Recoverable anchor rod for drilling, anchoring and grouting and supporting method thereof

A technology for bolting and drilling anchors, which is used in the installation of bolts, earth-moving drilling, mining equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

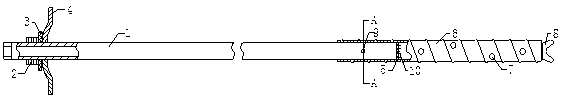

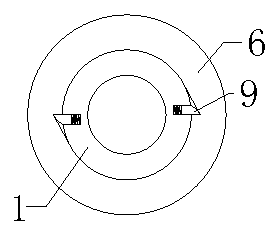

[0020] The recyclable anchor rod for drilling and anchoring of the present invention is mainly composed of a hollow threaded rod body 6, a drill bit 8, a hollow grouting rod body 1, a nut 2, a washer 3, a tray 4 and the like. The nut 2, the washer 3 and the tray 4 are sequentially arranged at the tail of the hollow grouting rod body 1. The hollow grouting rod body 1 is a hollow rod body with threads at both ends. The front end of the hollow grouting rod body 1 is equipped with a hollow threaded rod body 6, which is The outer surface of the threaded rod body 6 is rebar, the front end of the hollow threaded rod body 6 is provided with a drill bit 8, and the hollow threaded rod body 6 is provided with cross-distributed multi-purpose holes 7, and the hollow threaded rod body 6 is matched with the hollow grouting rod body 1 at one end. A self-locking lock ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com