Pilot-operated type solenoid valve for gas well wellhead and valve plug lifting mechanism

A solenoid valve and spool technology, applied in wellbore/well valve devices, wellbore/well components, earthwork drilling and production, etc., can solve the problem of limiting the use range of solenoid valves, limited valve core opening height, and affecting gas well output Efficiency and other issues, to achieve the effect of tight closing, large opening height and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

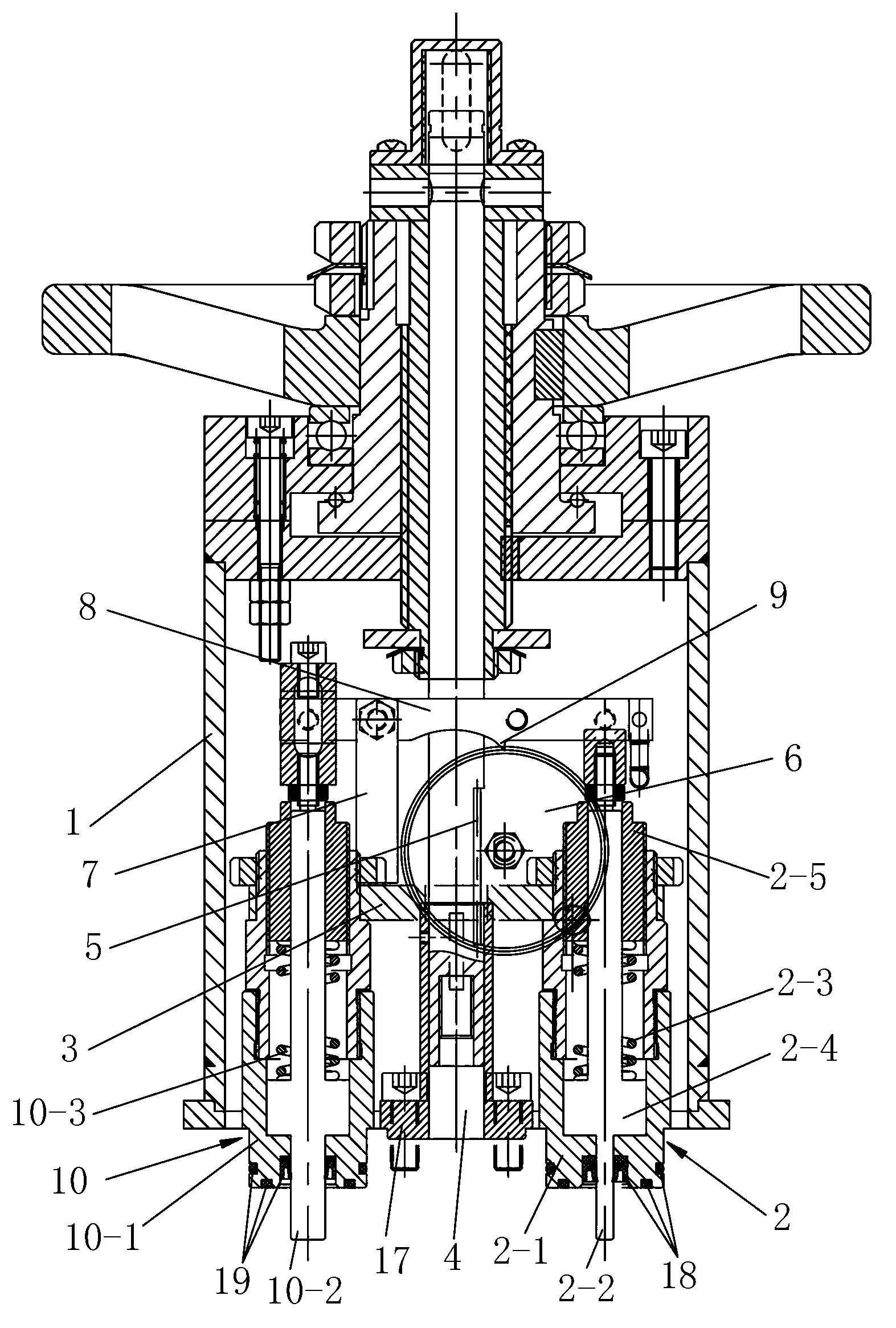

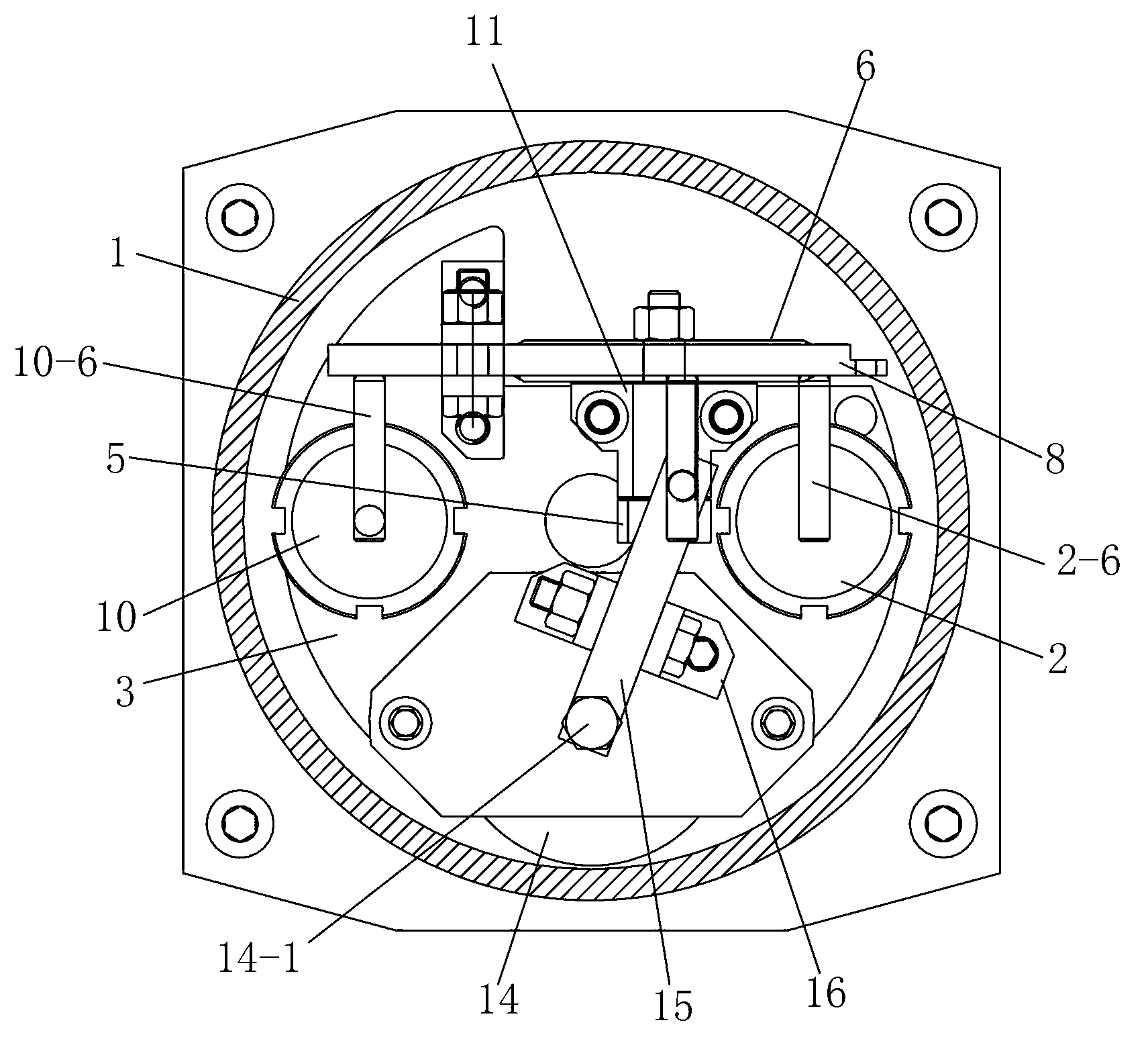

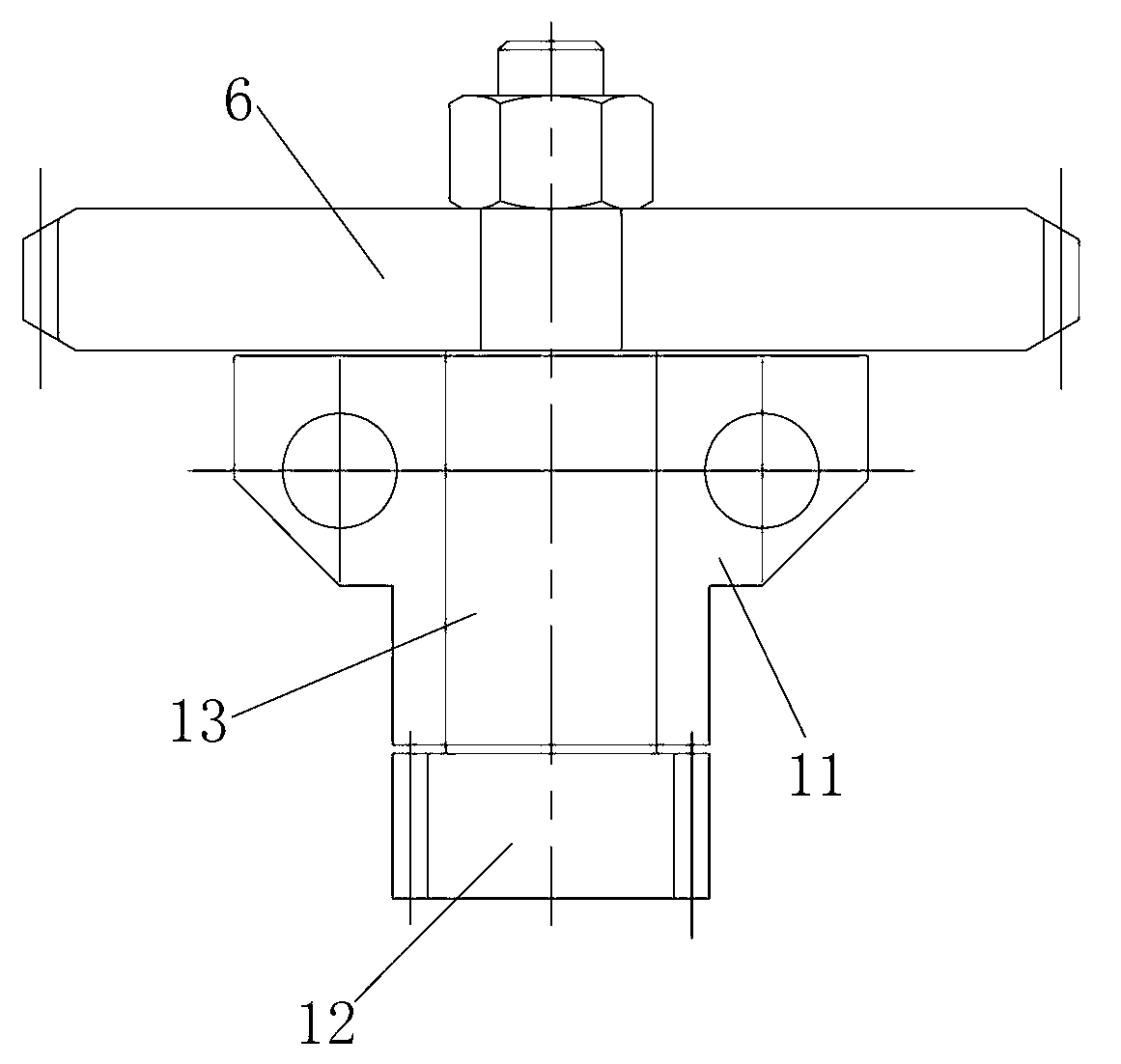

[0055] Such as figure 1 , figure 2 and image 3 A solenoid valve spool lifting mechanism shown includes a support plate 3 horizontally arranged above the solenoid valve bonnet 21, the upper end of the lifting rod 4 of the solenoid valve main valve core 24 passes through the support plate 3, and the lifting rod 4 A rack 5 extending along the length direction of the lifting rod 4 is provided on the top, and a connecting body 11 is arranged on the upper surface of the supporting plate 3, and a transmission shaft 13 perpendicular to the lifting rod 4 is rotatably installed on the connecting body 11. , one end of the transmission shaft 13 is equipped with a gear 12 meshing with the rack 5, the other end of the transmission shaft 13 is equipped with a ratchet 6, and the upper surface of the support plate 3 is vertically provided with a support rod 7, so The upper end of the support rod 7 is rotatably connected with a long lever 8, and the connecting point between the support rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com