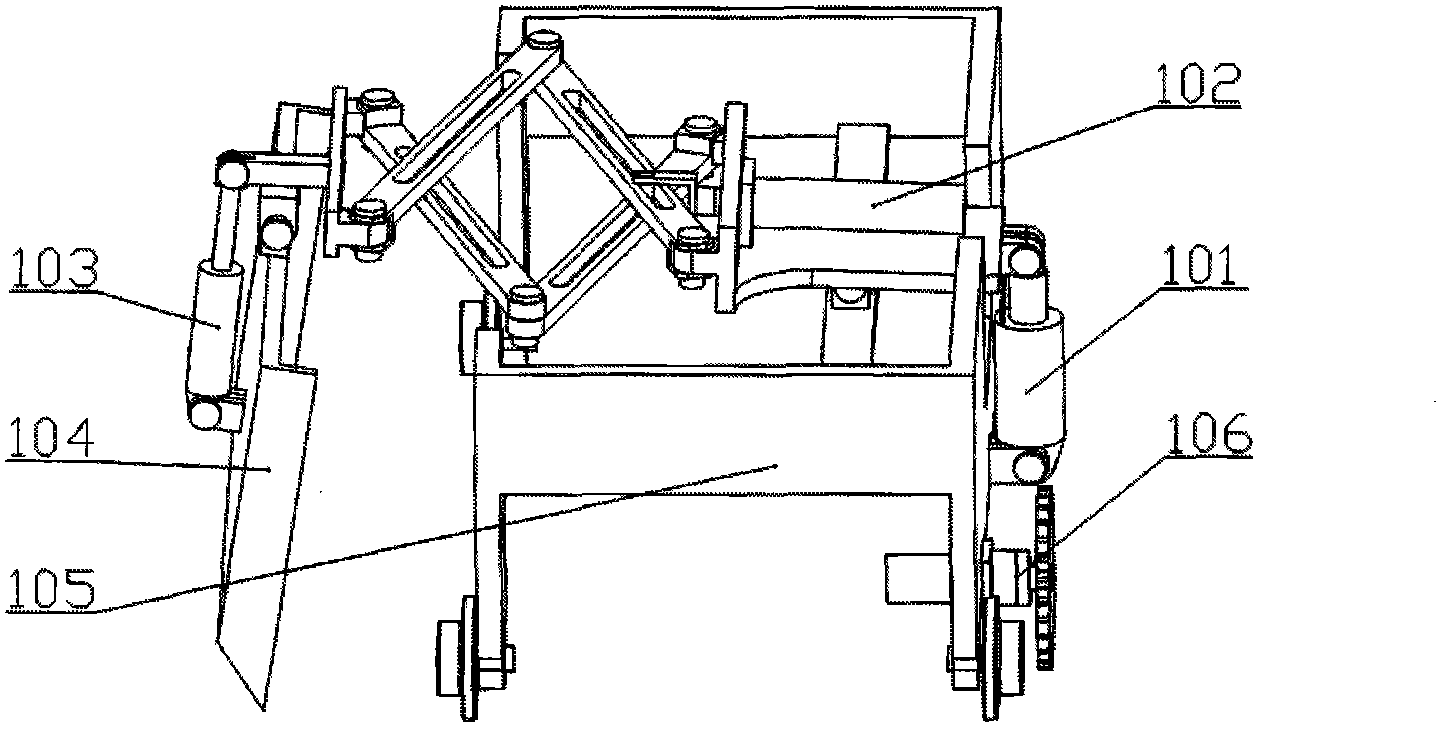

[0041] figure 1 Shown is the structure of the disclosed coal raking manipulator, which is mainly equipped with a pitching cylinder mechanism 101, a scissor telescopic cylinder mechanism 102, a shovel opening and closing cylinder mechanism 103, a shovel 104, and a travel gear mechanism 106 on the car body 105. .

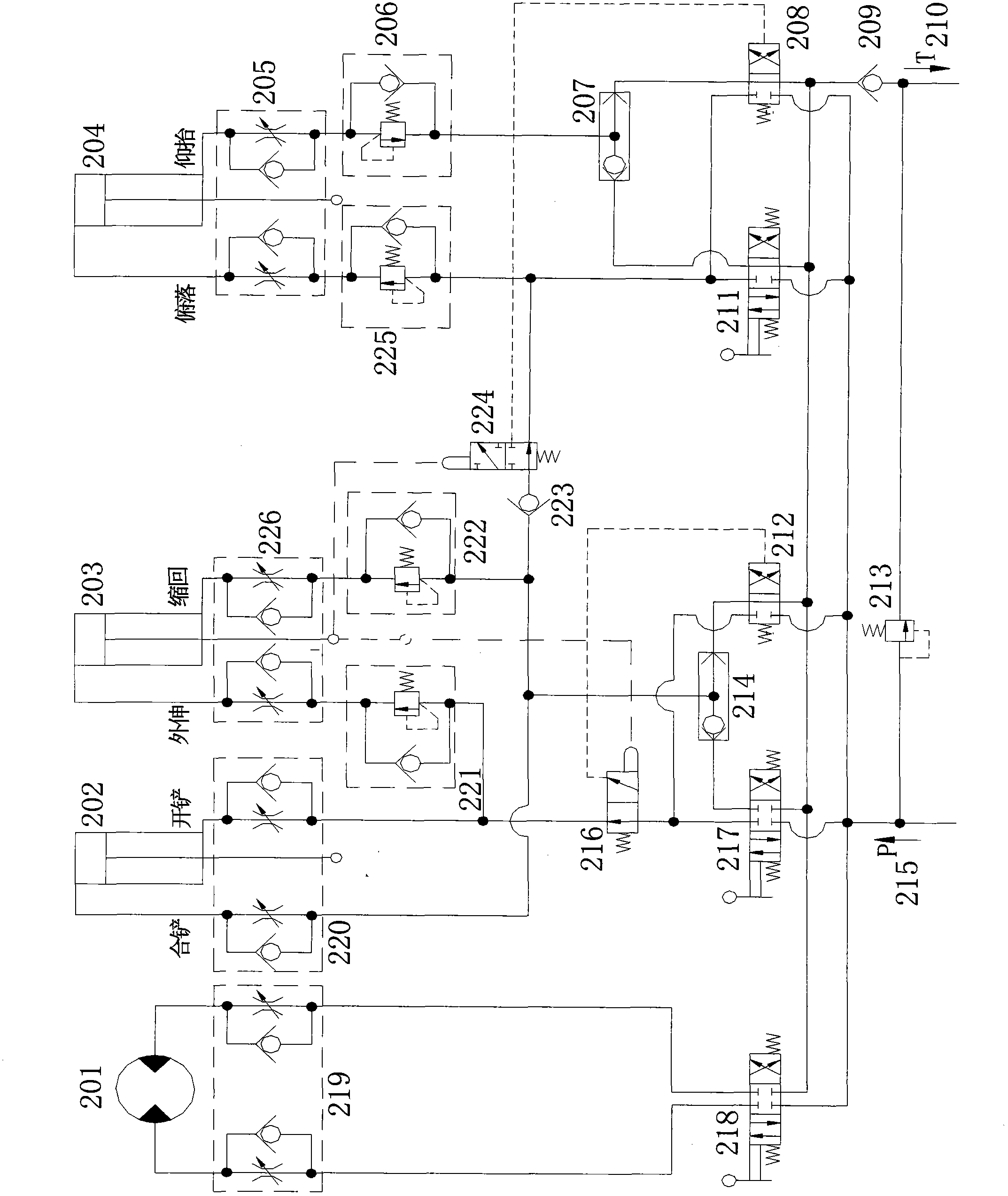

[0042] figure 2 The coal raking manipulator hydraulic control system shown is mainly composed of the main oil circuit, the walking hydraulic circuit controlling the traveling gear mechanism 106, the raking and shovel opening and closing hydraulic circuit controlling the raking and shovel opening and closing oil cylinder mechanism 103, and the hydraulic circuit for controlling the scissor telescopic oil cylinder mechanism 102. The scissor telescopic hydraulic circuit, the branch line oil circuit, the arm and shovel p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com